Grab your coffee, this is going to be a long one!

Wow, what a meeting! Bri and I attended last night’s last Jockey Hollow Weavers’ meeting for the year. We start up again in the fall. We had a lot to accomplish. There was the stash sale, unload what you no longer want. There are a number of retiring members of the group, who are de-acquisitioning and moving to smaller digs in a far away location. Since we have a number of new weavers with paltry stashes, this is always a good thing. Equipment, yarns, books, and back issues of weaving magazines, all find good homes.

Next there was the Pot-Luck. Weavers are always terrific cooks. The food was excellent. The only group who edges out the handweavers for first place in the pot-luck catagory are the lace makers. I’m not sure why this is, but suffice it to say, no one went home hungry!

Of course there was the entertaining show and tell, we had the supplemental warp workshop scarves to show off, and we have a couple of outside of the box creative fiber members who never cease to impress me with their energy and creativity. One member crocheted a spiral rug from plastic grocery bags, and started making curtains by randomly stitching colorful halves of zippers in a haphazard way on a bedsheet. I love show and tell!

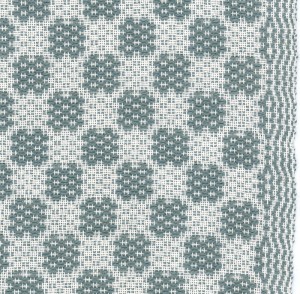

But the highlight was of course, the placemat exchange. It is always a bit disappointing when not everyone finishes on time, and we had one in the group of 16 who dropped out at the last minute, and one of the guild members graciously stepped in to try and weave her set over the summer. But no matter, I’m amazed at how many of the participants were new weavers, including my daughter, who wove a set of overshot placemats, this being only their 3rd or 4th project ever. I’m so excited to see the passion these new weavers throw out into the group, infusing it with youth and creativity, and enthusiasm. It is sad to see older members retiring and moving away, but happily there is some new fresh talent to keep the guild going.

So here are the results. Bri was able to get seven of her eight purple placemats, and they are beautiful. They still need to be washed and hemmed, but she is so excited. The eighth one is as I understand, on the loom as I write.

So here are the results. Bri was able to get seven of her eight purple placemats, and they are beautiful. They still need to be washed and hemmed, but she is so excited. The eighth one is as I understand, on the loom as I write.

I only came home with four, but two more will be exchanged at Monday’s meeting of the Frances Irwin Guild, members of that guild graciously jumped in to give us two groups of 16. One member dropped out at the last minute, and her mats, picked up by another member, and the mats from the other member who wasn’t finished in time, will be delivered in September. What a beautiful collection of overshot patterns!

We had a special guest at the meeting, Alison Giachetti, who is a partner in the new Weavolution, a web gathering place for handweavers, which is scheduled to launch next week. I did some brief alpha testing, and posted some project notes on the site for my Frosted Florals dress, and talked to Alison briefly about moderating a handwoven clothing forum on Weavolution, but that won’t happen immediately. There is a lot of buzz about this, so stay tuned…

Coffee Break! Lots to cover today before I leave for Seattle….

I spent the day yesterday tying up loose ends. I got two pieces of work accepted to the Fiber Celebrated 2009 exhibition, at the Center of Southwest Studies Gallery at Fort Lewis College, Durango, CO. The show opens July 27th and runs through September 20, 2009. So yesterday was the paperwork day, artist statements, technical information, all that had to be back fairly quickly. I struggled with the artist statement. The limit was 70 words. Can you imagine? I can’t say anything in 70 words. 🙂 My average blog posts are over 1000 words. I’m already at 647 words in this blog alone! And I had a lot to say about these two seemingly unrelated pieces of artwork. So, I’ll just use my blog to tell the story that I couldn’t say in 70 words.

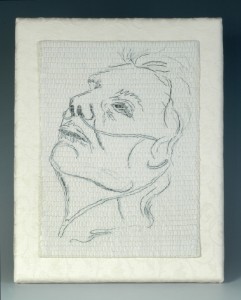

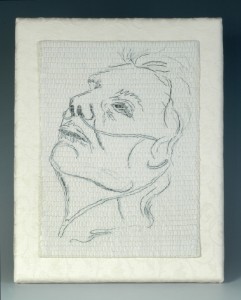

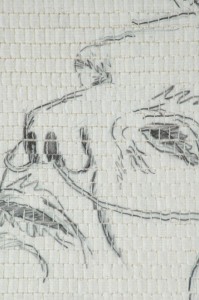

The first piece is one of my small artworks, woven in an inlay style, with strips of silk cut from a digital print on treated fabric. I’ve blogged about this technique in past posts, just search ‘Big Sister’, and you should find the technical stuff. I want to talk more about the inspiration.

The first piece is one of my small artworks, woven in an inlay style, with strips of silk cut from a digital print on treated fabric. I’ve blogged about this technique in past posts, just search ‘Big Sister’, and you should find the technical stuff. I want to talk more about the inspiration.

Many of us have had the privilege of staying with someone, holding their hand, keeping the vigil as we wait for their soul to depart from their old frail, used up body. In 2006, I had the privilege of the long vigil watching and waiting for my mother in law to pass. I adored this woman. She was one of my fiber mentors, and I wrote a piece about our relationship, which you can read, titled Circle of Life. I was so moved by the grace and beauty of a dying woman, the angle of her head on the pillow, eyes half open, yet not seeing. I sketched her profile on a small notebook I keep in my purse. Later I scanned in the sketch, and printed it on silk, cutting the silk apart and reweaving it back together, a metaphor for her life, connecting each row of her profile, until she was whole again. I titled the piece, Watching Death Come.

The second piece, which seems unrelated, (I entered both the nonfunctional 2D and the Wearables catagories), is actually an extension of Watching Death Come. After the death of a loved one, there is the awesome and overwhelming job of disposing of a lifetime of collected treasures, household goods, the cleaning up of one’s life. My mother in law lived to be 99 years old. It was a long life and she had a stash!

The second piece, which seems unrelated, (I entered both the nonfunctional 2D and the Wearables catagories), is actually an extension of Watching Death Come. After the death of a loved one, there is the awesome and overwhelming job of disposing of a lifetime of collected treasures, household goods, the cleaning up of one’s life. My mother in law lived to be 99 years old. It was a long life and she had a stash!

I did my best to merge her fiber stuff with mine, but she was primarily a spinner, and lacemaker, so I have more lace pillows than I know what to do with, as I rarely make lace anymore (can you imagine no time?). And everytime I opened another box with a Romney Fleece inside (her sheep breed of choice as a spinner), I groaned. I do spin, and have two wheels, which I also mentioned in a previous blog, but I’ll never get through all these fleeces and don’t really have the desire to…

Enter felting. Boy is this a great way to use up wool. OK, I know Romney isn’t the sheep breed of choice among the felters, but it was free, and it was my mother in law’s. So, I began to carefully card the washed fleeces into individual gallon ziploc bags, layering the thin carded strips of wool. I wish I had taken photos of this process, it was such a scream felting on my kitchen counter, but alas, I hadn’t started blogging yet, so that didn’t occur to me. I added hot soapy water to each bag and started the felting process, first rubbing, and then rolling, occasionally heating up the wool in the microwave to aide the felting process. Since everything was sealed in a ziploc bag, there was no mess. 🙂

I eventually ended up with something like 18 8″ x 10″ rectangles, in white, of lovely felted Romney. I took my glass 9 X 12 baker, and put each rectangle in one at a time, sprinkling some powdered Cushing Dyes, random colors, I just grabbed a packet and started sprinkling (yes I was using a filtration mask, outside when I did this), added some salt to the felt which was still wet and soapy from the ziploc bag, and covered it in plastic wrap, venting a corner.

I microwaved it in 2 minute increments, and honestly, I can’t remember how long I did this, I just sort of did it by feel, maybe a total of three 2 minute sets, turning the baker each time, until I thought it sufficiently cooked. Once I had this riot of colorful felt rectangles dyed, I cut them apart into random shapes and called Bri into the room, who is a master puzzle maker, future geneticist, who sees patterns where no one else does. I had all the garment sections cut from a fusible knit interfacing, laying out across the table, and let Bri start assembling the pieces in whatever way she liked.

After trimming and fusing the pieces to the backing, I carefully stitched the butted together edges of the cut felt, with a decorative feather stitch on my machine, and where the natural edge of the felt occurred, I used my Janome Expressions needle felting machine to needle felt the overlap.

Then I assembled the jacket, adding a creative buttonhole, and some buttons. I call the piece Stepping Stones. Each component in our life, each experience, builds on the next and paves the way for the next part of our lives. We are all a series of chapters, and no one chapter should be the one that completely defines us. My mother in law was a lot of things to me and the people who loved her. She is missed every day, but her stash lives on!

Finally, I shipped out another one of my pieces to Peters Valley Craft Center, for their summer faculty show. I am scheduled to teach a Fiber Boot Camp, basic fiber techniques, great for those wanting to get into fiber as a medium, learn some of the techniques we all know and love, spinning, felting, kumihimo braiding, tapestry, and inkle loom weaving. This is a great class for art teachers who want to bring fiber to the classroom. I’ve taught it a number of times now, last year I had a full class. I’m not sure if the class is running at this point, the economy has taken its toll on a number of art centers, but the class is suppose to run over the 4th of July weekend, and when it does, I really enjoy being out at the Valley. They offer a number of fiber workshops, in all disciplines, as well as wood, blacksmithing, metals, clay, photography and related topics. I’ve supported the Valley for years, and am always happy to send them a faculty piece for the exhibit.

weaving. This is a great class for art teachers who want to bring fiber to the classroom. I’ve taught it a number of times now, last year I had a full class. I’m not sure if the class is running at this point, the economy has taken its toll on a number of art centers, but the class is suppose to run over the 4th of July weekend, and when it does, I really enjoy being out at the Valley. They offer a number of fiber workshops, in all disciplines, as well as wood, blacksmithing, metals, clay, photography and related topics. I’ve supported the Valley for years, and am always happy to send them a faculty piece for the exhibit.

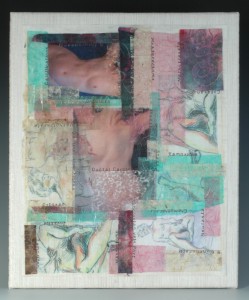

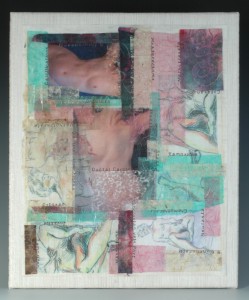

So the piece I sent is a collage titled Surviving Words. This is a very personal piece, I collaged together images printed on silk, with themes of breast cancer, I am a survivor, and that chapter in my life, though behind me, and by no means the one that completely defines who I am, is still an important one and only now, are the themes from that chapter showing up in my work. I glued all the collage components down with gel medium, and once dried, I went back in and stitched all those horrid medical words that defined my life for a year. It is a celebratory piece, colorful, yet feminine, and I hope it is well received in the exhibit.

Whew, thanks for reading this if you made it to the end. I think this is my longest post. I’m off to pack, and hope to blog along the way during my quick mini vacation to Seattle. Happy weaving, sewing, or whatever it is that gets you up in the morning!

Day 1, Seattle: I got up early (I’m still on East Coast time) and made my morning tea. I heard gurgling water and went to investigate. This is Harlow. Robyn has names for all her fish.

Day 1, Seattle: I got up early (I’m still on East Coast time) and made my morning tea. I heard gurgling water and went to investigate. This is Harlow. Robyn has names for all her fish. Robyn lives in a small town on the other side of Puget Sound, and it is necessary to take a ferry into Seattle. This is a lovely skyline, but I will say, I am pretty unimpressed, I live right outside Manhattan, now that’s a skyline. But it was beautiful approaching it on the water, and I enjoyed the lovely long ferry ride where Robyn and I discussed some possible joint creative ventures.

Robyn lives in a small town on the other side of Puget Sound, and it is necessary to take a ferry into Seattle. This is a lovely skyline, but I will say, I am pretty unimpressed, I live right outside Manhattan, now that’s a skyline. But it was beautiful approaching it on the water, and I enjoyed the lovely long ferry ride where Robyn and I discussed some possible joint creative ventures. Our first stop on our excellent adventure was Weaving Works, a very popular knitting/weaving store, I’ve taught there in the past, and Carol Jorstead is an absolute delight.

Our first stop on our excellent adventure was Weaving Works, a very popular knitting/weaving store, I’ve taught there in the past, and Carol Jorstead is an absolute delight.

No, I didn’t buy all the yarn under the glass counter top, just the buttons and the balls of “tapey things”.

No, I didn’t buy all the yarn under the glass counter top, just the buttons and the balls of “tapey things”. Dorothy Day, who is actually an amazing dyer, with a PhD in Chemistry. It is amazing how educated weavers/dyers can be. We had lunch in one of Robyn’s favorite haunts, a middle eastern restaurant called Cedars. We had an appetizer of the house “nan”, a middle eastern flatbread.

Dorothy Day, who is actually an amazing dyer, with a PhD in Chemistry. It is amazing how educated weavers/dyers can be. We had lunch in one of Robyn’s favorite haunts, a middle eastern restaurant called Cedars. We had an appetizer of the house “nan”, a middle eastern flatbread.

Then Robyn took me to the back of the store and the “Ribbon Room”!

Then Robyn took me to the back of the store and the “Ribbon Room”! Here is Susan of “The Ribbon Room”, a back room in Nancy’s Sewing Basket that is just filled to brimming with all sorts of vintage ribbons and flowers and trims.

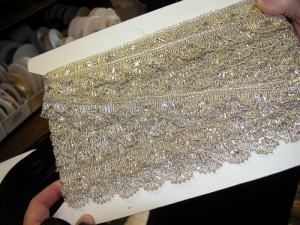

Here is Susan of “The Ribbon Room”, a back room in Nancy’s Sewing Basket that is just filled to brimming with all sorts of vintage ribbons and flowers and trims. On the left, vintage trim made from Aluminum.

On the left, vintage trim made from Aluminum. Gorgeous trays of hand dyed silk ribbons.

Gorgeous trays of hand dyed silk ribbons. And all around the room were these beautiful framed vignettes of Cockades, folded ribbon accents. There were classes available as well.

And all around the room were these beautiful framed vignettes of Cockades, folded ribbon accents. There were classes available as well. We found a Marsha Brady dress.

We found a Marsha Brady dress. And this lovely combo from the 70’s. I remember wearing something like this in High School.

And this lovely combo from the 70’s. I remember wearing something like this in High School. And then we found the rack of shades.

And then we found the rack of shades.