So now it is 2024. All of those things that I didn’t have to think about, because they were so next year, well they are closing in upon me! Lots of remote lectures and teaching. Seems guilds, including mine, are taking advantage of knowledge gained via Zoom, and booking their dark winter guild meetings, with potential hazardous weather, with things that can be done remotely. I have already given a couple of lectures, and have a number of upcoming workshops to teach, all remotely, but alas, prepping for them, even though they are remote, is still at times onerous. Getting the contracts out, the correspondence, which guild wants what, shipping kits if necessary, letters to students, materials lists, and PDF’s of the presentation… Still all that makes my head spin and I’m trying to keep everything straight. There is always that fear, and I had it when I taught on the road, that I’ll show up (even via Zoom) and have the wrong presentation and materials! Fortunately with Zoom, I have other lectures loaded into the laptop, so it is easier to switch. It only happened once in my career, and I had the correct topic, but grabbed the wrong bag of samples. Still…

I briefly mentioned a few blog posts ago, that the local community college is planning a large installation of my work in their gallery, and I have more than 60 garments, plus all of the artwork. Since I wear many of the garments that will be displayed, each needs to be cleaned, de-fuzzed, pressed, bagged, and a handling swatch included. Mostly I’m hand washing everything, I’m not sending 60 garments to the dry cleaner, and they don’t always clean what I want and how I want. So that means that I have to start now, working on a couple a day. I bought a good fabric shaver from Wawak.com, which helps take pills and fuzz off surfaces. Works like a dream. I have to dig through bags of scraps to find a piece for each garment to be used as a handling piece. I have to make the occasional repair. And garments I opened up for viewing in my videos have to be stitched back together. It is all a wonderful challenge. But it will take time and this isn’t something I can do at the last minute. The end of February will be here before you know it.

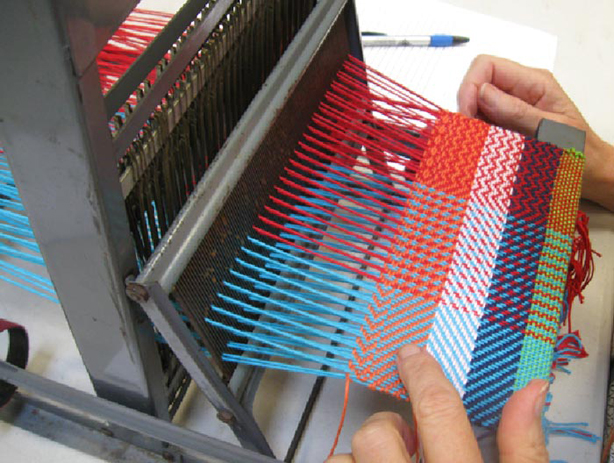

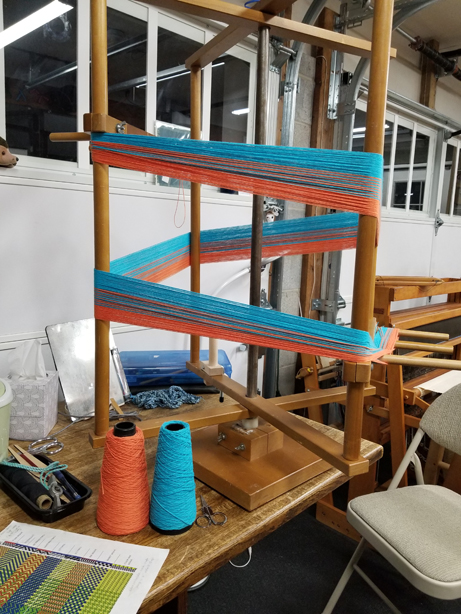

Next Weekend is my guild’s Learn to Weave class. I bring 15 Structo looms and pre-wound warps and I check the weather every hour starting January 1st to see if weather will cause the class to be postponed. It is always a nail biter. I had a guild friend come and help me wind warps. We make a cross at both ends and then fold the warp in half and cut, so making two warps for our efforts. The class is full, with a waiting list, and I’ll get the final letter out to each student probably tomorrow. It looks like the weather will be warm and rainy.

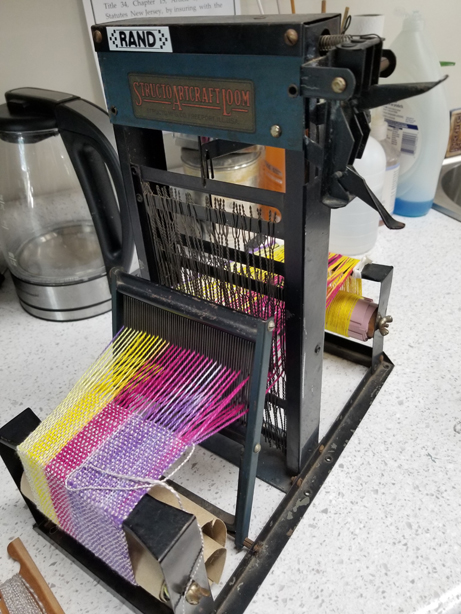

Meanwhile, that guild friend, is planning on long term borrowing 12 of my Structo looms to do some teaching of her own, with the goal of bringing weaving to underserved communities. It is a pleasure working with her, but if I give her 12 of my Structo looms, and the gallery exhibit at the college is planning a hands on component, I need some additional looms for that purpose. I have a total of 30 Structo and Leclerc Sample Looms, and a bunch are 8 shaft. I had set up the fifteen not reserved for “Learn to Weave” with various structures which I’ve enjoyed over the past year and a half, but I need to clear a few for our joint needs this year. Clearing a Structo table loom with 5-6 yards of fine warp… Well I’ll be honest, is not my favorite task.

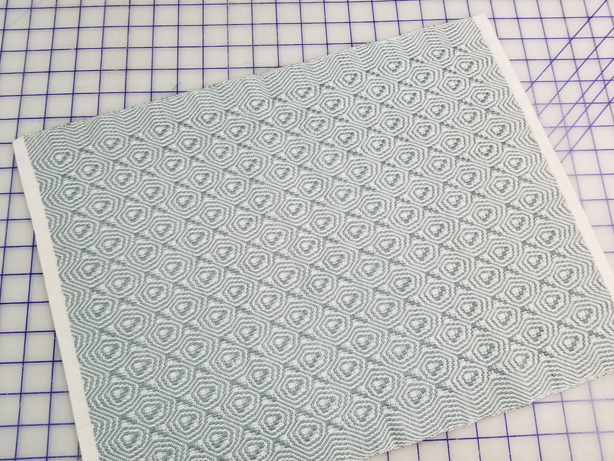

I could just cut off what’s on the loom and call it a day. And that might happen. But I started with the easiest one, or so I thought, and wove off the huck sampler I had warped, maybe a year ago. The sampler is from the Weaver’s Magazine “Best of Huck”.

The linen warp, came to me pre-wound on spools when my late Mother-in-law gifted me the Leclerc Sample loom probably 25 years ago. I believe the linen spools were original, so I have no idea how old they are. The linen is in good shape, but this is the warp that never ends. I have no idea how much is on them.

I picked my favorite part of the sampler and just started to weave. I have no idea how much I’ve woven and I have no idea how much is left. I just keep weaving…

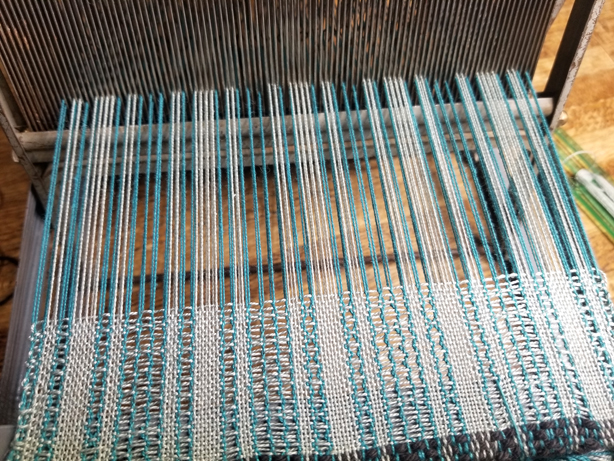

The next loom I wanted to clear was another of the Leclerc Sample looms (I have 5) which had a double weave sampler, based on one from Jennifer Moore’s book. I threaded it in a different set up than she suggests, because some weaving buddies and I were embarking on a study group, and I found it tedious to have to translate each part of the sampler into a different treadling, or in this case a lift plan. I managed to do a few of the sample drafts, and a section of pick up. This pick up had quilted stuffing in it, and I didn’t like the lines I was getting, so I dropped the stuffing half way through and liked the results better.

So I brought the table loom over to one of my many floor looms, and decided to transfer the warp, once the sample was cut off, which was sort of hilarious. With just a few hours of work yesterday, everything is now on the floor loom, with treadles, and threaded in Jennifer Moore’s suggested threading. Life is good.

I blew through the first exercise in short order. Ok, I’ll admit, table looms are laborious. Necessary yes, but I didn’t think I’d ever get this woven off on the table loom.

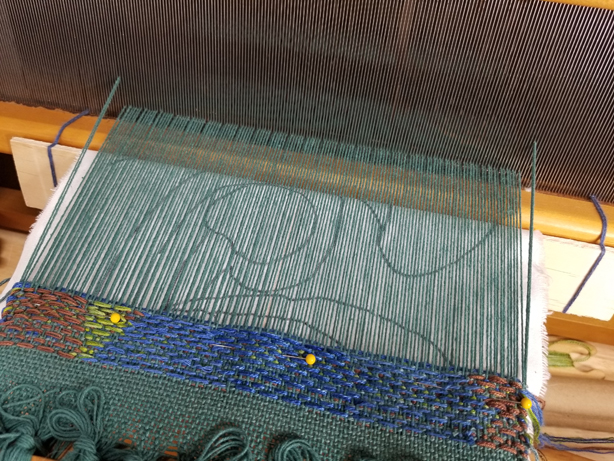

I wove my little heart out between Christmas and New Year’s, and suddenly the knots in my 10 yard warp were coming up over the back beam.

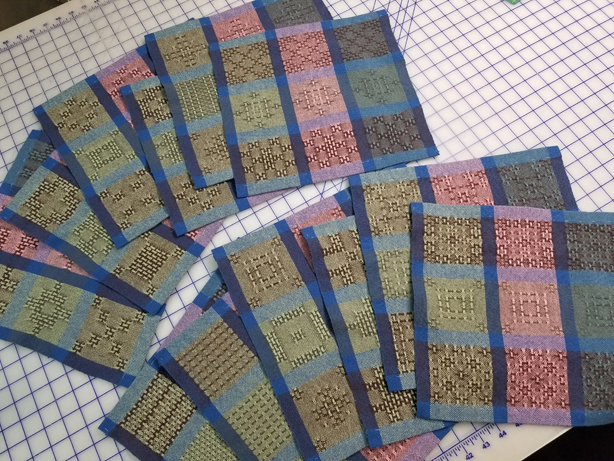

The towels are all hemmed, and I’ve distributed those to whom I had promised a towel. This is a variation on my custom runner draft, a combination of structures, and some color and weave effects on 4-shafts. I’m pretty impressed with this, and I already have plans to put on another run as I have a ridiculous amount of 8/2 cotton on the shelves…

The coming year will be particularly challenging for me, as my son is about to deploy to a part of the world that is tough for me to imagine. My plan is to stay so busy I won’t have time to worry, but I’m a military mom and I understand my role and that this is what my son signed on for, and he is good at what he does. God Speed Eric…

So I’ve booked myself, on top of everything else, 8 classes at Peters Valley, some are remote, but I want to learn new things, and stay inspired. And I’m hoping all the new landscaping plans, involving native plants, will be underway in just a few short months. I look forward to lots of time on my knees in the garden getting muddy.

I wish all of you a gentle year, full of inspiration and creativity, surrounded by those you love and lots of fibery stuff.

Stay tuned…