I had every intention of following up my last two posts with two more, because I was only halfway through talking about the 64 named looms in my studio and what’s on them. I had intended to just jump right into the Structos, which I have many, along with the five 10″ 4-shaft Leclerc Sample Looms.

But the universe had other ideas. Right after I posted my last blogs, apparently as best we can piece together, Microsoft did one of their famous security updates, which caused havoc over at Google (don’t ask me how I know this), and the end result was a suspension of my main business email account I’ve had since I could get a domain outside of AOL. Somewhere in the 90’s?

Because I started traveling a lot, and my late husband as well, for our jobs, my husband found a way to reroute my main email, theweaver@weaversew.com, which was part of a hosted platform, to IMAP through Google, allowing me to look at my email in my laptop, or tablet. This is before the invention of Apps. So for years, that email IMAP’d through Google, and all was well. Until about 10 days ago. When it became inaccessible. At first my tech support thought it would come back, that Google was scrambling, and all would be well. Then he tried updating my email program, Microsoft Outlook, and nothing would bring back accessibility.

As I freaked out, people close to me reminded me that no one died, and that I hadn’t lost my files and records, I just couldn’t email anyone and anyone who emailed me, the emails would bounce back as no such address. Some people called or texted and asked, WTF? I gave them an alternative email. I desperately thought about who needed to reach me in the next few days, like the tour company sponsoring my upcoming trip to Japan, I leave in a couple weeks. I thought about all the guilds I’m working with for upcoming lectures and workshops. I spent days trying to change my email address so I could be reached. I lay awake a nights haunted by MFA which is a nightmare, meaning Multi Factor Authentication, meaning each address change I could actual make happen, took 15 – 20 minutes with all the 2 factor authentication, email confirmations, snail mail letters generated, texts and whatever. I get the need for security, but this was ridiculous.

Anyway, I’m not out of the woods yet. I worked with my hosting company Pair.com (which by the way is incredible) and they gave me a multi page step by step on how to redirect the email off Google back to a hosted mailbox through my weaversew domain. Sounds complicated, I can assure you, I’m not so tech savvy and these last couple weeks have been my worst nightmare. (I know, there are a lot of things worse than this).

My tech support, who is probably the best in the state, is not so easy to get, largely because he is the best in the state… While waiting for him, I kept trying to figure out what to do, working with tutorials, working with my hosting company, and I was able to get my email working again, but not in my preferred email program Outlook. I spent hours trying to come up with the right set of settings or protocols to make it work. It didn’t help that two of my three email programs were affected, and that there were 11,000 emails in my inbox on my main email address, and apparently 5,000 emails in my back up gmail account. So I spent hours filling and sorting and deleting until I was down to almost nothing.

I was finally successful in getting the right settings and got both email accounts to work in Outlook, but only on my office computer. I was afraid to even start messing with my laptop. One thing at a time. Turns out that was a good move, because by the afternoon yesterday, all of my email folders I’d created over the years, disappeared. Gone. I’ve never been so devastated, and I’ve had some pretty crappy things happen in my life. “You should have backed everything up” was not helpful, because I didn’t know how. Because my laptop remained untouched by my successful transfer of the emails back to Outlook, my daughter and I successfully spent until about midnight last night, with my tech support logging in remotely, retrieving 33 GB (no that’s not a typo) of email data off my laptop, dating back to 2013? maybe beyond… So I have everything, at least I think I do, and my emails are all functioning. If you emailed me and got no response, I lost about a week of emails, they would have been returned to you. Try again.

I’m waiting for tech support to help me reinstall the 33 GB of data back into Outlook, but I have it. And those 11,000 plus emails? They are all back. I’m thrilled and yet devastated that I have to go through them again and sort, file and delete.

I wanted to title this post For the Win, part 3, but I wasn’t sure if I felt like I won anything anymore. My filling all my looms seems rather anti-climactic. Nevertheless, I’m going to plow forth, and document anyway, so bear with me, because at the time (2 weeks ago) this was a big milestone for me. I’ve already cleared one of the floor looms I talked about in my last posts, so before I clear anything else, here is the list.

The first 13 Structos and 2 Leclerc sample looms are all set up and ready to go for a Learn To Weave program I do annually, and they can be used for any demos my daughter and I should encounter during the year. They live up on shelves around the studio patiently waiting. But they are all warped thanks to the class we taught at my guild in January. Their names, all after Star Trek characters, are “Yar, Worf, McCoy, Sato, Kes, Chekov, Uhura, O’Brian, Bashir, Troy, Scotty, Crusher, and LaForge“. The two Leclerc looms are “Neelix and Phlox“.

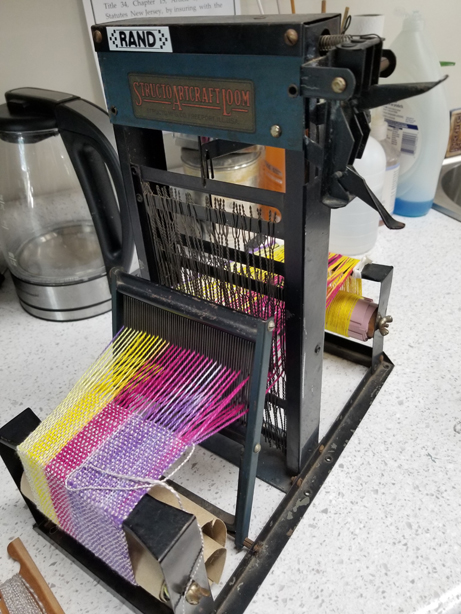

I also have a baby 2 shaft Structo named “Rand” that is only 4″ wide. I keep that set up with a handpainted warp, because it is really helpful to be able to explain how a loom works, with one that is set up, and help students identify the different parts of the loom.

The other three Leclerc Sample Looms are “Lursa“, a 4 shaft loom with a Huck sampler from an article titled “Stuck on Huck / 4 shaft Library” by Lynn Tedder from Best of Weaver’s Huck Lace, edited by Madelyn van der Hoogt.

“Bettor” has a 4 shaft doubleweave sampler from Jennifer Moore’s Doubleweave, but I used the threading from Ursina Arn-Grischott’s book Doubleweave on Four to Eight Shafts. I don’t know why I did that, for a challenge maybe? It hurts my head…

And “Hemmer“, which I talked about in a recent post, another 4 shaft loom, threaded in a straight draw (I think), intended for intense pick up. I found a booklet from Elizabeth Tritthart, historicweaving.com called 100 Horizontal Stripes. I love this one, and yes, it is really slow cloth, tedious as most pick up is, but you really can lose yourself in it and take pride in seeing the design build. And it uses up embroidery floss!

The remaining dozen Structos have cool drafts and structures on them, and I periodically pull one out and just weave. I can take one easily onto the deck and weave outside! The documentation on each one is important, because I have to remind myself each time what I’m doing, where I am in the draft, and how it even works. I have a guild mate, a relatively new weaver, who comes once a week to explore a different loom. It helps to teach it, and we work out together what a newer weaver understands and doesn’t understand.

If you are still with me on this… in no particular order…

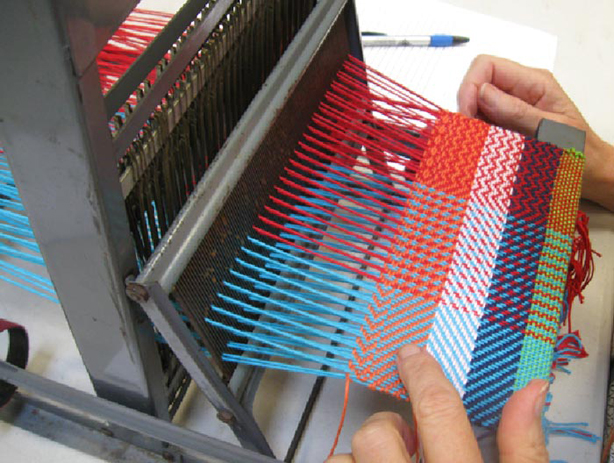

This little 2-shaft loom, “Chapel” was pulled out of the attic for parts, and I decided to set up a simple clasped weft technique after a workshop with Deborah Jarchow.

“Dax” has a 4-shaft Theo Moorman threading, which allows me to weave narrow strips of silk habotai, printed with an image in an ink jet printer, on a linen ground, using sewing thread as the tie-downs. I have a monograph on the subject, including step by step how I do this technique. This is a photo of pansies.

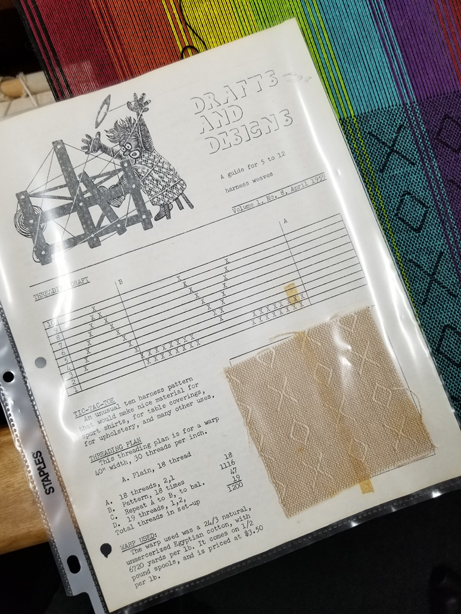

“Picard” is an 8-shaft Structo, threaded for a 4-tie pattern called Quigley, which I’d woven in a class with Madelyn van der Hoogt, and loved. This particular pattern was designed by Diane Click and is found in Tom Knisely’s Handwoven Table Linens book.

“Riker” has a 4-shaft overshot gamp, adapted from a draft by Robyn Spady in the May/June 2014 issue of Handwoven Magazine. Robyn does great gamps! I love Gamps, I define them as a sampler that works like a grid, each vertical stripe is threaded in a specific pattern, and each horizontal stripe is a specific lift plan, and the intersections of each creates stunningly different patterns.

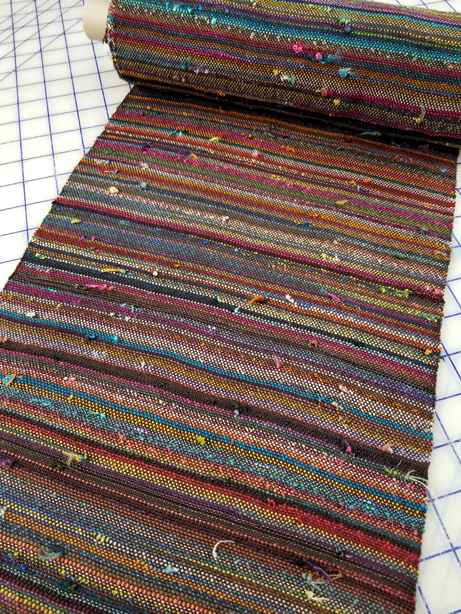

“Sulu” has a 4 shaft twill variation on a twill color gamp, again by Robyn Spady in Handwoven Magazine, November/December 2008. Getting the beat correct so the twill lines move at a 45 degree angle is harder than it looks.

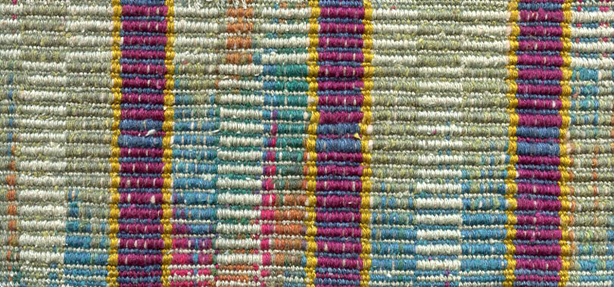

“Kira” has only 3 shafts. This is an amazing structure on only 3-shafts. It is a rug technique called Krokbragd, which no one can pronounce, but it is gorgeous, and also very tedious. This draft is from an article Vakker Mug Rugs, by Anu Bhatia, in Handwoven Magazine, May/June 2022.

“Archer” has a structure called Deflected Doubleweave, this one is on 8 shafts. I drafted this from the Marian Stubenitsky’s book, Double with a Twist. The real beauty of this cloth will come out after it is washed, when the yarns in the structure deflect into each other. The yarns are 8/2 Tencel.

“Burnham” has an 8 shaft Rosepath point twill threading. Carol Strickler’s book, A Weaver’s Book of 8-Shaft Patterns, has pages of little Rosepath designs, which are so much fun to weave.

“Kirk” has an 8-shaft Honeycomb threading, taken from a sampler in Malin Selander’s Weave a Weave. I’ve done three of the five variations, and within each of the variations are even more variations. These are really fun. They are named after operas, the first is Tosca, followed by Aida, and then Isolde.

We are getting there! If you are still reading I’m impressed. Remember I said a couple posts back, this documentary is for my benefit, a place to remember when I warped all the looms, with pretty pictures…

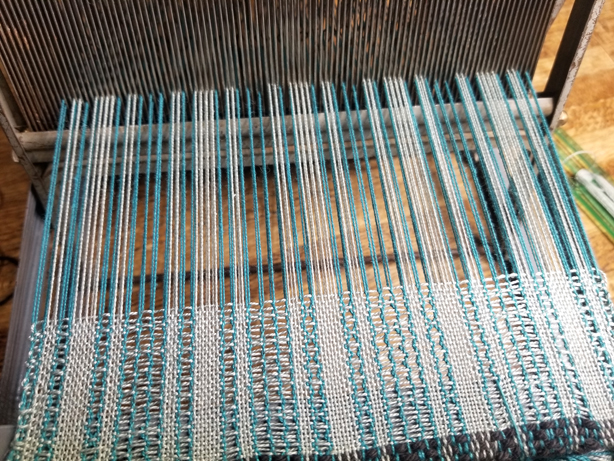

“Reed” has a 4 shaft Doup Leno threaded onto it. I wrote an entire issue of Heddlecraft Magazine Issue #19, on the subject. It is hard to see what’s happening in this small of a scale, but the lacy fabric is structurally sound because the turquoise warp threads twist back and forth because of a series of half heddles or doups.

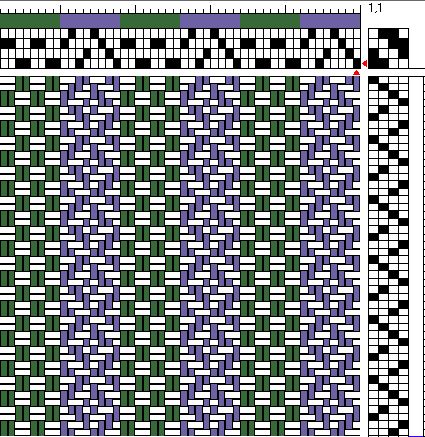

“Sisko” has an 8 shaft Shadow Weave on from a draft by Joanne Wood Peters. You can purchase the draft from Webs, it is Valley Yarns draft #199, called Shadow Weave Sampler. The yarns are 8/2 Tencel.

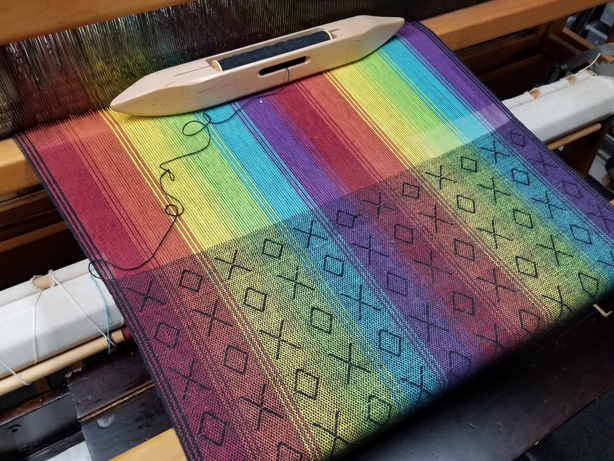

And last, but not least, (because there are ton more “other” looms, like Inkle Looms, still to document), is “Pike“. He has an 8 shaft Summer Winter motif, heavily adapted from a draft I think I got from Madelyn van der Hoogt in her class. I had to rework it to fit the size of the Structo.

I know this is a long post, but like I said, this is my journal and I wanted to document something I was proud of. And I’m glad I did, because I feel like the entire email debacle pales as I look at all these images. The data is there, it will eventually get migrated back where it belongs, mostly. My greatest joyful moments come when I figure out something fun or cool in the studio. They are what keep me getting up in the morning, that and the cat sitting on my face, and I’m so grateful to have this craft, the looms, the yarns, and the library of reference books to sit and pour over while I drink tea.

Stay tuned…