Back in 2013 I wrote a post with the same title. I reread the post in prep for using the title again, and yeah, this one should be titled, “Hold my beer…”

As the story went, “back in my college days, I befriended a nun who worked on campus. We all called her Sister Fran. She had an old station wagon. She use to drive students around to wherever they needed to go off campus, and we’d pile into the back of the wagon and head off into the town. When Sister Fran would come to a rather busy intersection, especially one without a light, she would barrel on through shouting , “Fran, no guts no glory!” I learned a lot about life through that mantra, and learned a lot about driving in NJ.”

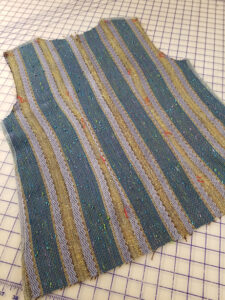

I recalled that mantra this past couple of weeks as I embarked on a rather risky use of fabric from my box of yarn that Silk City Fibers encouraged me to play with. This fabric featured a very muted orange Cotton Bambu, one of their newer yarns, heavier than I would normally use in any weaving, and I combined it with some of their old standby’s, and came up with this…

The draft and notes are available for free in my shop, since they gave me the yarn, I feel obligated to share anything I come up with for free. Click here.

As I’m weaving this fabric, the vision of a leopard skin coat, that has been living in my closet for many many years, I’ve lost count, kept swimming into my head. At one point I pulled out the coat and looked at it with the fabric still on the loom. This is one of those times when “No Guts No Glory” came into my head. I knew I wasn’t going to have much fabric, net maybe 3 yards if I was lucky, I only have what yarn Silk City Fibers gives me, so a vest made sense. What if I lined the vest with the fur? It could be either really really cool, or really really awful. I voted for “let’s find out…”

So I finished the fabric pictured above, and brought the coat to the sewing studio in the basement. The lining had been pulled from the coat a long time ago, I seem to remember it was disintegrating. Maybe not, maybe I was just curious. I also remember loaning it at one point to the HS for a costume for a production of Little Shop of Horrors.

If you have never been inside a vintage coat, it is really something to behold. All those skins are strategically stitched together into an amazing pattern.

Please, no letters. I would never purchase a fur coat now. But many years ago, having used vintage fur in a couple of art pieces, here and here, I have this vague recollection of someone giving me a coat, thinking I might incorporate it into a garment some day. It was a long time ago. The problem is, a number of animals died for this coat, and it is old, out of fashioned, dry rotted in places, and what do you do with something that should probably be tossed but I don’t have the heart. This was once a living breathing thing. So if I can give it yet one more life, I feel like I have maybe brought some good karma into my own life and saved something precious from the landfill.

I started to dismantle the coat, and found in one pocket a name and address. Kris Kolber, if this is your coat, it is being put to good use. The other pocket was full of sunflower seed hulls. I’m not going to comment on that, except to say that at one point, in the old studio, where this coat hung for years, I did have an issue with a couple of mice who secretly hoarded a stash of bird seed in all the yarn cones on my shelves. They apparently made it to the second floor via a baseboard hot water heat pipe…

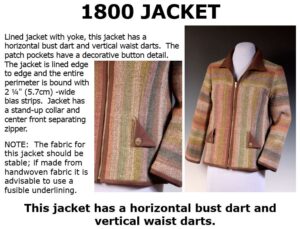

Meanwhile, I didn’t want to put patch pockets on this vest, but I did want pockets. So I designed a welt pocket. The goal is to write the directions for it, so it can be used in my jackets and vests. Please be patient…

I also debated whether to leave the fabric as is, fuse with a fusible underlining, or quilt the fabric. I needed the fabric to support the weight of the fur lining, so I opted for the quilted body, and underlined collar.

Working with old fur coats is a challenge (and no, I’m not looking to acquire anymore), mostly you are trying to salvage areas that are brittle, torn, cut for design purposes, and of course, there will be fur EVERYWHERE!

I’ve spent the last few days in massive handwork, sometimes with a pair of pliers, but I’m completely loving how this is coming out. The real challenge will be the armholes, and I have an idea how to finish them with the fur. Meanwhile, I’ve looked at many button options, and come up with these. I’ll be using Scunci hair ties as the stretch button loops. I think. I won’t really know until I try it.

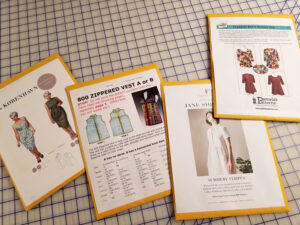

This vest is my 800 vest pattern, without the zipper of course which wouldn’t be practical. You can purchase the pattern here.

MEANWHILE…

I have some really big news here, I feel like I’ve just given birth. Bri, my daughter and I have been quietly filming and editing footage for a YouTube channel, We launched the channel for real, though I should say she launched the channel, because without her, this would never have happened. She has been tirelessly slaving away at the Adobe Premier tutorials online, learning how to edit multi camera and sound footage, and for a novice, I’m really impressed. We call the site “The Weaver Sews“. (And yes, I’ve applied for a trademark)

https://www.youtube.com/channel/UCmz2mYvnteUP11-LvK8-eNg

So I now have a YouTube channel, which will hopefully contain a weekly upload of a short video that pertains to sewing with handwovens. We have shot four videos, two are launched, two are waiting for edits. We write our own close captioning, so it is accurate and sync’d. Please check it out, and if you feel like this is something you will benefit from, please subscribe. It is free. As I add content, you will be notified.

And I gave one of my first remote lectures since the pandemic began last March. It was incredible to be able to turn on my computer in NJ, and give a presentation to a group in the Pacific Northwest, almost on the border with Canada. I know many of these ladies. Last year this time I was on Whidbey Island with many of them doing a private retreat sewing event. Seems like a lifetime ago, now. All the pre planning, monies spent on upgrading my equipment, video, sound, ethernet speed, it all worked in the best way possible. This is a completely viable way of sharing my knowledge without dragging 170 pounds of luggage 3000 miles away. I’m hoping that this can become the new normal in much of my life.

I’ll continue the handwork on the vest tomorrow, and hopefully work out the armhole trim, and start a new week with hope and confidence that all will be well. Because I know deep down that all is not well in the world, but I can only wake up each morning, do what I can with my day, and hope I get to learn something new and share that with someone else.

Stay tuned…