Please Forgive me dear readers, no wonder I’ve been getting letters to make sure I’m still alive… I remember well Saturday night Catholic Church confessional when I was a kid, “Bless me Father for I have sinned, it has been six weeks since my last blog post…”

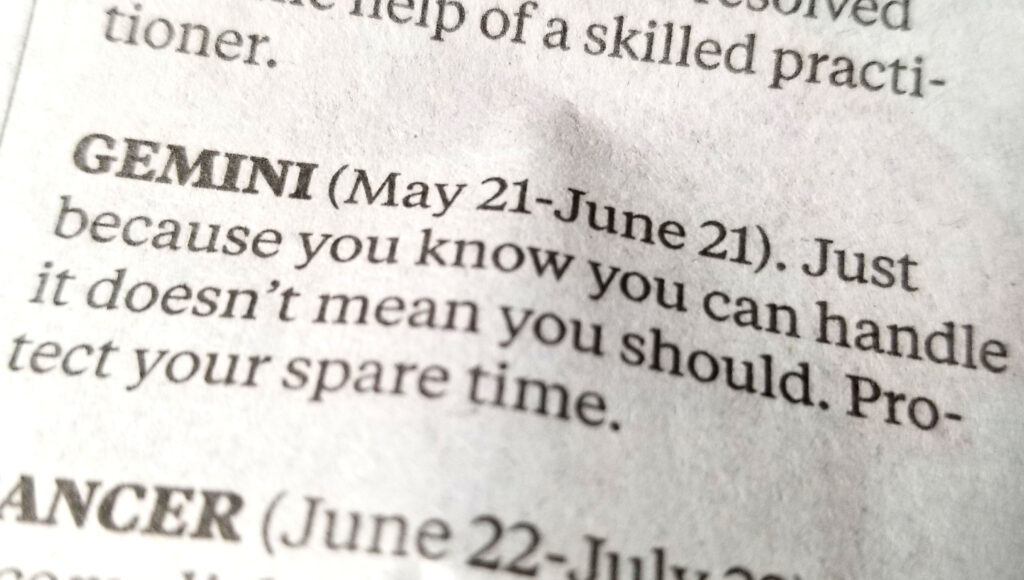

At the beginning of the month I caught this horoscope in my newspaper. Once in awhile I’m brought up short.

I need that reminder frequently.

I’d love to say that life in retirement is blissful and easy and boring. Yeah, no. I only retired from teaching on the road. I didn’t stop my calendar from filling up. I wanted to avoid this photo below, a photo I shot before I loaded my car to teach 8 classes at the NY Sheep and Wool Festival 9 years ago. It popped up on Facebook as a reminder…

I need these constant reminders that as chaotic as my life is now, it was much much worse…

I did take on a number of private students this fall. I’m pouring a lot of money into producing the YouTube videos, and paying my daughter a salary to make them happen, and I could use the income. (No, I don’t make anything off of YouTube, I’d need a couple million subscribers.) And I wanted to see what it was like to be in my space, using my equipment and supplies to do what I love.

And I’m enjoying the experience of having students in house. Cooking for different types of diets is a bit daunting, but I’m managing that, good skills to develop. But the calendar is rather full, one group leaves, another one comes in. That should slow up in another few weeks, but I also, in my quest to learn all the things, signed up for things I didn’t really have time to fit into the schedule. They were remote right, so they should be able to just fit right in… Between the student on Saturday, and teaching in Michigan on Monday and Ontario on Tuesday… I’m finding the need to print my schedule out hourly. That’s a first.

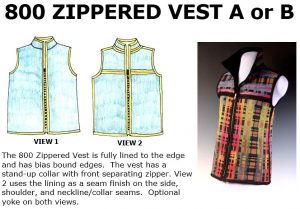

Still, no regrets… My guild was sponsoring a workshop with Jennifer Moore, whom I adore, the expert on double weave structures. For those that aren’t weavers, double weave means you are weaving two (or more) layers of fabric simultaneously, one over the other. There are advantages to this, but our focus was on weaving blocks, where the layers could change place, side by side. And the warp was her famous Rainbow warp, I used 4 ends of 8/2 Tencel as I moved through the color wheel.

Though I did have experience with double weave, this was a fun and challenging workshop, and I finally was able to get a warp on the new to me 25″ Macomber that I rescued and rehabbed. It wove like a champ…

And while I listened to a guild presentation last week, a different guild than the one that sponsored the double weave workshop, I sat and made cordage from leeks (the green parts), which I had sliced very thin lengthwise and let dry, giving a little spritz to soften them up when I was ready to use them. I can’t tell you how much fun it is to make cordage for basketry.

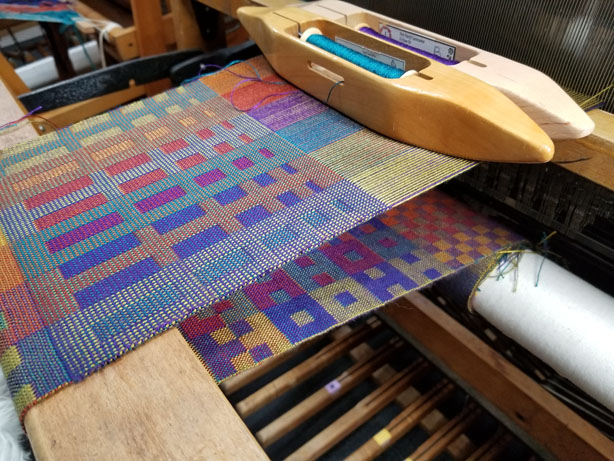

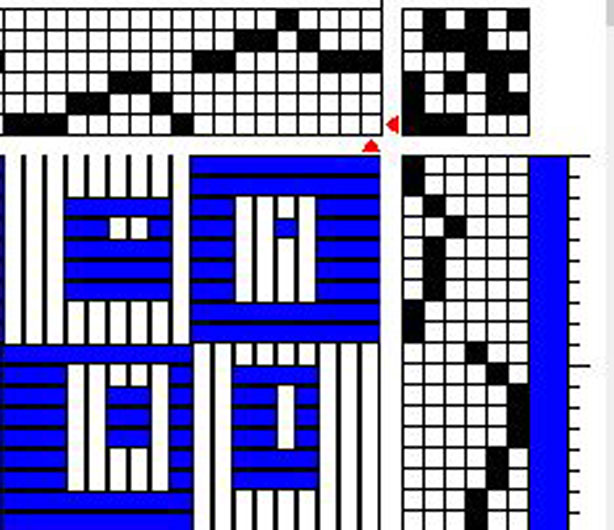

And in my spare time, I’ve been mulling over a draft I got from a friend, it has been making its rounds. This one is for something called Drunken Squares. It is a wicked cool fabric, and the draft was sent to me in the form of a profile draft. If you aren’t a weaver, skip this paragraph, it won’t mean anything to you. If you are a beginning weaver, this is a profile draft, meaning it isn’t something you can weave. You have to substitute each block in the threading and treadling with an actual structure. Each block is a unit. What you put into that unit depends on what structure you want. And since this is a six block structure, I thought I could do it with my 12 shaft loom. I tried, for a month. I got it to 10 shafts, and then when I spent another week or two I realized I could actually do it on 8. Most of my friends have done the draft effortlessly with 16 shafts. I don’t have that many. I plugged the profile draft into my weaving software (Fiberworks) and went to the block substitution tool. I worked for hours. I ended up with a tied weave, on 8 shafts, but it needed 14 treadles. I have 10. So I worked for hours more… In my spare time.

I got something I thought would work, 8 shafts, 10 treadles using more than one at a time. And no, I’m not ready to share the draft. I worked too hard on it.

I wound the warp, and went to my small 25″ 8 shaft Tools of the Trade floor loom, and looked at the treadles, and decided that this poor little loom, which I’ve had since probably 1982, could use a really good treadle scrubbing. I used a magic eraser, they are amazing for removing years of gunk, and gave the treadles a good polishing with my go to loom feed, Howard’s Feed and Wax. Even though my poor little loom still has its nose a bit out of joint since the acquisition of the Macomber, my treadles are very happy.

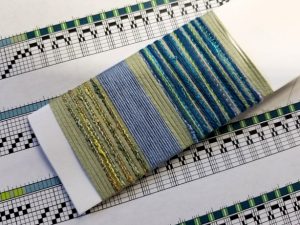

I beamed my warp. This is 10/2 perle cotton, in colors I had on the shelf. I had to drop one stripe to fit on my 25″ loom, but that’s OK.

And I got everything working and started to weave. I did it. There is such a personal triumph when you focus on something really challenging, determination keeps me going. I refused to admit defeat. And it worked. I did it. The drunken squares are really drunken rectangles, but I didn’t care.

While I was working on the loom next to it for the doubleweave class, I glanced over and thought, duh, just change the size of the blocks… ’cause that’s what we were doing in the doubleweave class. There are days I’m freakin’ brilliant, and there are days when I think, where did I leave my brain?

So I did another block of the repeat, and now I have real drunken squares. I remember years ago working on a two shuttle structure and having the shuttles constantly falling in my lap. And I designed a fix… This is a small loom with a small weaving area. So I took the second back beam (there is a second warp beam which automatically comes with a second back beam) and I slipped the cover on it I had made years ago, inserted a 5″ wide plastic ruler, and slipped the whole thing on the front to make a shuttle rest. I’m amazed I found all the parts considering the studio move.

And we are back to filming videos again for my YouTube channel The Weaver Sews, after a 6 week hiatus. Each video takes about 20-25 hours a week between my daughter and me, to produce. In my spare time… hahahahahah!

I finished filming the videos for my summer shirt. Just in time for fall, which has been delightfully summer weather… Handpainted skeins circular wound into an ombré effect warp. I sell this draft on my website… Also, the pattern is my 1000 swing dress cut into a shirt length, with the neck and in-seam button-down placket (no buttonholes to make!) from my 700 or 1700 Tunic. Those patterns are available in my eShop. Videos will soon be released on how to do the collar and armhole facings, last week’s video drop featured the in-seam buttonhole placket.

I planned this fabric from a few handdyed skeins while my husband was dying, worst week of my life. Took everything in my brain to focus on anything but what was happening to our lives. I’ve held onto this fabric for five years waiting for it to tell me what it wanted to be. I can’t tell you how proud I am of this shirt. I did add shoulder epaulettes, since I couldn’t get the shoulders to match. It is one of my favorite cheats. The contrasting fabric is a heavy weight linen. Here is a photo of the original skeins I used to create this fabric. I called the fabric Chaos. Fitting…

And so my retirement life isn’t any less chaotic. And as I vacuumed and dusted my weaving studio this afternoon, I thought about how much, as chaotic as it is, I love my life. There is always something calling to me, wanting to be designed, engineered, played with, created, or even cleaned, cooked or washed. And now as I cook I think, gee, can I use this for making a basket? Will it make cordage? And the animals always demand time. I’m never never never bored. There is a lot of life to cram into my remaining days and I want every minute I can get. Because we never know. I want to learn all the things, do all the things, and be all the things, in my spare time…

Stay tuned…