I’ve been giving a lot of remote lectures the last couple of months. And I’ve done another podcast, which hasn’t aired yet. And there are the questions that come in connected to my YouTube Videos, The Weaver Sews. Lots of opportunities for Q&A. I would say that the one question that I get asked over and over, (other than, how do you cut into your handwoven fabric, now I can happily say there is a video for that…) is, where do I get my inspiration. I think people really care about this issue, they want so badly to produce great work, and original work, and really want to know how others interpret what’s around them into something awesome.

Some of it, actually a large amount of it is confidence. And confidence comes from doing. Confidence means that even though you are in uncharted territory, and you have no idea how this is going to work, or if it will be great, or awesome or really stupid, confidence means no fear. So what if it doesn’t work, it is cloth. So what if it isn’t great or even stupid, you never know if you didn’t try. And whether it is great or stupid, something is always learned, something tangible, that will serve you on the next grand adventure.

So I just started a new project and went through all the steps to come up with something I think is going to be great, but maybe won’t be, but I don’t care because it will serve my purposes. I thought I’d go through my thought processes the last couple of days so you see how I think, and that it isn’t so special or brilliant or inspired, it just is a series of steps that lead me on an adventure. I sometimes can’t decide, so I’ll send a photo to my weaver friends, we message daily, or I’ll ask my daughter, and sometimes she actually gets me to make a decision by allowing me to talk through what I’m thinking and why. And a good portion of the time I don’t take anyone’s kind advice. I just go with my gut.

First, and I’ve said this over and over in my talks and podcasts and videos, I weave when I’m in the mood to weave, when I have an idea and something sparks my curiosity. I never have a plan as to what I’m going to do with it. This just happened with the last warp I did, which I pulled off a couple days ago, tossed in the washer and off it went onto the shelf. There was no plan for what it will be. I weave to weave, and I make fun cloth. What I do with it down the road (probably clothing) remains a mystery. I was determined to finish this off this past weekend. I had lots of help.

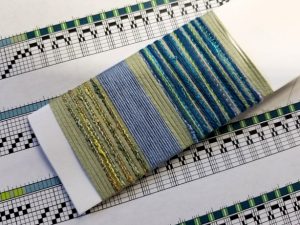

I had done a similar cloth for Silk City Fibers, the draft is available here for free. I called the fabric Confetti, and I liked the idea that you could take a fatter yarn and float it over and under two weft picks having a stable ground underneath. I rooted through my hand dyed yarns and found a whole bunch of skeins of some natural colored silk I probably bought from a friend a number of years ago. A fat silk.

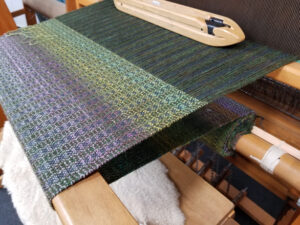

So I sat with a draft, and figured out how to make all these skeins work in yardage, and I have no idea what I’m going to make with it. It will sit there and age like fine wine until the mood strikes. Here it is washed and finished. I definitely want to play with the stripes and have them intersect on the diagonal. That would be fun…

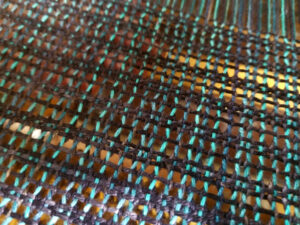

Meanwhile, I wove this fabric last year, another one using Silk City Fiber Yarns, the draft is available here for free… It is called Shadow Tapestry and uses their old standby variegated chenille, with their newer yarn, a Cotton/Bamboo combination with a lot of loft, soft and spongy. I combined the two in a Shadow Weave Structure. Apparently my beat was less than perfect and the end result was that each repeat was just slightly off from the previous repeat, which is why I encourage people not to do weft repeats when weaving yardage.

But there is always a way…

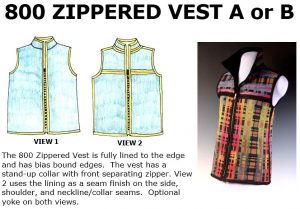

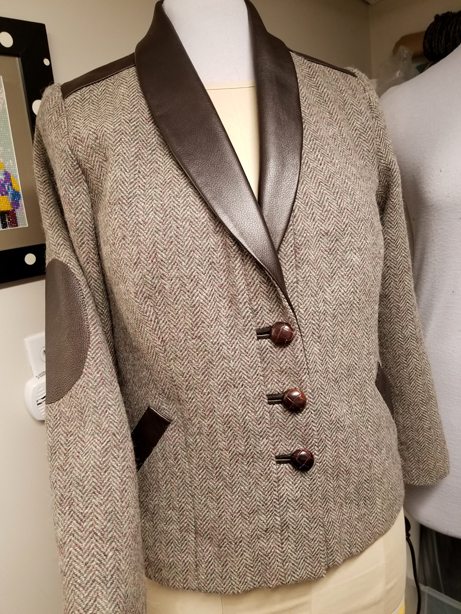

So we have finished up the video series making a couple of my 200 jackets, showing step by step how to do some pretty complicated things. The last installment of that series should drop Friday. We have one more in the can, the one for the “Ask Me Anything” segment that should air the following week and then I need a new theme. I figured that the 500 vest and 600 walking vest, were pretty close to the construction of the jacket, with a couple of differences in how the armhole and lining are treated, and I could probably knock them out in a video. And I’m scheduled to teach a three day remote class using this vest as a background for my piecing technique, so it would be helpful to have a video to direct students to areas of construction they might not understand in the printed directions. I should make a vest next.

So what should I use to make this vest…

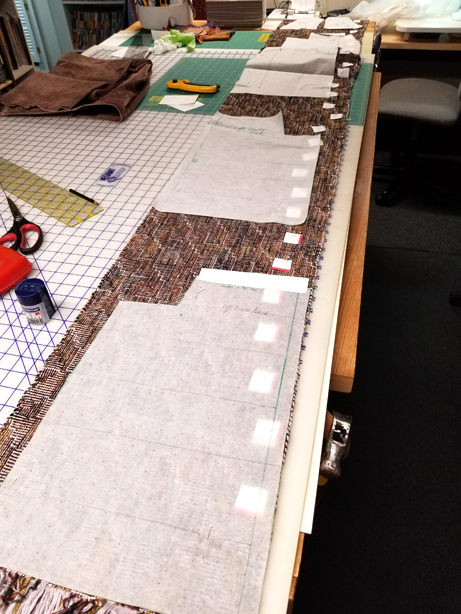

I looked through the handwoven fabrics I had on the shelf, and a couple of commercial fabrics I could justify using (sort of like a handwoven), and the Shadow Tapestry fabric jumped out at me. So I rolled it out. I’m not even sure at this point if there is enough, but that never stopped me.

I tried on the samples for my 500 vest and yeah, quarantine has been tough, food plentiful, and exercise non existent. Yes, I’m now walking 4 miles every morning and starting to work in the yard, but that doesn’t help me with the 10 pounds I gained last year. So definitely cut a larger size in the lower half…

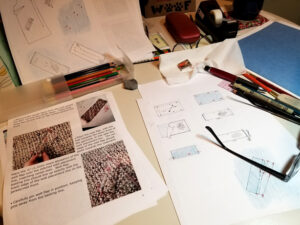

Once I have a pattern I can play around with the fabric. There is definitely not enough to do the bands. So I’ll have to come up with a plan B for that… And the layout is tough, I’ll have to have a center back seam, and that means that matching these mismatched shadow weave blocks will be a challenge. I actually measured each repeat to see if I could find like areas. Cutting a yoke would help, the lower part could be cut from one area, and a full yoke across the back would fit across the fabric, EXACTLY. Complete luck.

Which means piping between the lower body and upper yokes.

Last month in a disgusted clean out of all of my skirts and pants that no longer fit, there were some treasures that I hated to toss, so I thought of them as new raw material. Surely that skirt had enough fabric for the trim on something. And my beloved leather pants. I didn’t wear them last year, because I never got out of my pajamas, but I couldn’t get them on. So I lovingly carried them to the studio and put them on the shelf. They would find their purpose one day.

I thought I found their purpose, because they went beautifully with this handwoven Shadow Tapestry. I would cut them into bands and piping and it would be gorgeous. I started to remove the lining in the pants, and realized that years ago, leather of course gives and they had gotten too large for me and I had taken them in substantially in the center back. So I let them out. And they fit. And I’m over-joyed. I loved these pants. I could do a whole blog about the history behind them. But largely this meant that I couldn’t use them for my vest.

Plan B…

Back in 2007 I made a vest out of a very small warp someone gifted me, I wove off the warp and turned it into this lovely vest, which I adored, but sold in a guild sale to one of my guild mates. It was called Native Woods.

I lined it with a woven alpaca pile fabric, the kind from a vintage zip out lining in a men’s trench coat. The pile fabric was gifted to me by someone, the card exists in my design journal from 13 years ago, but I always loved that bit of pile fabric trimming the exterior edges of the vest. I sort of missed that vest after I sold it.

I have the scraps. And I think it is enough for a neck band and pair of armhole bands. And the color is good. But that means I have to come up with something else for the piping. In the middle of the night, I woke up with a voice telling me to check if there was any leather left from the Harris Tweed jacket I just made.

In the morning I checked, and I had enough in the scrap bag for piping for the two front yokes and the back yoke.

Which left the lining…

I rooted around in my stash, and pulled out a couple of contenders, one of which is here. A lovely silk print, maybe from the old Waechter’s Silk Shop in Asheville. I mourned when it went out of business. I use to raid their remnant bin whenever I would visit.

And then I spied this silk blouse I had just added to my stash. Back in January, armed with a dozen masks, I drove to Maryland to help my 89 year old mom move to a smaller apartment in the senior complex where she lives, after her husband, my step dad passed in December. It was a busy week, and as we moved her clothing, she culled some of the pieces she didn’t think she would ever wear again. My mother and I are not even close to the same size and shape. But she had in the “to be given away” bag this lovely silk shirt, not anything I would fit into or wear, not my style, but it was silk. And silk is silk. So I took it and added it to my fabric stash.

And so I pulled it out and put it next to the Shadow Tapestry fabric and my eyes lit up. It was unexpected and fun and though my daughter didn’t like it, she liked the first choice, I just thought it was perfectly timed and meant to be…

So now everything is cut out, and I spent the day assembling the parts. Tomorrow I will write the script and Friday we will shoot the complex parts of the construction. I don’t know if the fur bands will be successful or not, but I won’t ever know unless I try. I can always take them off and replace them if I change my mind. Then I can shoot a video on how to rip out handwoven fabric…

And of course I had help, this morning when I came down to start constructing this is what was waiting for me, letting me know that he kept the pile warm and it was all ready to sew. This cat makes me laugh… He is sitting in my lap as I type…

Anyway, this is pretty typical of how I go through the process of deciding what to make. The fabric came about because Silk City developed a new yarn and asked me to test it and see what I could do with it. I asked for a cone of it along with a variegated chenille. I don’t know why when I looked at them I thought Shadow weave. I hate weaving anything with two shuttles. But I did, and so far it is working out. I’ve got so many threads of ideas, like seeds that germinate, and it is a process getting that little seed planted and see what sprouts from it.

Stay tuned…