I’m continuing on my attic cleaning and making more stuff for the guild sale with my mother lode of scraps of handwoven fabrics from the archives. I made two more squirrels, from leftover bits of mohair, and while I was working on the second one, I plopped the other one on the ironing board.

Mulder the studio cat of course had to check out something that looked suspiciously like what he hunts in the middle of the night…

And typically had to check out the back end.

Satisfied said squirrel did not pose a threat, and being of a soft mohair and cuddly surface, Mulder decided to curl up next to him.

The face pleading, can I keep him, can I?

Sadly he can’t keep him, because the dogs would destroy the squirrels and anything else I have that’s stuffed in about 10 minutes. They gleefully dive right into anything with stuffing. So Mulder can’t have his little buddy…

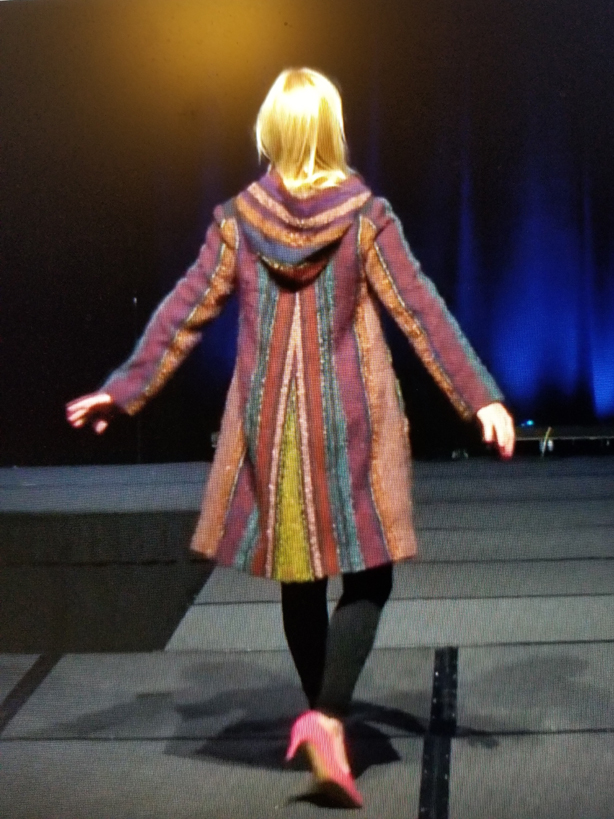

I’ve been able to create another jacket from the mohair scraps of a different colorway. I had a well meaning friend tell me they were really ugly, and that kind of stung, I rather liked them, and they were fun to make, and super functional, I’m hoping there is someone who will appreciate them at the guild sale.

Almost ready for the final pressing…

I worked out an alternative to the white mohair stocking ornament tops. I ran out of the white mohair fabric, so found a soft white yarn and just crocheted round and round…

And I cut out a dozen little bear ornaments for the guild sale. I spent hours looking through my vast button stash, trying to find three of something that would work for each of the bears, and getting them sewn on, making little “kits” so I can sit and put them together while on zoom meetings or listening to a podcast, or Textiles and Tea, whatever…

Of course my trusty studio assistant had to leap onto the ironing board and keep everything in order… Sigh…

I managed to make two of them…

On Sunday, a local sheep farm, part of the NJ Fibershed, held a community dye day. A lot of work for the teacher Pamela Jenkins, a natural dyer from Maryland, and we had dyebaths to use with our pre mordanted yarns, (alum and cream of tartar) plus a station for botanical printing (results were disappointing, I think better compression would have helped) and a chance to use an indigo bath using Polygonum Tinctorium Indigo, which can grow in this climate. Interesting thing was using fresh leaves, and puréeing them in a blender with ice. This is appealing to me, since I never wanted to start a fermented indigo vat. I don’t have indigo on the property so I’d have to plant some. I waited to rinse my skeins which were 65% silk and 35% wool, for about 48 hours, a suggestion by the teacher. They are now dry, and some of the color did wash out, but I’m sure the volume of dyestuff vs the amount of yarn/fabric we dyed, really wouldn’t yield strong results. Still, it is a pretty palette. Willow, fresh indigo, butternut husks, elderberry, hollyhock flowers, and artemisia.

The day after I posted my last blog I got this gorgeous bench in the mail. Or rather shipped. I ordered my custom bench from Walt Turpening exactly a year ago. I wanted the gradation in the woven seat. Walt custom winds the cotton cordage to achieve the gradation. We spent a lot of time with measurements, loom and body, to determine the best bench height. Unfortunately the two looms I expect to use the bench with, are both empty. It is on my list this winter to get them both warped so I can try out the bench.

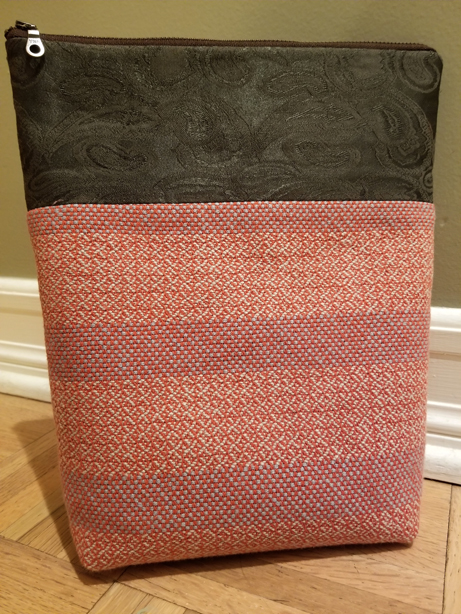

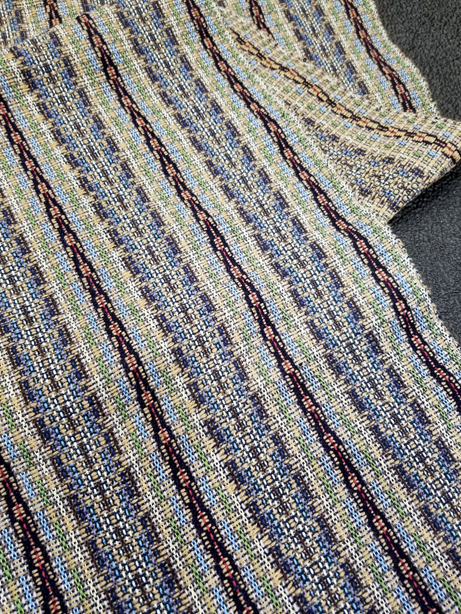

Meanwhile, I did finally clear the table loom with the Bateman blend. I didn’t get a lot of yardage, and it was really tedious. I’m happy with the results, and am thinking of designing a laptop slip case. I have one from Peru and want to copy how it was done.

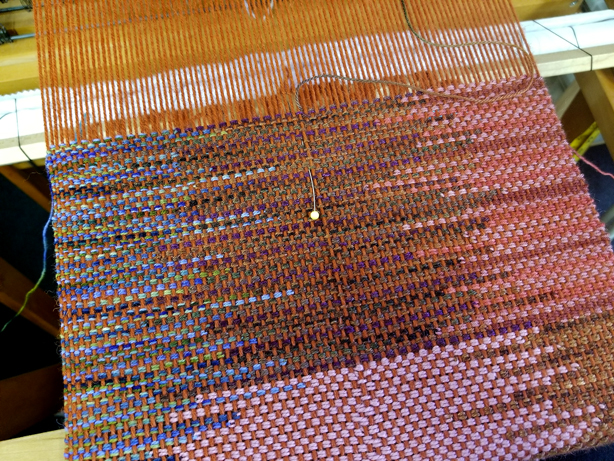

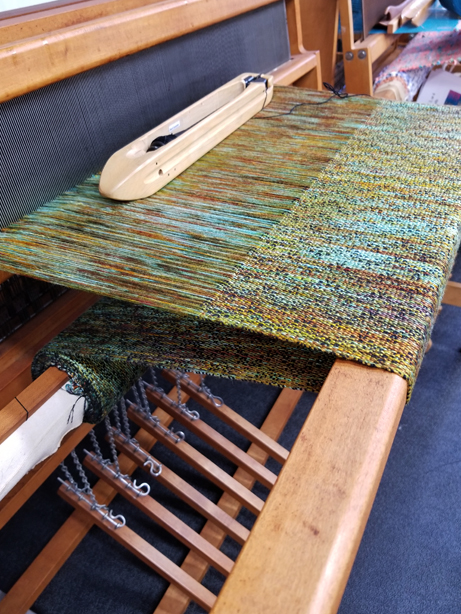

The loom next to it had a 4-shaft doup leno structure threaded on 8 shafts. I wrote an issue of Heddlecraft Magazine, (Issue #19) on doup leno, a technique where using half doups on shaft two allows the loom to crisscross certain threads creating an open airy structure that is very stable. The warp and wefts were hand-dyed cashmere so this is super soft. It seemed like the warp that never ended, and I finally got up and looked at my original drafting notes and realized I put five yards of warp on this little loom. Nearing the end of the warp, and wanting to squeeze in a couple fat yarns for headers, I discovered this cool tool that now I can’t live without. It is called a “Poke” Shuttle. I never heard of such a thing, but they were selling them in a few lengths at Red Stone Glen for their open house last June, made by Bluster Bay Shuttles. They just felt so lovely in the hand I bought three. The yarn just grips around the end of the shuttle allowing it to be able to poke through the narrow shed. It may have a different purpose, but I loved it for this task, and of course all Bluster Bay shuttles just melt in your hand…

I managed to get a long scarf and a pretty cowl from the handdyed cashmere.

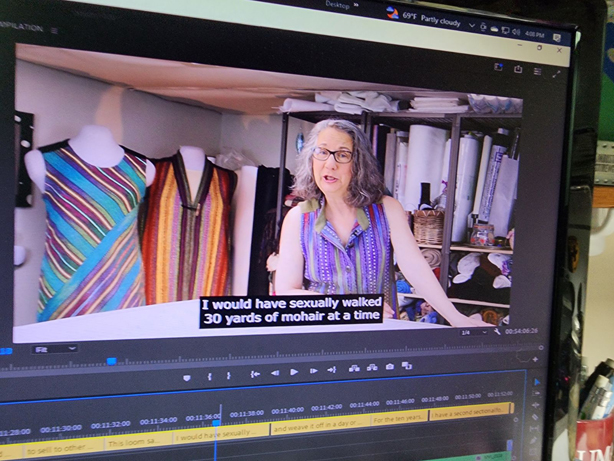

Meanwhile, my daughter is finishing up the edits in a video we shot last month, a one hour studio tour, which can be shown as a guild program. I wanted to recreate the studio tour I did for the HGA back in the fall of 2020 for Spinning and Weaving Week 2020, and wanted to document all the looms with warps. I am getting frequent texts with screen shots from my daughter down the hall with absolutely hilarious Transcription malfunctions. She first allows Adobe premiere to close caption the video, and then goes back and corrects. Textile terms in a transcription program are absolutely hilarious, looms become loons, and limbs, and lamps. Really, my diction is pretty spot on, you just have to increase your vocabulary sir! But the best Transcription malfunction I’ve ever seen is this…

It is supposed to read, “I would have sectionally warped 30 yards of mohair at a time”. There are no words…

And to wind up this blog post, I’ve had a lovely wonderful thing happen this past week. Something I can’t even wrap my head around, and keep pinching myself to see if I dreamed it or not. Long story short, assuming this all happens the way it is spelled out in the contract sitting on my desk, next spring, County College of Morris will feature my huge body of work both artwork and garments, dating back to the 90’s in their Main Gallery, a retrospective of sorts, along with video, audio, and a hands on component (aren’t you glad I have all those Structos) for about 6 weeks, transitioning to a smaller gallery for their year end student exhibition, and then back to the Main Gallery to coincide with the Morris County Teen Arts Festival in May, where I am to be the keynote speaker. Then the exhibition of my work will continue on until the end of August. It is especially lovely that this is my county college, and that both of my kids took classes there, and I even taught there for a semester way back. I have hosted two externs from there as well. So this feels like a perfect conclusion to a lifetime of work in the field. I’m especially touched that they asked me to give the keynote to the next generation of creative people. I have a lot of work to do on that address.

I hope the fall brings you beautiful colors, cooler weather, fun things to do with fiber, and friends to do those fun things with… And no Mulder, you still can’t have the squirrel…

Stay tuned…