Dearest readers and followers on facebook…

You make me laugh. Oh the uproar when I posted my near completed jacket and mentioned that I wanted to wear it around the house over my pajamas. Best laugh I’ve had in a week. Like handwoven anything can only be used for special occasions. So here’s the thing…

- We are trapped at home in quarantine and I have no plans to leave the house for any reason for the remainder of this year, and probably well into the next.

- I have a bulging wardrobe of handwoven stuff to wear for special occasions. Even culling the early stuff, there are 30 years of gorgeous handwoven garments in there, that I have no place to wear. (And some of them are not fitting me too well either, given that the last nine months has padded my lower half just a bit more than I’d like…)

- Being trapped at home spending my days either working in my office at the computer, like I am now, or in the weaving studio, or the sewing room, or the kitchen, means that comfy flannel pajamas, now that the weather is cold (I keep my house at 64 degrees) are my wardrobe of choice.

- I only dress for Zoom meetings, and trust me there are about 50 options for what to wear.

- My beloved go-to knockaround commercially purchased jacket that I throw on when I get out of bed in the morning, and take off at night, hanging it on the coat tree in my room, is getting worn, old, boring, and it needs to move on.

- I want something cuddly, roomy, with large pockets, and can also hang on the coat rack every night without getting the center back neck bump from the hook.

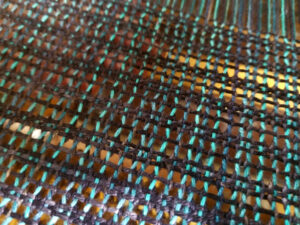

Enter this fabric which recently came off the loom.

I blogged about it in the last post, and there is a link in the last post to the details, what I used as a draft, the warp and the weft, in the last post from when I first put this fabric on the loom almost two years ago. I love the colors, and this fabric I knew would be challenging to lay out. The coloring was formed from the engineered gradient in the Noro Taiyo Lace skeins I was using. Though they were engineered to repeat themselves, when a dreaded knot in the skein would appear, or I had to change skeins, the sequence was thrown off. So I did the best I could…

I had lots of unwanted assistance, trying to lay this out, stretched all across the sewing room floor which is in the basement, and all the way into the utility closet. The cat was very amused…

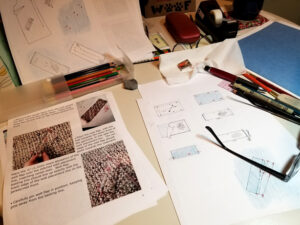

It took two days of moving pieces around to get what I wanted. The fabric wasn’t really wide enough, but fortunately last Friday’s YouTube video shoot was on that very topic, What to do When You Don’t have Enough Fabric. So I shared some of the tips I did in this garment to try to make the most out of what I have. That video should drop next Friday. It is still in edits. (Who am I kidding, she hasn’t started editing yet, she waits until the day before…)

Anyway, I wanted something unfussy, and perhaps crocheted around the perimeter, so I wouldn’t have to fuss with hems, or facings, or bands, whatever. And I wanted big pockets. I pulled my 100 Jacket, chose a larger size than I would normally take, so I’d have roomier sleeves to fit over whatever I was wearing, overlayed the neck from the 800 vest pattern, and extended the fronts 3 inches so they would fall back into a mock collar, but still could overlap to keep my chest warm when I really wanted to snuggle. (It is on my list of topics for my YouTube channel The Weaver Sews, to illustrate how to combine patterns, putting a sleeve on the swing dress, combining patterns for different necklines, etc.)

I got exactly what I wanted, and posted it on facebook last night.

Hahahahahah! The responses were wonderful. I love you all. The outrage that I’d wear this over my pajamas was truly hilarious. Of course it is a beautiful jacket. Of course it should be seen out in the world. But that isn’t realistic right now. I’m not going anywhere. I need to keep safe, healthy and not burden the hospital system because I was stupid. It is worrisome enough that my son, who is an interim general manager at a local Target is exposed every day, so far has tested negative, but is going into the retail season from hell. He is not allowed near the house. NJ lived through hell last April, and we are there again, I’ve lost count of how many have died, almost 17,000 in our state alone. It is as if my whole town got wiped off the map, and half of the next one as well.

And so, I will wrap myself up in a lovely comfy handwoven sweatery coat, and go about my day in comfort. And smile dreaming of a time when I can go out and about and show it off.

So here are some of the observations and details. Because you really don’t know how comfy and snuggly something is until you wear it.

First, since the fabric wasn’t wide enough, I moved the side seams towards the back so I could get a full back from the fabric, and used a crocheted seam finish, overlapping the seam with the fronts. I cover this in the video that will drop next week.

You can clearly see in the photos above where I’m wearing the jacket that the collar points and lower front edges tend to curl inward. There isn’t a facing for support, so I’d expect that. I kept thinking about my late husband’s dress shirts and the little collar stays that would keep points crisp, and I remembered I have a drawer full of zip ties, and there are some really tiny ones in there. I’ve used zip ties as boning in garments that call for that, so why not as collar stays. I slipped a few behind the crocheted edges and I’ll let you know how well they work. Already there is an improvement, time will tell if they hold.

And I dug through my box of inkle bands, and found this lovely narrow black band I wove to help support the sloppy neckline in a sweater I knit. There was enough left to make a loop at the back neck for hanging my jacket at night on the coat tree. That’s the sad very well worn jacket it is replacing on the left of the coat tree.

There are a couple of negatives that I really can’t do much about, one is that the wool (Harrisville Shetland singles from the 80’s) in the warp isn’t the softest. That yarn typically isn’t meant for next to skin. So the jacket is a bit scratchy, but I have a good tolerance for scratchy wool. The good news is it should wash and dry pretty easily, I tossed the original fabric in the washer and dryer twice to get it to full up. That will be important wearing it every day.

And the other negative of course is that I have a bunch of animals, that insist on curling up when ever I sit down, right in my lap, even the ones that weigh 60 pounds. Animal hair sticks to it. It was challenging crocheting around the edges and constantly pulling cat hair out of the yarn as I pulled up loops. And I do vacuum often I can assure you. But the good news is that unlike a fleece jacket, the hair comes off easily with a lint roller, it doesn’t seem to embed itself into the structure. So I’m hopeful my new comfy jacket will prove to be my best friend in the coming months. I want to wear this so much I wear it out!

And speaking of Zoom… I’ve spent many hours on Zoom meetings over the last number of months, and found that knitting wasn’t really for me a great idea, I was making mistakes on the sweater I was knitting in the decorative patterned border. I don’t multi task well. Really.

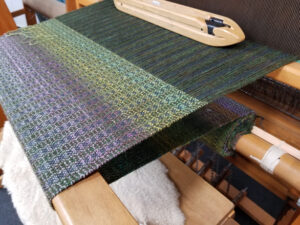

So instead, I started pulling out my bags and baskets of thrums from past warps, most of which were hand dyed yarns, maybe 18-24″ lengths, and started tying them together. I keep the large basket of thrums now under the table where I Zoom. Years ago, one of our beloved guild members, who has since passed, came to a September meeting fresh from a MAFA conference. She had taken a workshop with Tom Knisely, a beloved weaver and teacher who has written a number of books, and one of the techniques she learned was something called Zanshi. It is a Japanese technique for using leftover thrums and yarns so nothing goes to waste. Tom talks about it in his book about Table Linens.

Anyway, the guild member showed her sample from the workshop and I was intrigued. Thrums were tied together with overhand knots and the tails just got woven in. Plain weave, couldn’t be simpler. So I started tying my thrums together. Mindless but productive while I sat through endless meetings. I had a beautiful rayon/cotton discontinued yarn from Silk City Fibers called Marbella, in a greyed brown color called Bison for the warp. I kept the warp narrow so I’d have a bit of color building from the short thrums. I’m loving this. And no, I have no idea what I’m going to do with this fabric. I just like to weave…

Stay safe everyone, celebrate this season with whatever silver linings you can find. Life is getting curiouser and curiouser, feeling more like Alice in Wonderland every day, there is some whacky crap in that story, worth a reread!

Stay tuned…