What a couple of weeks. I knew Mid-September through Mid-November would be jammed packed with all kinds of cool events, teaching opportunities, guild meetings, and general calendar must do’s but this is really crazy. I have vague recollections of just three years ago where the calendar controlled my life, instead of me controlling the calendar. Back in the spring, and even last winter, it seemed perfectly reasonable to book a couple of weekend workshops, since I’m not leaving the house to teach anymore, how difficult could this be?

Nothing here is difficult. And don’t get me wrong… I chose to participate in everything I put on my calendar. It’s just that the world opened up all at once, guild meetings started up again, a music group I once played for asked me to come back, Spinning and Weaving week, which is a weeklong series of weaverly events, all online, but like a conference all day long; teaching remotely every weekend, three weekends in a row for the same guild, and of course theater events, because those seasons started up as well.

By mid-November, this should all be quieting down, but for now, I’m tightening up my seat belt and hanging on tight!

Meanwhile, I taught remotely three weekends in a row for the Chattahoochee Guild in GA. A lot of old friends were there, and we had a great time. Last weekend we did a remote hands-on workshop and Leigh, a friend and workshop participant took this shot of the classroom, and there I am, larger than life. I of course couldn’t see what they saw, as I was viewing the classroom from multiple cameras strategically placed around the room. It was sweet when someone had a question and wanted to show me what they were working on, and they would go up to the screen to talk to me… We are all still getting used to this technology.

Meanwhile, I did manage last week, before the start of Spinning and Weaving Week, sponsored by the HGA (Handweavers Guild of America) to actually make a couple of pieces. I wove a fabric last year, all rayon, and it was sitting on the shelf just calling to me. There are a lot of competing voices in the studio, and sometimes the cacophony of who wants to be noticed more gets a bit loud!

So I wanted to see if I could draft this swing vest, based on a commercial pattern, using one of my own patterns. And I’m really happy with the results. I used my 1000 Swing Dress pattern and created this variation. I wanted to be able to use the selvedge of the cloth for the center front edge, and have it fall away in lapels. And fringe the bottom edges, so no hems. Eventually I’ll take my notes and recreate what I did and see if I can document it in a video.

I had extra fabric, and I thought it would lend itself to a bias top, so my 900 Bias Top pattern came in handy.

I still had extra fabric, and so I made this tote bag using my piecing technique, which I documented in a four-part video on my YouTube channel, The Weaver Sews. And there is still a stack of leftovers…

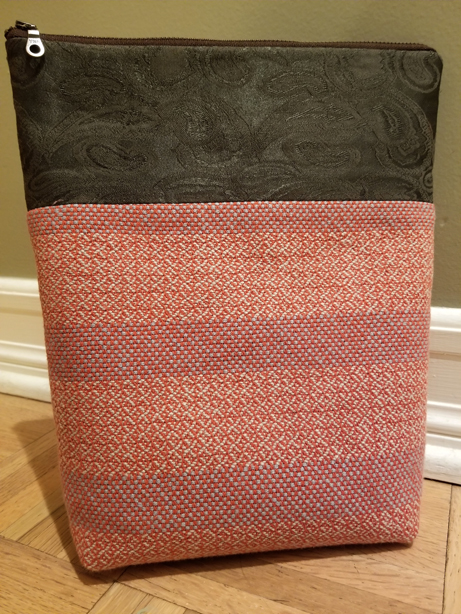

Meanwhile, while I had some free moments in the studio, I took a leftover section of the towel warp I showed last time and made this zippered bag.

So Spinning and Weaving Week is/was a lot of fun. Events all day long. Some really great speakers and studio tours. They featured me in my studio during Spinning and Weaving week two years ago. How I wish the re-play was available. I often meant to film my own version to put on YouTube myself. It is on the list. Which is growing exponentially…

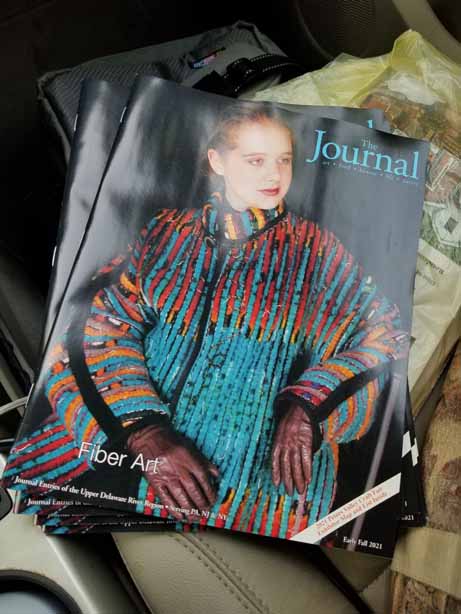

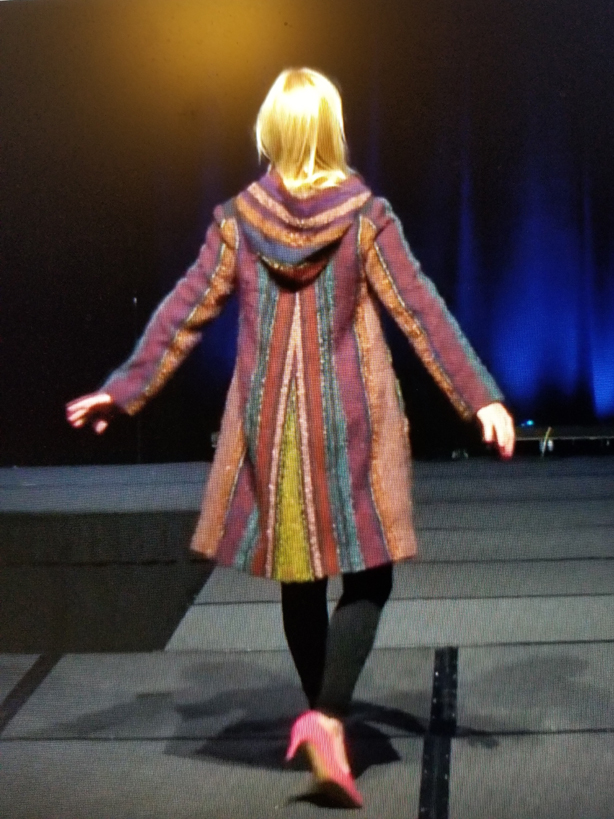

I was one of the panelists Tuesday night, for a session about getting into juried shows and the basics. It was great hearing the other panelists and their perspective on things. Friday night was really really special. There was a viewing party of the Convergence 2022 fashion show, where I had five garments as an invited artist, but I did not actually attend the conference, for many reasons, mostly because I was at a wedding in Virginia for the son of someone who has meant a great deal to me over the years. I had hoped the fashion show would be recorded, and I wasn’t disappointed. Seeing my five works walk the runway was just the highlight of my week!

And this morning, I set up my messy office, because I have sixty different things going on at once, into a video studio because this afternoon was the Strut your Stuff fashion show, and of course I registered for that. Meaning I would be modeling one of my garments for it. I pulled out the video lights and set up the good webcam camera, the one we use for taking videos.

And I was first up for the actual fashion show. So here I am modeling my double weave jacket I made earlier in the year. I included the second image because the running transcript was just too hilarious, Artificial intelligence just doesn’t get textile terms. “Devil Weed” should have been double weave, but Devil Weed works… I sort of got that vibe when I was trying to weave off the sampler last January with one arm…

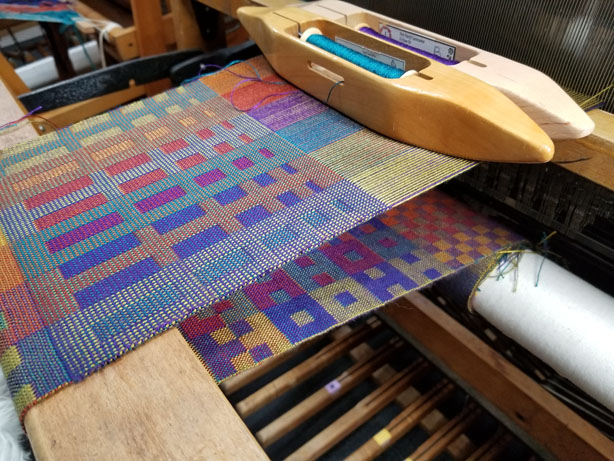

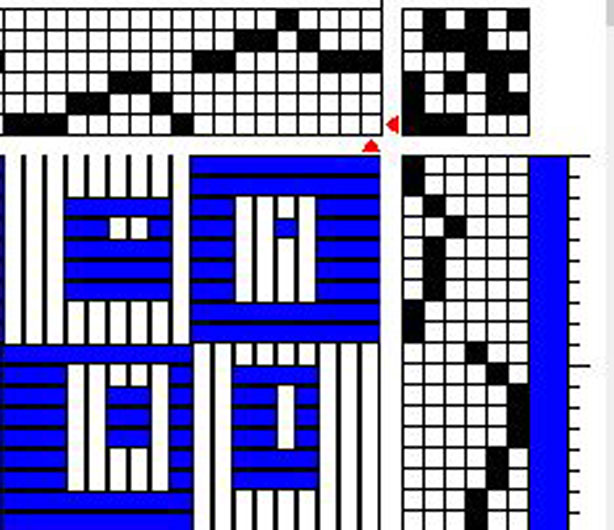

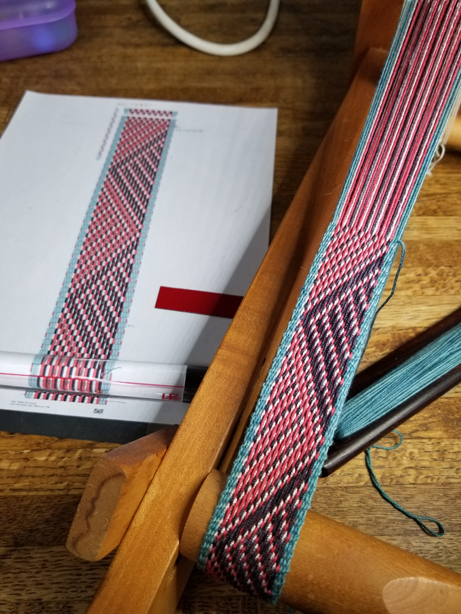

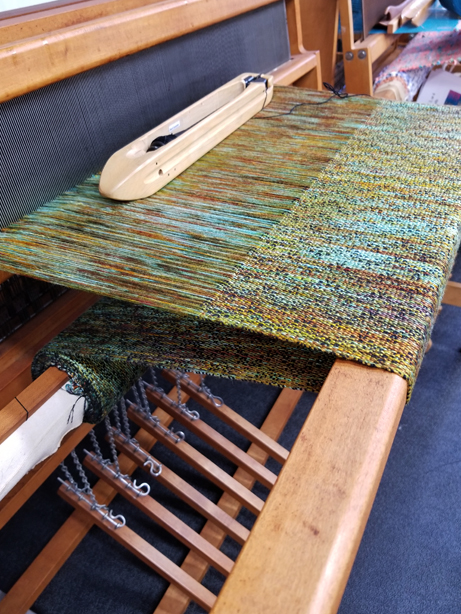

And Friday, in between sessions from Spinning and Weaving week, I took an online class through my guild with a weaver from AZ, Deborah Jarchow, on Clasped Weft. For some reason that technique has never crossed my path. It was fun, I sort of felt like I was dancing with the shuttles. I had set the loom up on Tuesday while watching Textiles And Tea, an online weekly interview, also sponsored by HGA.

And remember I mentioned the cacophony of looms and fibers and fabric and yarns calling to me? I had cleared all of the floor looms I’d been weaving on except for two. They reached out every time I walked by in the studio, as if to say, “Please won’t you sit down and weave with me?”

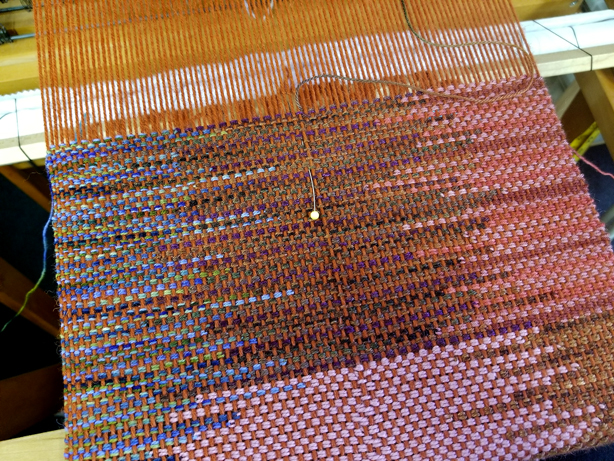

So I did sit down, whenever I had a few minutes. This is the ice dyed fabric I started earlier in the year, and I have no idea how much there is still to weave, because I started with 10 yards and it doesn’t look like anywhere near that on the cloth beam.

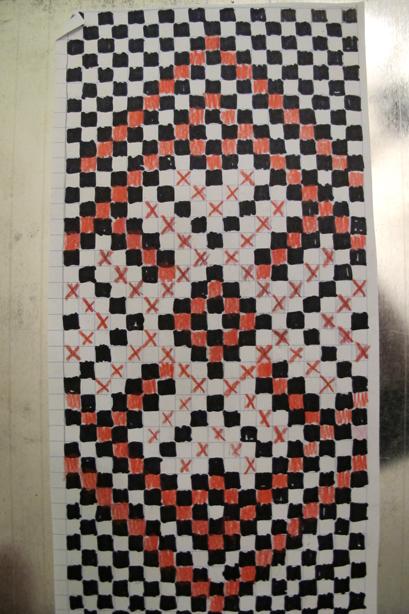

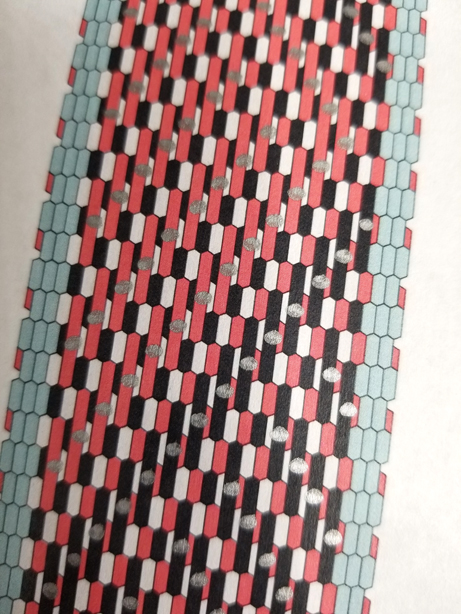

And my favorite loom (don’t say that too loudly, there will be a revolt) has a fabric I spent a long time working out last year, and I think I put on 8 yards of 10/2 cotton warp. So I’m probably over half-finished this very cool pattern called “Drunken Squares”. It has been that kind of a week.

Don’t cry for me dear readers, I’m having a blast. I just wish the blast was a little more like a pop, and less like an explosion! This will all calm down as the winter draws near. I have someone working on my yard clean up, nice to have people for that, and I was finally able to get my alarm system company to come and upgrade/replace and add additional smoke detectors, especially in the garage weaving studio. They had rate of rise detectors, appropriate for a garage, but not appropriate for a weaving studio with yarns stacked to the ceiling. So those finally got upgraded, but there have been workers in and out for the last week, and they will be returning yet again on Tuesday. We all just step around each other…

I teach next weekend for two days in Canada, again remotely, I’m still so amazed that this technology even exists. So it will be a busy week prepping for that hand’s on workshop. Wednesday night I have two different fun events happening simultaneously, which is unfortunate, but I can still do both, because one will be recorded…

Stay tuned…