I will admit that I struggle with this whole season. And it is sad and heartwarming at the same time, the amount of people who seem to feel the same way. Expectations, family dynamics, travel, too much food, or not enough, all of it can consume you and leave you empty and depressed.

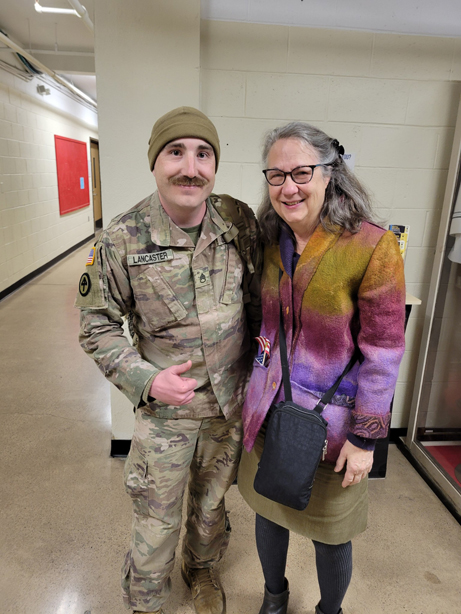

The woman behind me in line at the post office asked me in a friendly conversation starting way, if I was all ready for Christmas. I didn’t know her, a stranger, but she was eager to be friendly and just picked a way of striking up a conversation. I don’t think she was completely prepared for my answer, which was basically, “no”. I explained to her that I really had no plans for the holidays, as I had a son who was deployed, and hoped he would come home in time, but even if he didn’t, December 25th wasn’t some magical date where everything would come together. I had no plans, because there was no one to plan with.

The end of the year holiday season has always annoyed me from a business standpoint, it is largely just inconvenient, things are closed, places are overwhelmingly busy, schedules like deliveries are off, and I’m completely sick of emails begging for money, telling me how wonderful their products are for gift giving, “last chance on our special offer”, etc. I think January is really my favorite month because it is just normal. No holiday anything. Just 31 days of silence.

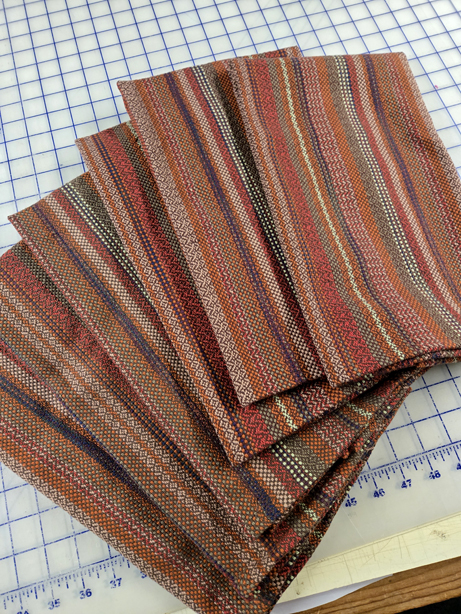

I don’t want to be a scrooge, yet this time of year really is, for me, magical, but not in the way that everyone seems to celebrate. My expectations are that it is cold, the gardens are asleep, the Winter Solstice is reassuring in that the light will come again, and that this is the season of generosity, of music, of gatherings with friends and strangers, and this is the season of one of the reasons for weaving. Towels. Lots and lots of towels. Even though my family is begging me to stop giving them towels, because their drawers are full, there are lots of others who have never gotten a towel, and are absolutely delighted with such a useful pretty gift.

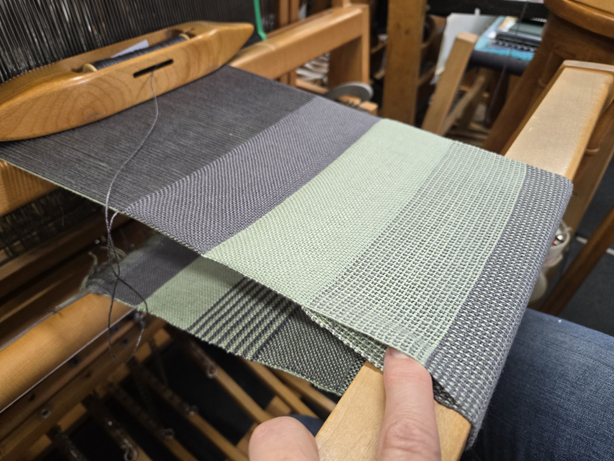

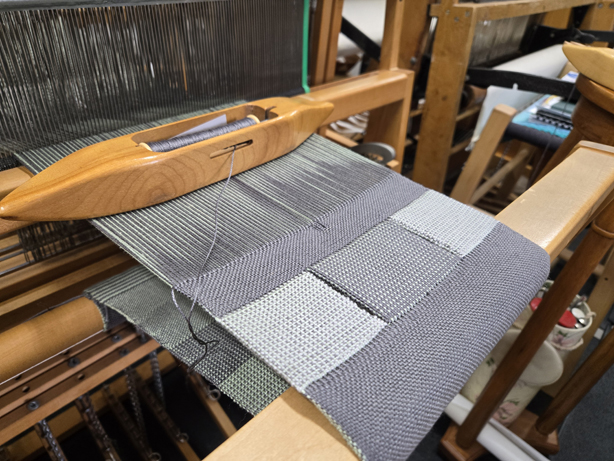

So I finished up the 9 towels on the warp, I’ve already given out a few, and decided that they were so much fun to weave, I should just tie on another warp.

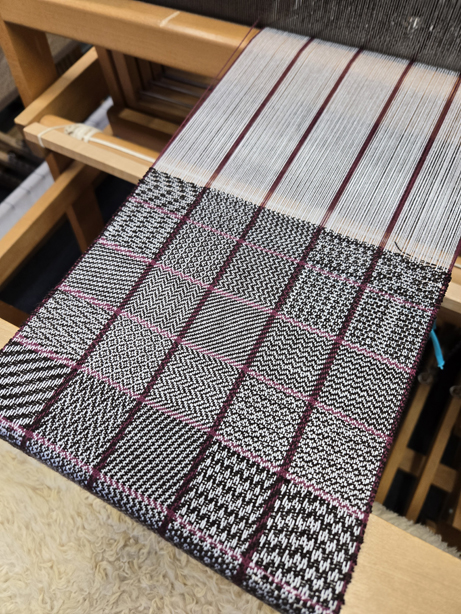

I looked at my vast stash of 8/2 cotton and randomly picked an icy warp.

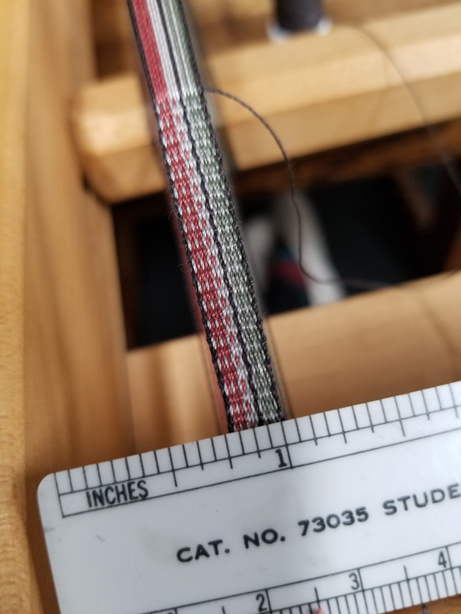

I wound another 10 yards…

Tied it into the existing warp,

Beamed it onto the warp beam,

And started to weave. I’m sure the warp would be even prettier with a dark weft, but I have a couple of cones of an icy gray, and decided that rather than buy more cotton to have a dark weft, I’d just use what I have. Head start on next year, or hostess gifts when I need them.

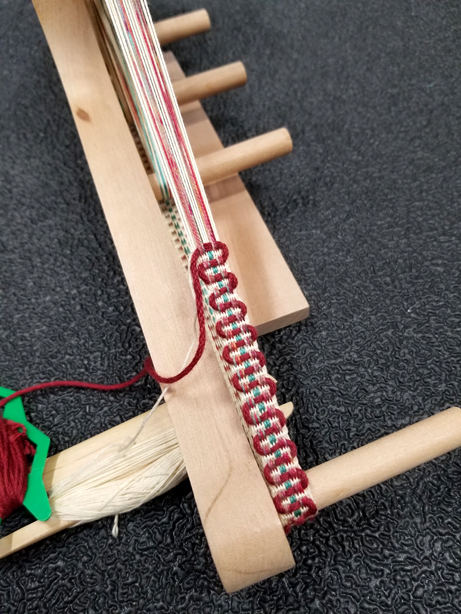

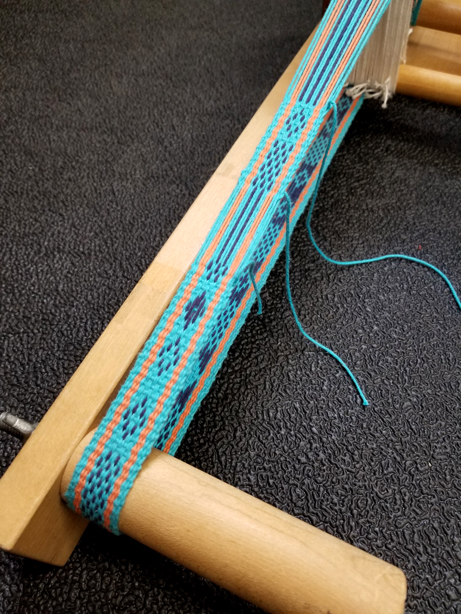

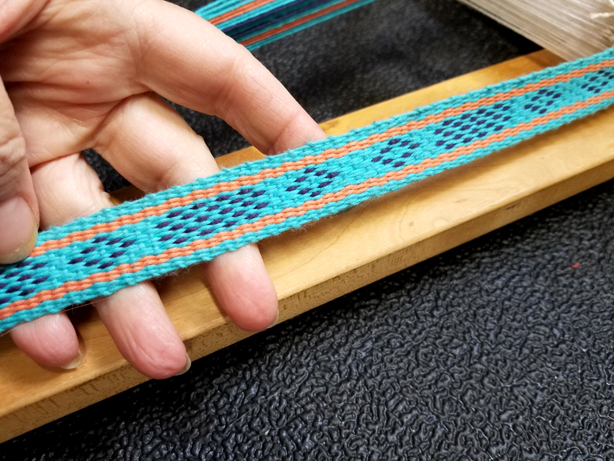

I finished up the Deflected Double Weave Warp I had transferred to my floor loom from one of my Structos. I grabbed another one of the Structos and started offloading that warp onto my small floor loom.

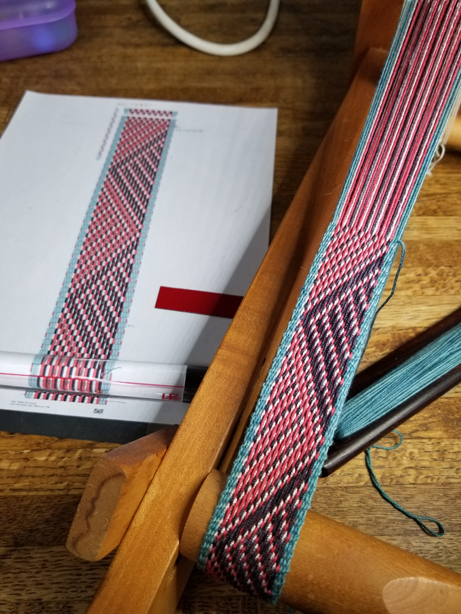

This one was set up in a four-shaft twill sampler, or gamp, and once it was on the floor loom, weaving it off was a breeze. There was only three yards of warp on this, so I’m just weaving it as a scarf, but it may turn into zip bags, or I don’t know, I don’t have to monetize everything…

My guild’s final meeting of the year is usually some simple project, a make it take it kind of thing, and this year’s project was actually a bit magical. We created little weavings in the round, around a ring covered in cotton.

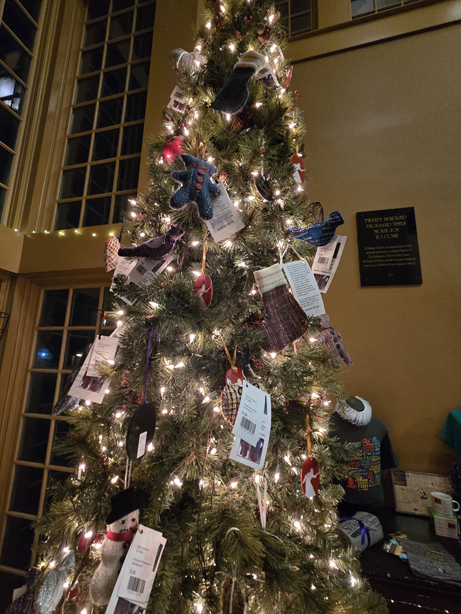

I took what was leftover from the guild sale, what didn’t sell of mine, and gave it to the Shakespeare Theatre of NJ for their small gift shop in the lobby of the Kirby Theatre at Drew University in Madison. I did this last year, and they ended up selling $500 worth of my items, and of course they get to keep all the money; my gift to them and the fantastic productions they do. There was a table of handmade items, some were mine, and some were by the ShakesPurls, a knitting group that supports the Theatre.

They had a large tree in the lobby filled with my ornaments.

They had a greeting card rack, and as I spun it around, I found all of my cards.

This is the season of music. And I’m really enjoying all the opportunities to play, dress up, rehearse, and I’m really really loving playing the cello. I practice at least an hour a day. We had both our holiday concerts with Montclair Early Music, many of you asked to see my costume, made up largely from just stuff in my closet I altered for effect.

I was hanging in the sewing studio, and started pulling out my more opulent fabrics that might work up into more costumes for the coming year. The public seems to love when we all come out in our medieval garb.

I have one more performance, this one tomorrow, in a local memory care facility. It is a great privilege to be able to take the gift of music to strangers, and maybe Christmas Carols might spark a bit of memory in those who have lost that ability. I love the music of the season, in all of its forms, though I will be glad to put away the holiday music and pull out new things to learn. We played Carol of the Bells at our winter concert a couple of weeks ago, which is Ukrainian, and after the concert, a couple of newly relocated Ukrainian families came up to the music director, with tears in their eyes, saying how much it meant to them to hear a bit of their homeland in this miserable war. Music has that power.

This time of year is for tying up loose ends, I love finishing up projects, and moving onto new challenges, and the greatest challenge I have ever taken on, was making this appliquéd cat quilt for my mom, from a Maggie Walker kit she bought in the 90’s. This was a really tough year for me, for many many reasons, and this quilt marked time, each month gone as I finished another block.

All of the last 100 pieces of the trumpet vine that runs through the central part of the quilt have been cut out, and today have been pressed under and ready to stitch on. I store them 10 at a time in sushi trays, stacked in order.

This is where the quilt is at this point, I’m seeing the end of an incredible project. I will miss it.

And the most important thing I want to share with all of you, is that he is home. My sister and her husband came with me yesterday to the National Guard Armory just outside of Princeton, and my son, who has spent the better part of this past year in Syria, is finally home. My heart is whole again. It will be a long road of reintegration for all of the returning troops, all he wanted last night was to go home to his apartment, with his beloved jeep that I kept repaired and running for him, and sit on his own couch with real pizza and a beer (no alcohol in Syria or any Islamic country). We brought him back to my house, where he grabbed his keys, hugged me goodbye, and took off to begin to pick up his life where he left off.

I’ll go and visit my mom who is 93, next weekend, and show her how far I’ve come on her quilt. That I still have my mom, and that she is still that amazing woman who raised me, is the biggest blessing of all.

Enjoy the magic of the season, the return to the light, the sleeping gardens, the opportunity to give gifts of music, things made from the hands, and just plain old friendship. Enjoy the music of the season, whether you play an instrument or not. And if you don’t, why not? I’m playing the piano again, glad I still kept the one I bought 40 years ago. And I play recorders, and now the cello. And there are always people to play with. You don’t have to be very good.

And I’m enjoying planning out my next year, what new adventures will I take on, what will my garden look like when everything wakes up? The night of the solstice it snowed about 4 inches. Everything is clean and white, and fresh.

Stay tuned…