My friend came to visit this afternoon. She said, “You haven’t posted in a while, I keep checking… I miss your posts…” My friend isn’t a weaver, has no sewing skills. We are musicians together, and raised our kids together, but she loves reading my posts. Who knew?… So, I promised her I’d sit down tonight and post one. And I was shocked at how behind I was on all the interesting goings on in my neck of the woods.

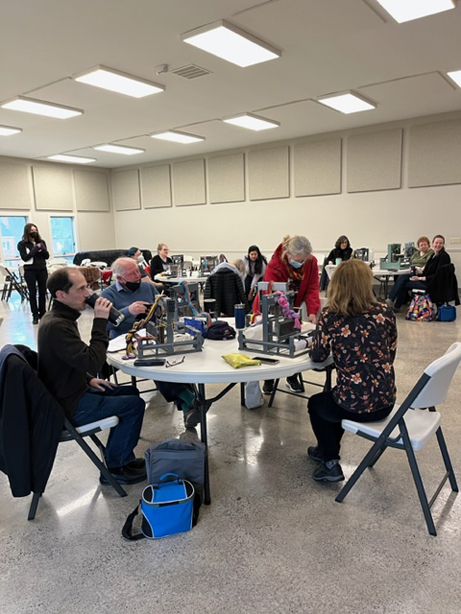

I made it through the holidays. They were quiet and somewhat challenging, but this is January, and a fresh start, and unlike this time last year, my shoulder is mostly healed and I’m carrying on. But January, after a couple of years break for Covid, means it is time to buckle down and do the final preparation for the Learn To Weave Class that I teach for my weaving guild, the Jockey Hollow Weavers. I spent the last few months rehabbing a number of additional small Structo looms I had acquired, and though the looms were ready to go, I had to wind 16 warps (I wind two at a time, cross at both ends and cut in half), and print all the handouts, and of course packing and loading the car. All on account of I had agreed to do this. I always ask myself why, until I’m actually doing it and I realize why I agreed to it and how much I love it.

We ended up with 14 students after a number of last minute cancellations, mostly from people not feeling well and terrified of spreading something nasty to fellow weavers. In the past no one would have thought twice about coming with a little cold or cough. But I appreciated the caution, and to my knowledge everyone from the class was and still is healthy.

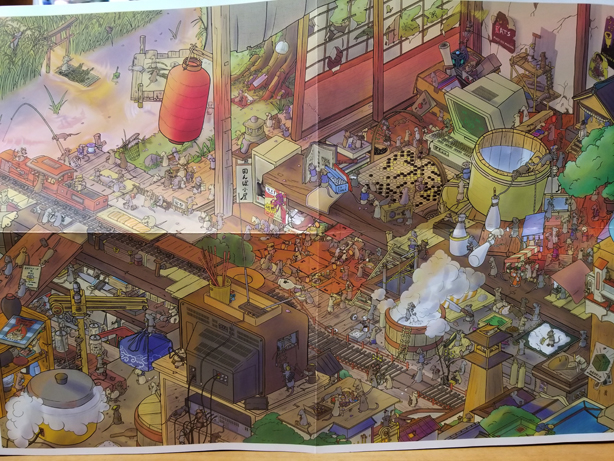

So I give them each a small 4 shaft loom for the day. Most have no previous weaving experience, though a few are rigid heddle weavers, wondering what the shaft experience is all about. I prewind a warp from 8/4 cotton, in two colors, with a striped section in between, and they sley the reed, thread the loom according to the draft I give them, which has a point threading and straight draw, learn to read a draft, and weave off a small sampler of all the cool structures you can do on that point threading and straight draw. In one day. They work hard, and learn a lot.

Usually they either kindly thank me for opening their eyes to the work involved in weaving, or they want to jump right down that rabbit hole and immediately join the guild and borrow loaner equipment and become our newest weavers. I already have three who have since joined the guild. And one discovered a two shaft structo loom hiding in her basement purchased from some consignment shop years ago. It is only 2 shaft but she is on her way. These were her samples.

All on account of I did something really really dumb, something I’ve never done in 35 years of teaching, I double booked the day. Apparently back in May, I agreed to pencil in a date to give a lecture for a guild in Oregon. The same day as the Learn to Weave class. Which wasn’t officially in my calendar at the time. I didn’t hear back from the guild until the end of December with final plans. That’s not unusual, but what was highly unusual was there was no record of the lecture in my calendar. I never ever make that mistake. They couldn’t switch speakers from another month, and I’m too professional to just say, “sorry…”, so my daughter and I decided to actually film a video on the topic of What to Do with Leftovers, which was what the guild had asked me to lecture on. I scripted it, used the slides from the original presentation, and we created a YouTube video, about 48 minutes long, which I offered to the guild for free as compensation. I admitted to them they were basically doing a beta trial for me, so I didn’t feel like I wasn’t benefiting from the experience myself.

There were some technical challenges streaming the video, my daughter worked with them to try to iron out any issues. This was a guild who was not only showing the video to the in person meeting, but to those out in Zoom Land who were tuning in. That in itself presented challenges. I was on pins and needles all afternoon during the Learn to Weave class, hoping we wouldn’t get a call that they couldn’t get it to work, or something technical went wrong and they didn’t have a program. In the end, it all worked well. I heard they loved it, there was laughter all through the video, something about my deadpan comedic expressions (all my daughter’s clever editing, I can assure you) and applause at the end. They told me it was one of their best meetings. The palpable relief at the end of a successful Learn to Weave class and a successful guild lecture happening at the same time, was incredible. All on account of I screwed up.

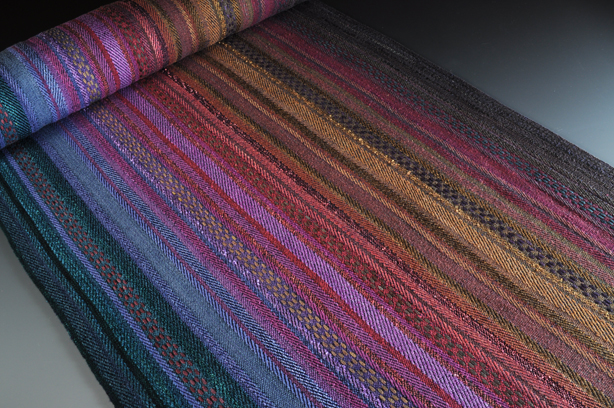

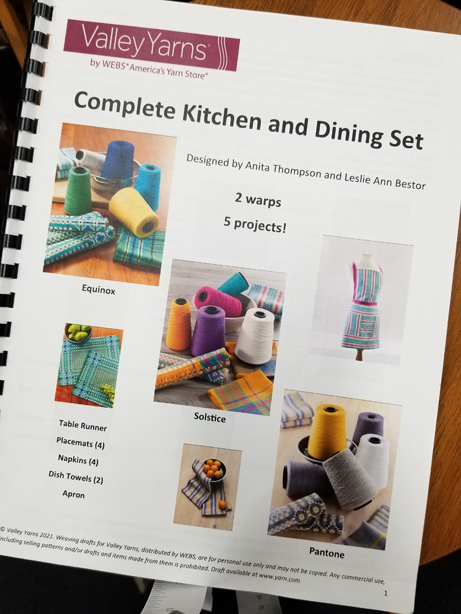

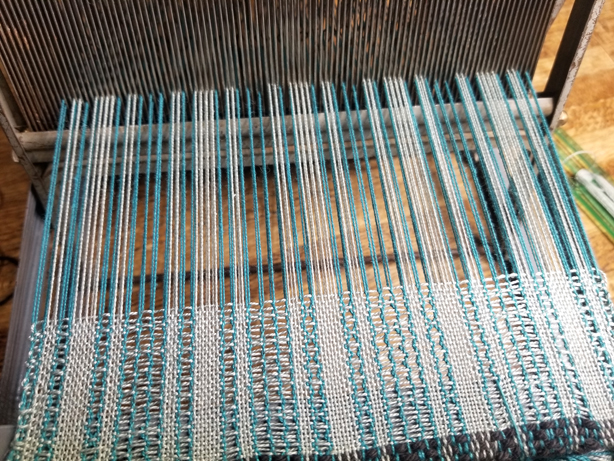

Last year I saw this lovely project download on Webs (www.yarn.com) that had kitchen and dining room textiles, in three color ways. The structure for the striking mats and runner was Summer and Winter on 6 shafts. I bought the download and printed it. It called for 8/2 cotton, which I had a tonnage of…

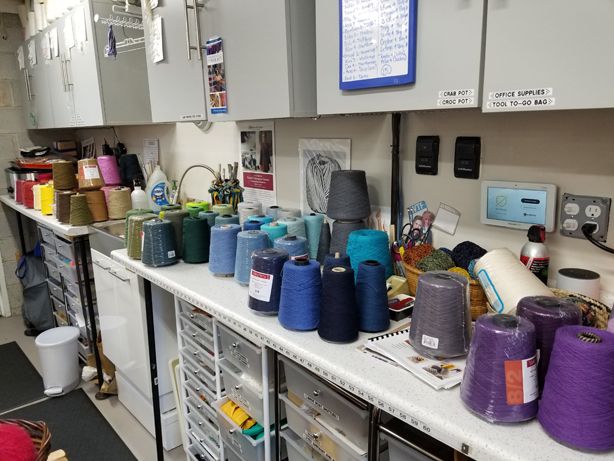

It was all on account of I couldn’t see what I actually had because the cones were all stacked to the ceiling on top of the wall units four deep. So I had my daughter climb up and pass me down all the cones, which I lined up on the dye sink counter so I could start keeping a log of what I had, where it was from and how much of each color I had.

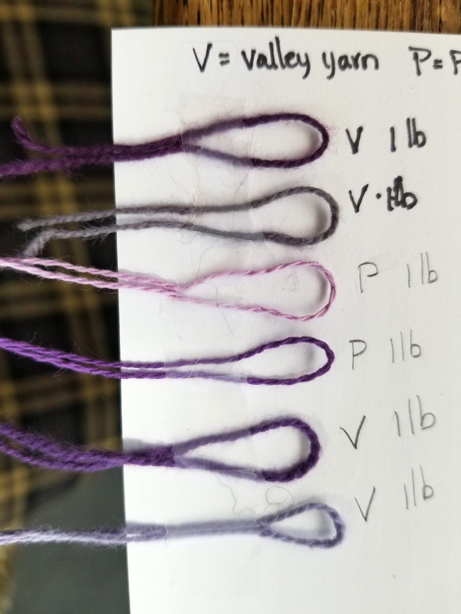

We eventually got all the yarn labeled, catalogued on little cards, and stacked back up, but I held back yarn I thought would work for the mats. I didn’t have a key color for each of the colorway choices, but I wasn’t about to order more yarn for a missing color, so I got creative with what I had. I substituted out the green for a more celadon color, I didn’t really like the green anyway (I did have that green, just not enough).

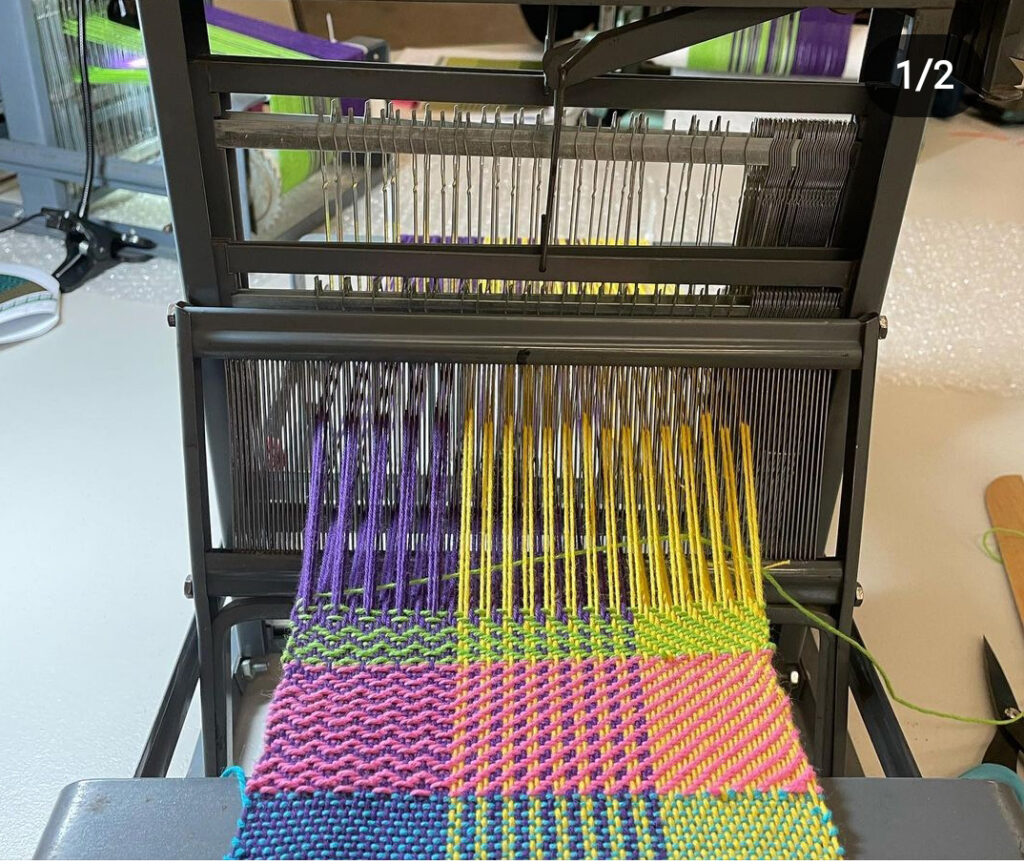

And I spent the day Wednesday, winding the 8 yard warp, sleying the reed, threading the loom, and beaming the yardage. I was weaving by Wednesday night. It is nice to know what’s on your shelf!

Meanwhile, on account of I was giving a remote lecture to another guild, also on the west coast, late last night, on the topic of Doup Leno, I decided to try to see if I could actually do that technique on one of my four shaft Structos. And so, I spent the early part of the week figuring that out, and was really pleased that not only did it work, but I really liked the fine lacey cloth from the 10/2 cotton, and I could use it as a second live demo during the lecture last night. I’m still experimenting with the cell height, but that’s expected.

And earlier in the month, or maybe it was during Christmas week when nothing happens, and there is always fun to be had in my studio, I set up an eight shaft Structo with a honeycomb structure, from Malin Selander’s book, Weave a Weave. I am having a blast with this one. All on account of I have these 30 Structo looms…

I’m sorry January is nearly over. I like this month, it is cold and nothing happens in the garden and I can hunker down and really play. Once the Learn to Weave class is over.

Stay tuned for more adventures on account of I have a bunch of looms that are naked and not happy with me, and of course, I have to update the prospectus now, for the What to Do with Leftovers lecture that has a viewing option of watching my video instead of me live on Zoom, for a lot less money! Seems like each time I do anything digital, there are 57 things that then have to be updated…

Happy New Year!