With apologies to Hilary Mantel…

I wish I could have taken a picture of me following a County College of Morris Dodge Caravan heading west on Rt. 10, loaded with 20 dress forms, all stacked like bodies, on the way to the college gallery with the second load for the exhibition. It was pretty hilarious.

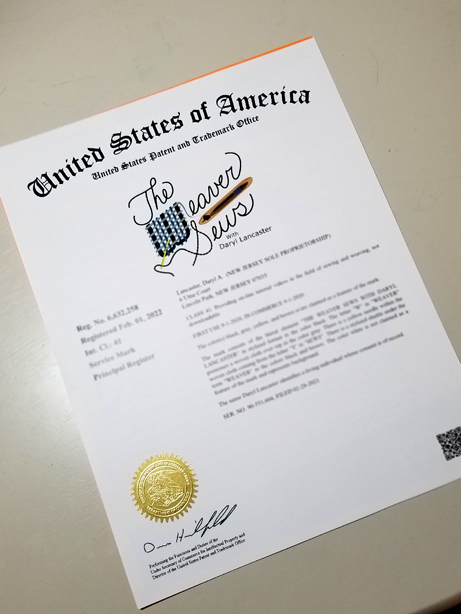

This has been one of the most intense but awesome assignments of my life, to organize a retrospective of my work, and all the moving piece parts, assign labels, write 15 artist statements for the 15 categories of work, some 90 pieces, including wall/art pieces. Enormous.

My best friend in High School said to me on Facebook, “I knew you when…” and “Is this like getting an Oscar?” Wow. What a lovely thing to say. I wouldn’t know, since I’ve never gotten an Oscar and have never done anything to deserve an Oscar, but this retrospective is pretty important to me. I think of it more like a lifetime achievement award. Slow and steady. Because one of the sponsors of the show is Morris County Teen Arts, there was a request to go back as far as I could with work to tell the complete story. So there is a macramé vest I did in 1972. I’m still proud of that piece. I was 17 years old. (And Macramé was all the rage.)

So the last couple of weeks, I’ve done nothing but dress bodies, and store bodies in my guest rooms. The forms I purchased through Amazon were really inexpensive. About $21 each. But… each form costs $25 to ship via Fedex, and the hip measurement of each form was only 33 1/2″. I do not know of a single adult human being with a 33 1/2″ hip. I don’t know who they were designed to fit. Maybe that’s why they were so cheap. So I invested in a few rolls of large bubble wrap, and armed with a tape gun, and a box of shoulder pads I found in the attic from my production days, I bubbled up some 41 dress forms to fit my garments.

All the forms were stored in my corner guest room. I also invested in something like two dozen shirt forms, for the smaller less important pieces that were necessary for the stories. The gallery director came up with a 40 form limit for the existing gallery floor space, and so I needed to also fill the walls.

On Tuesday, I moved everything to the living room to wait for the van. The dogs were initially curious but ultimately bored, nothing I do is of much interest to them. Unless food is involved… That was my workout for the month. I moved probably 40 pieces down a couple flights of stairs, one at a time.

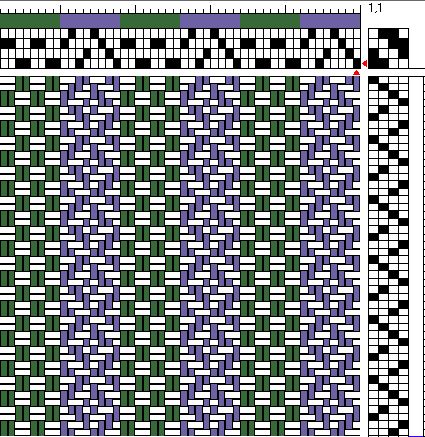

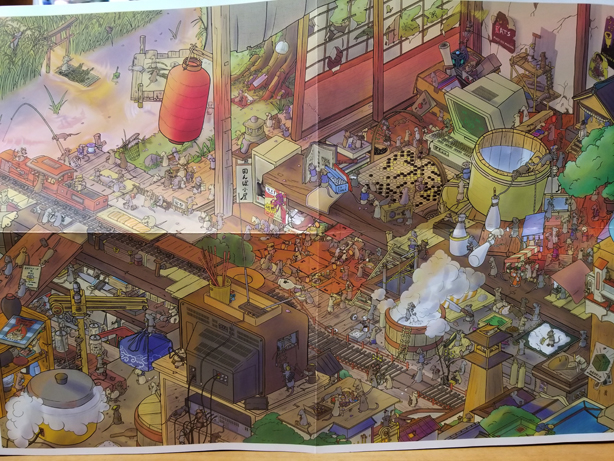

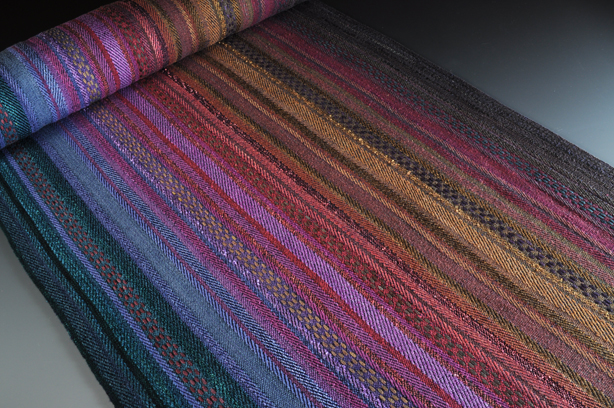

And so everything for the show is now at the gallery. Except the demonstration loom. I designed a 4-shaft fabric, that sort of looks like my 8-shaft fabric, (a variation on my Custom Runner draft in my eShop) on a 25″ floor loom. I started with a poster from one of my Magic Puzzles. This one is called Sunny City. It was sort of sepia-toned and nostalgic. All the yarns are hand-dyed with fiber-reactive dyes.

I got the loom set up in record time. 5 yards beamed.

And I played around with wefts, struggling to decide if I wanted to focus more on the soft palette of vintage looking colors, or showcase the interesting combination of structures which would require a darker warp. In the end I settled on a mid-grey Alpaca/Silk, from WEBS, but I didn’t have enough on the cone for the 4 1/2 yards I would ultimately be weaving. I went to the WEBS site and not only did they still have the yarn, but it was on sale! Score! There is a second cone coming soon. (But I won’t be weaving this off until the fall. The loom will be at the college until the end of the summer.)

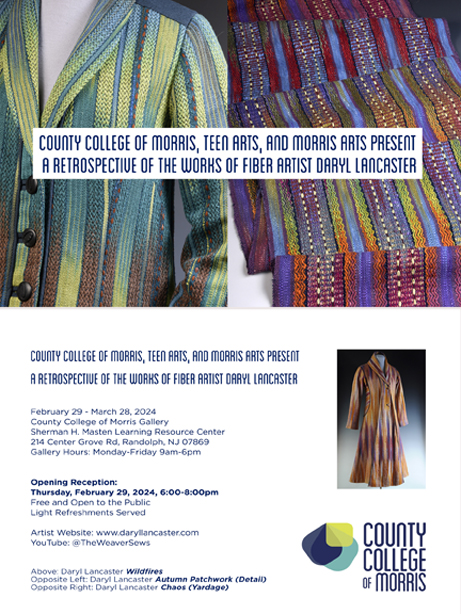

Here is the flier for the show, or rather both halves of the postcard. The show technically ends the end of March, moves to a smaller gallery (just the bodies) and everything else goes into storage while the college puts on its students’ final show. Everything gets remounted the beginning of May, there is another opening, and I give the keynote address for the Morris County Teen Arts Festival. The show will remain in the Main Gallery through the summer. Apparently CCM is redoing its website, so if you Google the gallery, the information is from last October and that won’t be helpful for this show.

We recorded a 12 minute video on ‘how to weave’, and there will be three Structo/Leclerc Sample Looms there for gallery patrons to try. I’ll swap them out each week to freshen, re-warp, etc. I gave a number of my teaching Structos to one of my guild mates who will be taking over the Learn-to-Weave program for my guild, so I needed to clear one of the 4-shaft looms I had set up previously with some random structure. I chose the Leclerc Sample Loom which had a linen warp and wove off the couple yard huck lace sampler. I still had linen on the spools so I figured, this should be easy, I picked one of the designs, and started to weave off the rest of the spools. This was a couple months ago. I’m still weaving. I’ve determined this loom is magical and that it is a warp that will never end. I know a pre-warped Structo spool, back in the day, could hold 20 yards of 20/2 cotton, and this linen is a similar weight. Dear Lord… The spools came to me with the loom, a hand me down from my late mother-in-law. I had no idea how much linen was still left, but how bad could it be? Bad…

I weave an hour or so a day, and still I look back there and it looks the same. I keep hoping I’ll start to see the end soon. I need this loom. Five of the six sample looms are ready to go. I have a five yard carpet warp waiting. Sigh…

So that’s a wrap up of Daryl’s Greatest Adventure, a 40 years look back over an amazing body of work, which isn’t even half of what I’ve done, because there is a ton that has been sold and I didn’t even count the hundreds of garments I sold in my 10 years of craft fairs. I promise to take pictures, and my daughter, who is currently on a Star Trek cruise to the Caribbean, promised to film a documentary when she gets back.

My only real problem now, is I have nothing to wear to the opening, since everything I have will be on exhibit… Hmmmm…..

And I should mention that today, in spite of everything else that is happening in my life, is the 22 year anniversary of my breast cancer diagnosis. 2/22/2002. I will never forget this date. And so it is fitting that I’m mounting a retrospective of what I’ve accomplished in the years since that diagnosis, and there have been many of them. I wish my late husband could have been here to see this accomplishment. I was one of the lucky ones to have lived through a cancer diagnosis…

Stay tuned…