I’ve taught most of my adult life, in one form or another. Inspiring others to do for themselves is incredibly rewarding, watching that process of cause and effect, and seeing a student run with creativity, putting their own stamp on the information I have given, it all makes my heart sing.

It would be really great if I could take a workshop with myself once in awhile…

I’ve already mentioned in previous blogs, my quest to reinvent myself, explore new areas and adventures, and keep myself as busy as possible in this challenging year. Challenging for many reasons, not the least of them is my son’s deployment to the middle east. I’ve needed to stay distracted and creative.

And of course, one of the biggest distractions of the year has been replanting my property with thousands of native perennials, bushes and trees. I spend hours out there watering, weeding, and watching bugs, bees, birds (I even saw a small praying mantis) and the activity in general that makes an ecosystem, which I’ve largely ignored up to this point, actually felt irritation, in that it is one more thing calling to me.

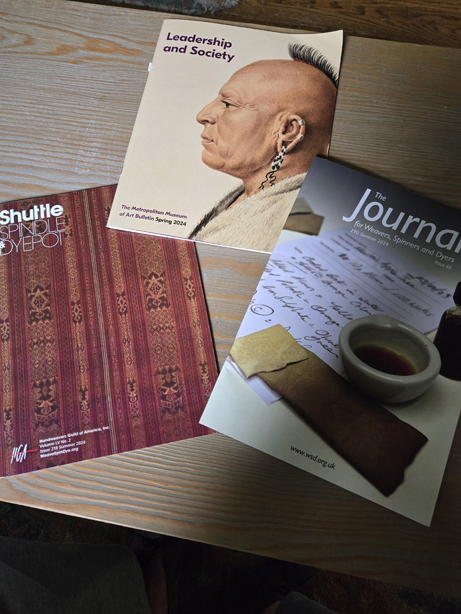

Things are starting to bloom, to mature, and I’m beginning to think about fall, and harvest, and when and where to do all those things that I thought about last spring. I’m largely in uncharted territory here. I know enough to know I don’t know what the heck I’m doing, but yet, I know I have to start somewhere. I’ve been taking workshops all year, in natural dyeing, eco printing, indigo dyeing, and even making a willow chair, which I talked about in my last blog.

I’m armed with a stack of books in basketry, in eco printing, in natural dyeing, in native plants, in pollinator gardens, and there is a thing as my dear friend Robyn Spady says, called Analysis Paralysis…

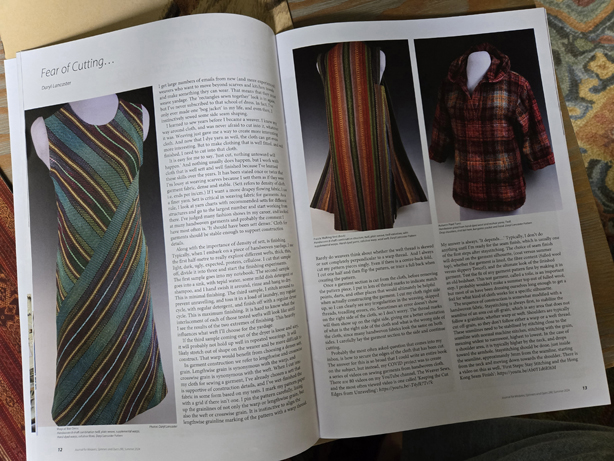

I would tell my students, if you want to get good at something, like making garments from your handwoven fabric, don’t expect the first thing you make to be incredible, prize winning, worthy of a Convergence fashion show. You have to start somewhere. You have to learn to fit your body, you have to learn to use your equipment, you have to learn the perks of your cloth, you have to learn what your body can and can’t do (yet) and personal ergonomics, studio set up, or lack of one, all of those things require a journey. But you have to start somewhere, and you have to keep at it, and discover for yourself. Going to YouTube and searching for a topic, and hoping that person will show you exactly how, might get you pointed in the right direction, but you still have to get on the horse and start the journey.

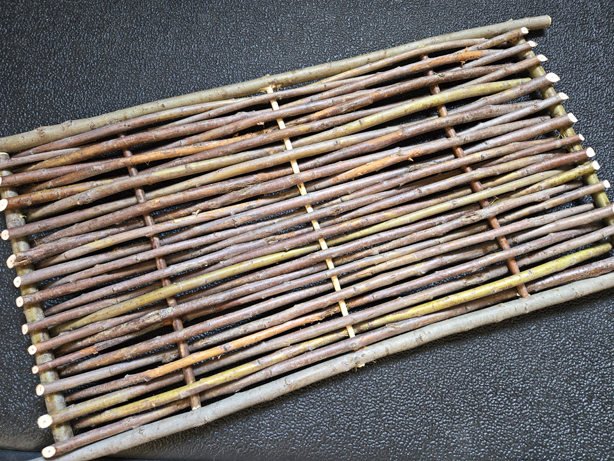

I will be taking a class starting next Friday, at Peters Valley in basketry. It is with a basket maker I adore, and I’ve taken a class with him before. This class is in free form basketry. I thought, though it isn’t required (materials list is, bring your creativity and a water bottle) that it would be great if I could bring some cordage I made, and in fact, I need to do something with all of last year’s shed full of flag iris leaves that have been dried and stored. There will be a new harvest coming…

So I started making cordage, soaking a few leaves at a time, making 2-3 yards in a sitting, and I’m getting a lovely little stack. I’ve since added a few more yards since I took this photo.

I took an indigo dye workshop with my guild a couple weeks ago (sodium hydroxide vat) and at the end of the day, tossed in a silk scarf blank, thinking I could use it for eco printing. As I’m out watering, I’m thinking, I really need to start harvesting some of these leaves, the peonies are on the way out, and I really need to harvest and dry, or just use them. And every time I eat an avocado, I save the skins and pits, and store them in the freezer. The bag fell out the other day. It was full.

So, I decided to put the books down, and just do it. I grabbed a bunch of wool skeins I had bought, and mordanted them with Aluminum Sulfate. Except, I was using a burner I picked up used, and didn’t really know the settings, and ended up boiling the wool, and to my embarrassment, partially felted six skeins. I felt like a complete beginner. I’m not into watching pots, but a watched pot never boils?

After I removed the skeins from the mordant, I tossed in some silk lengths for scarves, tone on tone silk jacquard, with a pretty watery design in it. And I tossed in a yard of a silk/cotton lining fabric, just because, I’m curious.

Annoyed with myself, I took the avocados out of the freezer and someone told me to grind up the pits. I pulled out my food processor, with the grater disk, and realized that I needed to thaw the pits first. Duh… Even a Cuisinart won’t grate rocks…

I put them in the sun, and they thawed within the hour, and I was able to grind the pits up, and tossed it all into a soup pot and didn’t care if they all boiled away, except that I read later that boiling them takes away the pink color. Sigh…

I got a pretty peach color, with two skeins of wool, one mordanted and one not (I read that avocados don’t need a mordant), and I added one of the silk lengths.

And it seems with all foodstuffs, that the color isn’t really stable, or so I’ve read. So once washed, they were kind of dull and uninspiring, and one of the skeins is partially felted… There is that. But I can always overdye…

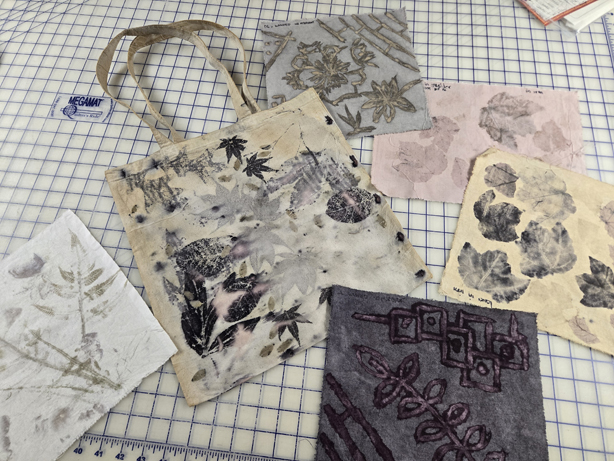

I took the peach colored silk jacquard length, and went out and harvested a bowl full of cool stuff. Cotinus (smoke bush), Japanese maple, ferns, Oak, Peonies, Rose leaves, Redbud, and I tossed in for good measure some onion skins.

I used an iron blanket, a length of cotton I had, dipped in Ferrous Sulfate, and laid on top. Rolled the whole thing up and steamed the bundle, for maybe an hour, forgetting that I had to go out to an appointment, and didn’t want to just walk away from a steaming roaster. So I turned it off and a few hours later came back to it.

The results were hugely disappointing. Other than the orange pops of the onion skins, there was almost no imprint on the silk.

Though the iron blanket was pretty. But not what I was going for.

I grabbed the indigo dyed scarf, and tried again. This time, I just went back to basics, and sprayed it with 50/50 vinegar and water, and tried again.

Super disappointed, there was no imprint at all except for the few coreopsis flowers I tossed on at the last minute.

Still, there are many avenues to take here, so I started over, mordanted the indigo scarf with aluminum sulfate, and dipped all the botanicals in Ferrous Sulfate before laying them onto the scarf.

I covered it with an iron blanket, another length of cotton from the stash, and finally, I got something I can work with.

The iron blanket actually had some color in it, but I am starting to think about different post options, and thought, what if I tossed it into a dyebath, and so I did, with a handful of onion skins. I always have those available. The onion skins and the ferrous sulfate combined to make a lovely green. I haven’t washed either scarf, I read I should wait for a few days…

Meanwhile, I’ve ordered a bunch of dye extracts and chemicals from Botanical Colors in Seattle. They will take a while to get across the country. Unfortunately I haven’t been able to locate a source for aluminum acetate, everyone seems to be on back order. I’m patient. I have enough to keep me busy.

But I’m starting to get excited, see what I can try next. None of this is what I actually want as a result, but it is a start. I won’t make that award winning piece for awhile, if ever, but that isn’t the point here. I’m learning, exploring, wondering what will happen if… And that is the point. And all of this is coming from my gardens. Except the chemicals…

Of course, having learned my lesson, I now baby-sit pots all day long. I thought I was off the hook watering my gardens the last couple of days, since we were supposed to have torrential rains tonight into tomorrow. It looks like most of it will go south of us. So that means back to watering tomorrow, but I had a couple days just sitting and watching pots, and working on quilt appliqué block number seven.

There are nine blocks in this quilt, a project my mom bought in the 90’s, and never got to do; asking me last year if I would make it for her. Her arthritis is too bad now, she is 93. I agreed and it has been an amazing project. The coolest puzzle I’ve ever assembled. Once the 9 cat blocks are finished and assembled, there is a huge vine that meanders through the entire quilt, the trunk of which starts with the cat I’m working on, his claws are scratching the trunk, or will be. I can’t completely stitch them down until the rest of the quilt is together. It is the perfect project to work on, that and cordage from my invasive flag iris leaves, while I sit and watch pots so they don’t boil.

And I did order an induction burner from Amazon. I can actually set the temperature…

Stay tuned…