It has been three weeks dear readers since I took my unfortunate fall that left me with a fractured shoulder right before Christmas.

Obviously it has been a painful few weeks, and challenging trying to get appointments, scans, etc. Between the holidays and Covid, I was not able to get what I needed in a timely manner, so I did miss the window of opportunity for surgery. I was on the borderline anyway, surgery might give me more complete range of motion for my shoulder, but the decision was made for me. I just couldn’t line things up fast enough.

Obviously things have been challenging, because I can’t just sit. I know I’ve been firmly told to just rest and heal by well meaning friends, but even after surgeries I’ve had in the past, resting and healing did more harm than good. I can’t sit for too long, because then my back gets out of whack. And my brain, which never stops, gets into lots of trouble if I can’t actually do things…

Once I got the pain under control, I kept thinking about what I could do with only one arm. Turns out a lot. Unfortunately the things I can do aren’t the kinds of things I love to do. Like paperwork, payroll filing, bookkeeping, tax prep. And cleaning. I can run around with a Swiffer duster on a wand with just my right arm. And I have a Dyson Cordless, which easily zooms around with one arm. Unfortunately. So there was no rest or vacation from cleaning, and that’s probably a good thing, because three animals make a mess.

I can also fix puzzles. We always have a puzzle going in a designated corner of the living room. I rotate through probably 100 puzzles that sit on the shelves. With Brianna’s company, we fix a 1000 piece puzzle about every three days.

And I can read, I’m about half way through the latest book in the Outlander series. It is like visiting old friends. And I can watch videos, I signed up for Jane Stafford’s School of Weaving back in October. I’m sure you are wondering why I would sign up for a series of videos on learning to weave. I get asked a lot where the best place is to get good information on how to weave. I’ve heard good things about Jane’s School of Weaving but I can’t recommend what I haven’t actually experienced. I can’t recommend her enough. She is thorough, and although I don’t completely agree with everything she is teaching, I absolutely think it is completely worth the $99 a year fee. Mostly where I work or think differently is because I weave for garments, which is a completely different set of parameters. And I’m also curious about how other teachers use a video medium. And I’m actually learning a few things.

Normally in January I’d be running daily dyepots. I had plenty of new Fiber Reactive Dyes, and lots of new yarn to play with. I thought long and hard about what I could do. I got my daughter to help me pull down all the yarn I had that could be dyed and organize and label it on the cabinets so I knew what I had.

I figured out a way to wind skeins with one arm using my AVL warping wheel.

I have a nice deep waist high stainless steel sink so I could mostly do the dyeing and rinsing with one arm.

I’ve already done two batches, a lovely Blue Grey and Eggplant. Though I could have picked an easier color to dye than Eggplant, lots of rinsing there. I can’t snap the skeins back in alignment, I get Brianna to help with that, and she can reach up to hang them easier than I can.

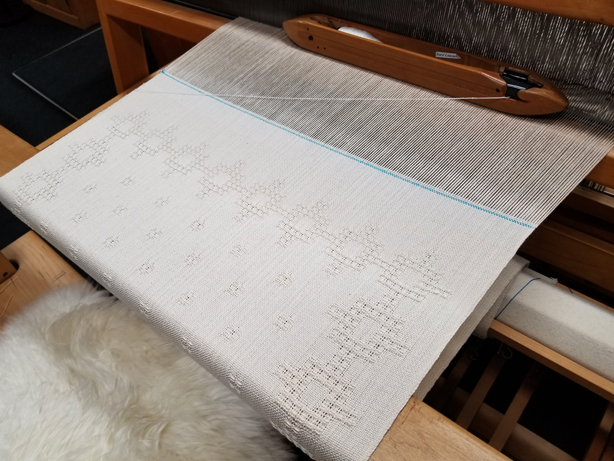

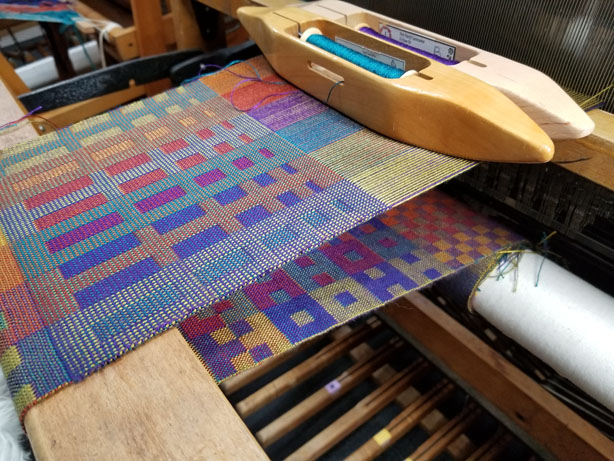

And I can weave on this warp from hell. I put on this 8/2 tencel warp for a Rainbow Double Weave Workshop last October. 48 ends per inch. Two layers simultaneously. So that would be 48 picks per inch. What was I thinking putting on 4 yards? This is the warp that never ends. The workshop was great, and I got to initially explore all the possibilities with the many skeleton tie-ups that the teacher suggested. But I can’t see myself crawling under the loom to try to tie up different combinations. Especially a Macomber. I think all looms need two hands to attach cords, chains or hooks.

So I went with whatever the last sample tie-up was, and I’m just weaving away, 6 inches a day, repeating the same motifs, working through all the bobbins I wound. I can do this with one arm because the shuttle is wider than the warp. I can push it in on one side, let it rest on the race, and pick it up with the same hand on the other side. 4 yards… 48 picks per inch. Sigh…

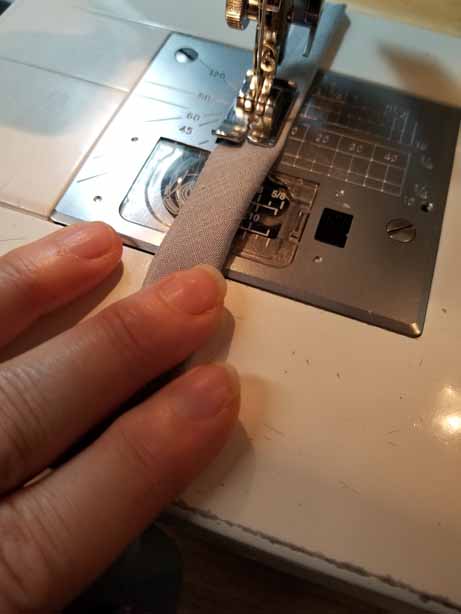

And I figured out how to sew. Sort of. I was working on a four part series for my YouTube Channel The Weaver Sews, on piecing, and the studio was a mess. There were pieces and partial works, and scraps everywhere. The piecing was basically finished, I was working on the binding strips when I fell, so I realized that if I removed the table from around my sewing machine, I could bring it up close and use the fingers from my left hand, peeking out of the sling, to help guide bias strips through the machine. Awkward but doable.

I couldn’t use a rotary cutter, but I could cut the bias by hand, with the scissors. The old fashioned way. Everything just takes longer.

And I can knit. Small things. With my fingers hanging out of the sling. I had purchased some 100% hemp yarn from Lunatic Fringe, Fibra Natura Java, in a few lovely colors. I had heard a lecture on the value of hemp, its antibacterial properties, and I decided to knit up some dishcloths, but I’m actually loving them as body washcloths, they have great exfoliating properties, and I can assure you, showering is challenging so I’m not doing it as often as I’d like and exfoliating is a welcome thing.

I am able to do most things for myself. Except for my hair. I can’t put my hair up in a ponytail or bun. I have to get my daughter to help. Silly I know, but I like wearing my hair up, and out of my face.

A huge thank you to all of you who reached out, privately, on social media, through phone calls and letters and cards. You all make every journey I take so much easier, knowing you walk with me in spirit. This arrived just the other day from the Southern California Handweaving Guild. It just brightened the whole room.

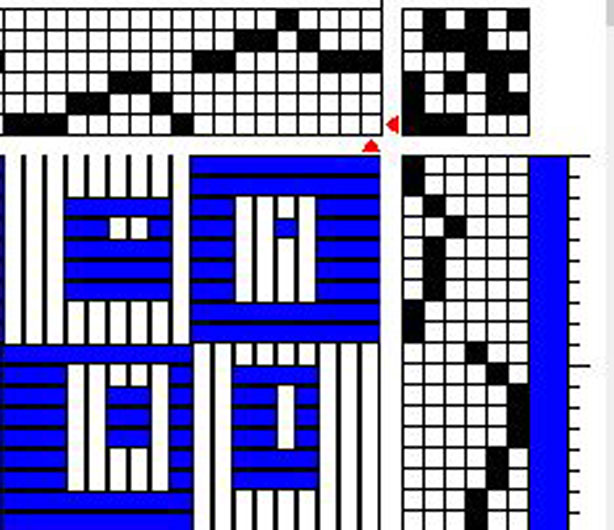

And my wonderful friend Misa came New Year’s Eve to celebrate the coming New Year with a real honest to goodness high tea. She ordered from a wonderful bakery in a nearby city, packed it all up with her favorite tea dishes, and the overshot runner she purchased from a fellow weaver at our guild show and sale last November. It is her favorite thing in the world and she desperately wants placemats to coordinate. I reached out to the weaver who made the runner. She isn’t interested in making placemats. But she pointed me to the Handwoven Magazine article from 2010 and said, “Help yourself!” 20/2 cotton. Really. Another warp from hell. I actually have the yarn on the shelf. And this is a really really good friend. And my shoulder will heal someday and I have plenty of available looms…

And so dear readers I carry on valiantly, resting when I need to and staying busy when I can. I have an article due for Handwoven Magazine at the end of the month, and more videos to shoot, we shot two last week believe it or not. I’ve starting exercises five times a day to get my arm and shoulder to work again. It is painful but a relief to open up and extend my arm. Let the healing begin…

Stay tuned…