Seems like everything I do, from doctor’s appointments to purchases online to attending theater events, gets followed up with a survey. “Tell us how we did!” I hate them. I understand their necessity, and it would be great if the people reading them actually took the comments to heart, but mostly all this extra paperwork just makes my sitting in front of the computer even more overbearing, when I really just long to be in the studio.

When I do fill out a survey though, most of my opinions don’t fit the questions. If there is a box marked “other”, I usually click it, because in my life, most things require an explanation. I’d be terrible on a jury. I can’t answer yes or no. Even in a class, students ask me questions and my answer is always “It Depends…” Life isn’t black and white. Fortunately. It is in breathing living color, and there are lots of shades and tints within!

So with that said, I have a bunch of different “other” looms that didn’t get mentioned in my last 3 blogs, bringing the total of named looms to 64 I think. There are about 20 frame looms in the attic, for teaching purposes, and about a dozen hand made Schacht Inkle Loom knock offs, also used for teaching. And I think 7 still in the box Inklette Looms from my years of teaching, and I didn’t count any of them. I counted the ones I use, that I named, and so, because I wanted to document where I am at this point in my life, I’m going to finish out the list with the “other” looms.

Every weaver has probably seen or has a Peacock loom. I even found an ad for one, when I was assembling a lecture for a guild a number of years ago for their 50th anniversary. I researched what was popular in the day when they got started, and it was quite a representation of where we have been as a handweaving community.

So I have a little 2-shaft Peacock loom, named “Peacock” which is pretty unoriginal, but there you go. I use it when I have a young person visiting and they want to “try weaving”. I have refurbished it with new heddles, which I made with a jig, and new roller cords, with heavy duty shoe laces, and it is a solid little workhorse when in the hands of a new weaver wannabee…

A number of years ago, my daughter called me while I was on the road teaching, about a Glimakra Band Loom for sale from one of our guild mates. I told her she wouldn’t like sitting sideways, but she persisted and I gave her the money to purchase it. I was right. She hated sitting sideways, and immediately redesigned the way the treadles worked so she could sit in front. That would be my daughter! This loom is named “Seven“, not the number but the Star Trek character. On it is a gorgeous warp, which she put on, plain weave, but hand dyed yarns that are wound in an ombré effect.

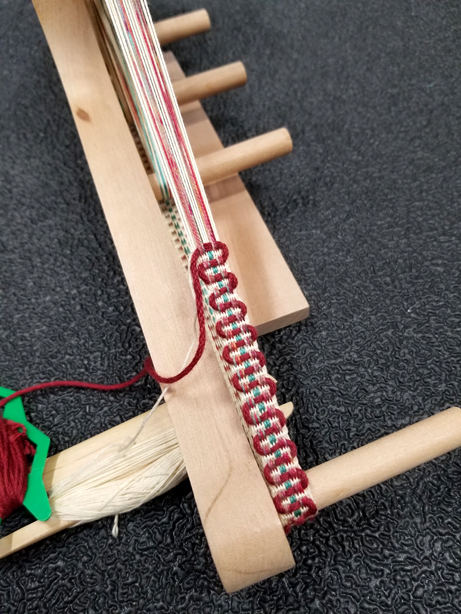

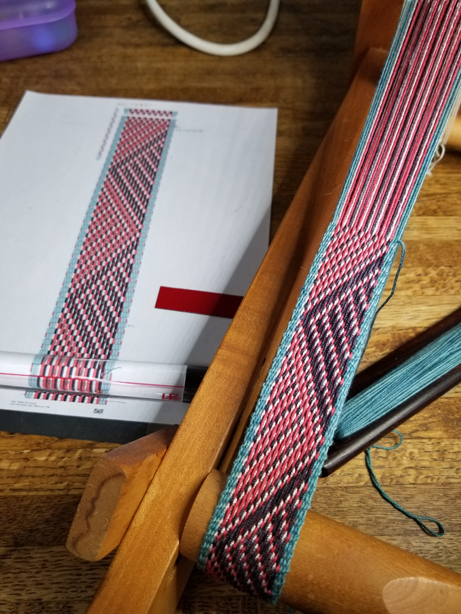

We own a card or tablet weaving loom, purchased from John Mullarkey years ago at a guild workshop. I’ve done card weaving many times, still prefer inkle weaving, and John and I have on more than one occasion done a “Battle of the Bands” performance at a couple of conferences. Tablet woven vs. Inkle Woven… That said, we have this loom, that my daughter warped a number of years ago, named “Rom“. I know the pattern is in one of my many booklets from John and I should be able to figure it out. My daughter isn’t big on accompanying paperwork. So I’d like to finish it off, in one of my outdoor weaving stints.

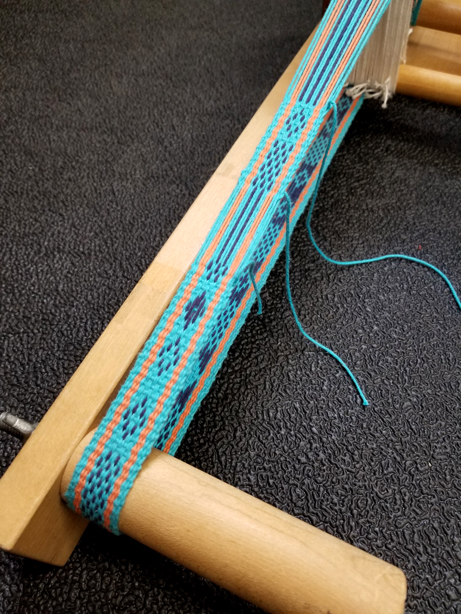

I also blogged recently about my Gilmore Wave loom, which I dug out and warped after a trip to a lace day sponsored by the local lace group, where I came home with a little baggie of about $200 worth of lacemaking threads, some hand dyed. I immediately set to work warping my Wave loom, called “Quark” and am really happy with the result. Warping was a challenge, but weaving is a breeze.

The rest are a large assortment of inkle looms, there are four Schact Inkle looms, seven Inklettes from Ashford, and a Beka, named “Beka“, which doesn’t have a warp at the moment, but I recently finished off a long warp for an Anni Albers’ Necklace project with my guild around the holidays.

I loved the Inklettes for their portability. I could fly somewhere to teach, and pack a half dozen of them in my large roller bag and be able to have a technique in progress to demonstrate with. I’d love to clear them, since I don’t do that anymore, but all of the techniques are part of my Advanced Inkle Weaving class (which I can do remotely), and there is a monograph available that details all of the techniques and how to do them. You can purchase the download in my eStore here.

“Bryce” has a beginning sampler with plain weave and Baltic Pick-up. I keep it as a “Learn to Weave” loom for inkle weaving.

“Adira” has a sampler featuring a complementary warp, light and dark, specifically for pebble weave. Warp yarns are Tencel.

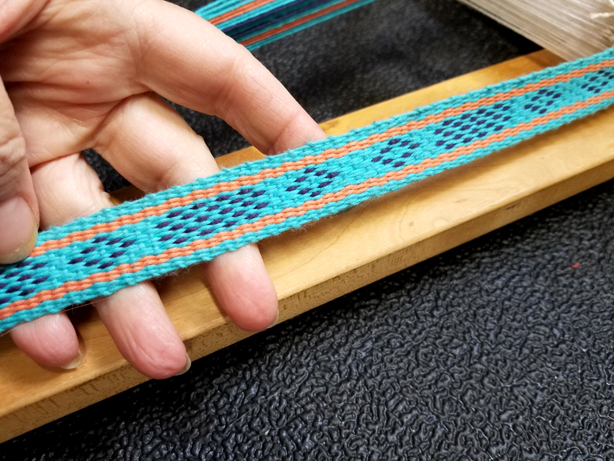

“Stamets” is set up for Paired Pebbles, and I just keep repeating this small motif, for demo purposes, but it would be nice to have a finished band, maybe across the top of a small zippered bag! The threads are 12 wt. cotton..

“Tilly” has a sampler on it, for teaching purposes, supplemental warp and baltic pick-up.

“Nelson” is set up for a supplemental weft project, trim for a jacket, like the Chanel style.

One of my favorite patterns, from Ann Dixon’s book of Inkle Weave patterns, is something called Runic. It is free form weaving, you make it up as you go along, and I set this loom named “Owo” years ago, with hand dyed silk yarns from Treenway Silks. I need to finish it.

And “Detmer” is threaded for 3 shaft Turned Krokbragd, done on an inkle loom, which is a very cool thing. This is also Tencel.

That leaves the four Schacht Inkle Looms. “Rios” is a sampler, also for teaching purposes, threaded in a complementary warp, light and dark.

“Raffi” is another of my Learn to Weave looms, set up for simple Baltic Pick-up, or just plain weave.

“Jurati” is also set up as a beginning loom, with plain weave and Baltic Pick-up options.

And finally, yes there really is an end, is “Elnor“. I set this up in 2021, when I downloaded Annie MacHale’s newest book for Three-Color Pickup for Inkle Weavers. It took me a while to master the pattern, and of course I don’t remember what I did, so I’ll have to go back and figure it all out all over again, but that’s the point of all these looms, so I’ll keep figuring it out and one day have all these structures in my head ready to explain intelligently as needed.

My guild mate, who comes on Tuesdays to just play with all of my Structos, suggested a huge accordion file to store the paperwork for each of the named looms. The one she brought me wasn’t big enough with 30 something files, so I bought a second one and taped them together. Now to get paperwork for some of these looms from my daughter!

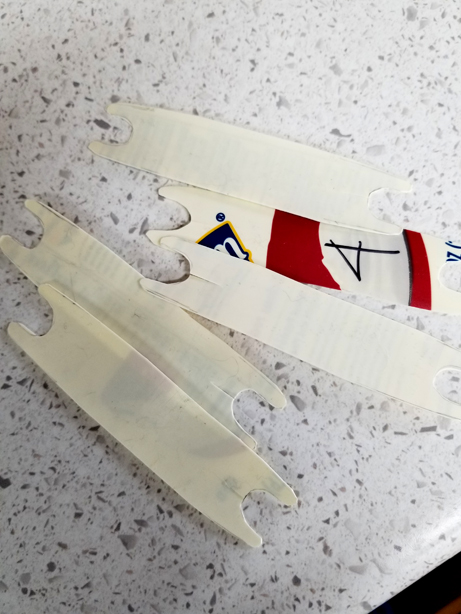

So you might wonder how I have shuttles for all of these looms, especially the Structos, which I talked about in the last post. I have a huge number of shuttles, stick and boat, but needed way more, and guild mates jumped to the task. Some I cut myself, from quart yogurt containers. I’ve also used take out food containers. The flat rectangular kind.

My guild friend who comes on Tuesdays went home and cut me a bunch from her cat litter tubs.

My other guild friend went a little crazy with her GlowForge and cut me a whole bunch of gorgeous stick shuttles and programmed in a sweet signature on some of them. In exchange I paid her guild dues. Small price to pay!

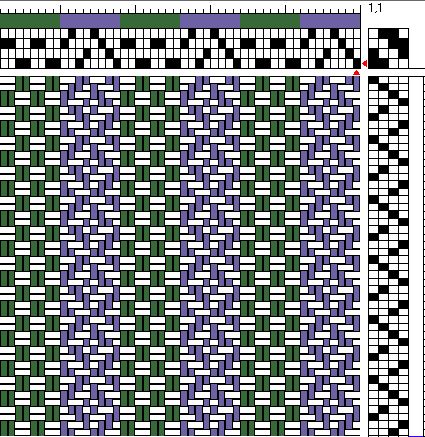

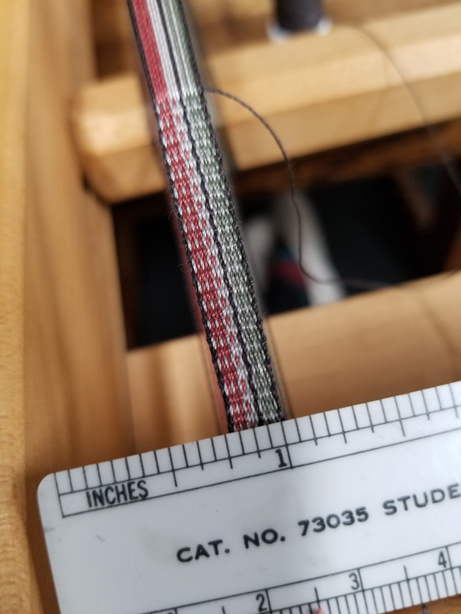

I mentioned in the last post, that I had already cleared one of the floor looms. That was a 4-shaft commission for another guild mate, for a friend of hers dining table. It needed to be 84″ long, and she wanted me to weave it in whatever structure I loved the most. The colors had to match the friend’s decor. My favorite structure is the one where I combine all sorts of different structures lengthwise in the same cloth. I have previously mentioned I documented this concept heavily in the Heddlecraft issue #38 I wrote on the subject. But I usually work with 8 shafts. I only had a 4-shaft loom available. So I reread my article, and revisited one of the 4-shaft drafts I included, from Oelsner’s Handbook of Weaves, and expanded it to include a straight draw twill, basket weave, and a broken twill. Using color and weave effects, I am so freakin’ proud of this cloth and its complexity, on only four shafts. So here is the runner on my own table, I can’t wait for photos from the client’s friend’s table.

And here is a close-up of the fabric. The draft and details are available in my eShop as a $2.99 download here.

I’m heading out next week for a very long overdue vacation. I haven’t been on a plane since March of 2020 when I barely made it home from the west coast before the world shut down from Covid. My daughter and I will be on a plane for 15 hours to Japan, where we will meet up with a tour sponsored by Tom Knisely and his daughter Sara Bixler, from Red Stone Glen. We will make a circular tour of the northern part of Japan, stopping at many textile centers for lots of hands-on experience and inspiration. Oddly enough, I’m trying to figure out what to pack, not clothing or toiletries or electronics, but what yarn I should bring. Because no good textile artist goes anywhere without a project. Socks to start, I ordered some lovely yarn from Webs, hope it comes in time.

If you do order from my shop, digital products will be available immediately since I’m not involved. Don’t forget to check your spam for the email with the link. If you order products that I have to ship, please be patient while I’m busy in Japan. I’ll resume shipping after the 18th.

So dear readers, until I return, I’ve given you things to inspire you, and keep you busy while I’m gone. My son will stay here off and on and check that all is well with the garden and the ponds. And my handyman will come around as well. I would be lying if I said I wasn’t feeling any anxiety about leaving and going so far away for so long. I’ve been home for too long, so this is an important trip for me to regain my traveling feet. (And no, I’m not planning to resume teaching on the road!)

Stay tuned, there will be lots to tell when I get back…