Most of you know at this point that my son has been deployed to a place in the middle east that is challenging. My goal this year was to stay so busy I wouldn’t have time to think about that challenge. And so far that has been my life saver. The exhibit was one of the greatest things to happen to me professionally. It is down now, or rather the 41 dress forms have been moved to a smaller gallery, the Titan Gallery, around the corner from the main gallery. That leaves the main gallery for their end of semester student show. I had wanted to get there to see it. At the beginning of May, the full exhibit will return, exactly the way it was, to the main gallery, with another reopening May 9th, coordinating with the Teen Arts Festival. The exhibit will remain up until the end of August. I expect to be there the final couple days before reopening to check that all the labels are correct and all the clothing hanging the way I like it. Lots of zhuzhing up…

Here are a couple images from the Titan Gallery.

The show will reopen with a formal opening from 6-8PM on May 9th, that’s a Thursday, and the hours of the show, from what I understand, are M-F 9-6, and probable Saturday hours, but that’s not confirmed.

The response has been overwhelming, carloads of friends, guild members from across three states, friends from my High School in South Jersey, I’m touched and honored at the support. What a beautiful way to end my professional career, allowing me to do fun things that retired people do. Like weave, knit, garden, volunteer, you know. Have fun…

I made the decision last fall, that I really needed to remove the invasives from my property, and so I hired a fantastic landscape designer, highly recommended, to basically redesign my property. I mentioned this before in my blog. She has been remarkable. Covered in mud at the end of the day, she is out there with her one helper, hauling dirt, hauling trees, moving boulders around my yard. This is just one area that she has cleaned out and reworked, and the hundreds of plugs of perennials will eventually be added. My entire property will basically look like this but full of perennials. My only job is to keep this watered and weeded until everything is established. No problem she says with complete confidence…

Meanwhile, I had this beautiful vine covered gazebo that became invaded by a horrifically invasive Akebia vine. Which I did not plant. It killed everything else, except one pocket of cross vine, struggling for any kind of survival. I gave my daughter permission to start ripping. 11 bags later to the brush recycling, and the structure had been so compromised that we decided to purchase a similar domed structure that would help support the crossvine and any new ones we planted, and anchored the two together. It will be a few years, but I’ll have my gazebo back.

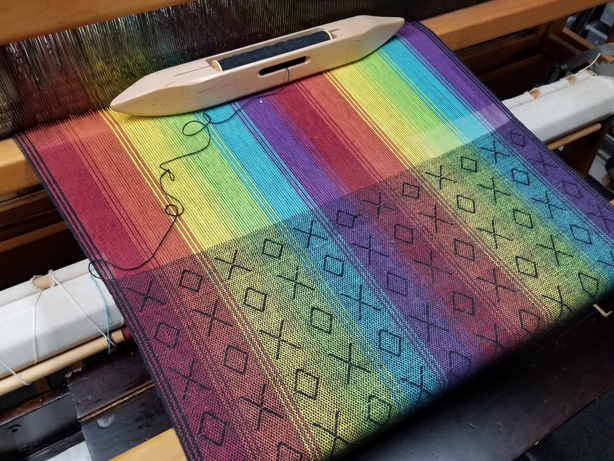

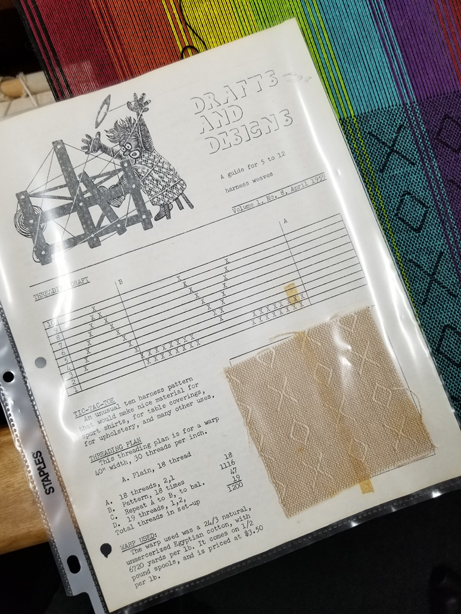

So while all of that is happening, I signed up for a three day workshop through my guild, with Rosalie Neilson, on Rep. Rep is a warp face structure, with alternating thick and thin wefts. It is great for rugs, and bags, and I just wanted to hang with my weaving buddies. Day 2 was entertaining in that we were about 15 miles from the epicenter of the earthquake that struck western NJ. It was felt up into Boston. They are still talking about it. 4.8 magnitude. Not common on the east coast. At first I thought the building had been hit by a truck, but the rumbling and shaking kept happening. It took us a long time to figure out it was an earthquake, and so we ran outside. I have to honestly say, it was an incredible experience to feel the earth under my feet swaying back and forth, like waves, subtle but very intense. I’ve never felt anything like it. It was a powerful thing to witness. We stayed outside for about 15 minutes and decided we were cold and went back to the workshop. No discernable damage, we kept close watch on our phones for any updates. There have been something like 85 aftershocks, none of which I felt.

We ended the workshop on Saturday, and though I still have warp left, I cut off what I’d done, and we all got to take pictures. I’ve done rep before, so I understood it, but I had never tried Warp Floats, which is a sort of turned Honeycomb structure, except both sides are the inverse of each other unlike weft Honeycomb. I want to try more of that.

Sunday, one of my guild buddies and I headed into NY to the NY Botanical Gardens Orchid show. It was of course gorgeous, and I couldn’t take enough photos. Their infamous glass house of course had other types of plants, and I’m always up for cactus and succulents.

Lots of inspiration here, especially for dyeing…

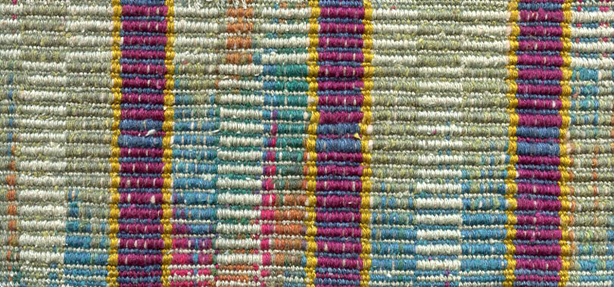

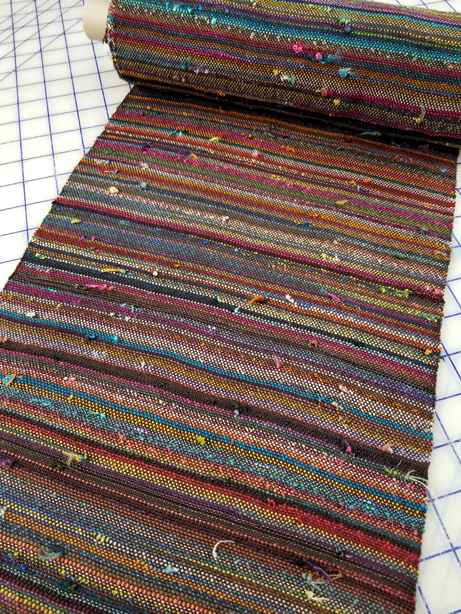

Meanwhile, because I’d pulled a lot of old work and scraps from the attic looking for things for the retrospective, I had piles of scraps, still, from the production years in the 1980’s. I hate to just toss all of it. I keep thinking that there has to be some fun thing I can do, some patchworky thing, besides all the ornaments, bags, totes, greeting cards, etc., I do already for my guild sale. These are not my best fabrics, these are plain weave, mixed warps, all from the early and mid-1980’s. But they are still valid fabrics. So I thought I might try my favorite sweater jacket pattern, and maybe a larger size, so someone bigger than me can fit into it at my guild sale. I started to lay out the fabrics in a blocky random way.

I have lots of colors in scraps of silk noil, that I made into bias tubes to put between the butted handwoven scraps, which were fused onto a backing. I added a layer of punch needle fleece, so when I stitch down the bias tubes, I’d be essentially quilting the jacket.

I wasn’t sure at first, but now that I see the back finished, I’m really liking it and can’t wait to see it as a finished jacket. There is a four part series of this piecing technique on my YouTube channel, The Weaver Sews. They were some of the last ones I recorded.

Meanwhile, I’m continuing work on the cat appliqué quilt blocks my mom gave me last year, something she wanted to start in the 90’s, but never got around to it. She asked me to make it for her. I was horrified at first, but then started playing around with it, and truth be told this is so much fun. I love watching each cat build from the fabrics they give you. This one is particularly challenging with all the fringy fur. But I’m finishing up quilt block 4 of 9. Blocks 1-3 are in previous blog posts. This cat is a Persian, and all that is left is the face, which has something like 35 pieces.

And in between all of that, I’m rehearsing for a concert in May, with my early music group. I love the music, Renaissance music is fun and fun to play, and this particular concert will also include music from video games like the Legend of Zelda.

I should have been at rehearsal tonight. But life sort of got in the way. You know, things happen when you are planning something else?

So Tuesday, I was running around shopping and packing boxes to send to my son overseas. He asked for some things like K-cups and snacks, and I’m a good military mom, and got right on it. Trying to fit everything into one box proved challenging, so I went out to our recycling bin for a second box. I was running up and down between floors, my house is 125+ years old and there are practically steps between every room. I came down carrying the second box and missed the last step and next thing I knew, I’m screaming in pain, and the indignity of it all, and please don’t let it be broken.

I did manage to get to the post office, to ship two boxes of stuff to my son in parts of the world that are challenging. I left the post office and knew at that point that it was broken. Three hours in the ER confirmed. I’m pissed of course, because I’m having fun, and keeping busy doing the things I want to do. I want to be in the gardens. I want to be at music rehearsal. I want to be weaving, and planning, and volunteering. The diagnosis is a cortical avulsion fracture at the dorsum of the navicular, with a possible fracture at the lateral aspect of the cuboid. Or in simpler terms, I broke the top of my foot.

They gave me a temporary splint, and a pair of crutches, and may I say that giving an almost 70 year old woman a pair of crutches is pretty dangerous. I almost killed myself a half dozen times on the way home.

I saw the foot specialist today, and in the corner of the waiting room was this really pretty fake hydrangea. I got a picture of it. I loved the colors. I’m already thinking it will be my next warp. The foot specialist put me in a boot, but wants an MRI, scheduled for Monday to make sure I didn’t tear the tendon coming from my ankle. I doubt it, and I’m in absolutely no pain. There isn’t much swelling, and I’m learning to navigate with this giant thing on my foot. Please don’t tell me I’m doing too much. There is no way I can sit on the couch with my feet up for anything longer than an hour or two. I just can’t do it. There is too much going on, animals to attend to, and too many fun things I want to do. So I will find a way. My next goal is to figure out how to get out in the garden, sit my butt on a cart, and continue pulling out invasives. A broken shoulder two years ago didn’t stop me, and a broken foot won’t either.

So I’ll be at my opening in a boot, I’ll give the Teen Arts Festival keynote address in a boot. I’ll perform at my early music concert in medieval garb, with a boot. I’ll take a workshop in natural dyeing at Peters Valley in a boot. And I’ll drive to a farm in south Jersey for a lecture on growing dye plants, in a boot. And I’ll do what I always do. And if I have to weave on a floor loom, I still have one usable foot. Mostly I’m working on table looms, so that isn’t an issue at the moment.

I’ll post the updated promotional materials for the exhibit once I have them, and I’ll keep you posted on the gardens and all my other adventures. The pieced jacket will probably be on hold a bit, because when I build these pieces I stand at the cutting table. Standing is a bit challenging at the moment, but I’ll figure out a way.

Enjoy your spring my friends, heavy rains due in tonight. Everything will get a good drink of water.

Stay tuned…