My life is so full of really fun stuff, gardening is winding down, the visuals are changing daily. New stuff is blooming, (hello goldenrod) and other plants are dying back, going to seed, and looking wretched (goodbye milkweed).

I’m taking a natural dye intensive through Maiwa, in Canada (remotely of course) and watching each module, carefully taking lots of notes, and starting to scour some of the yarns and fabrics in the kit.

I’m taking cello lessons. Yep, something I always wanted to learn, it is my most favorite sounding instrument of all. First draw of the bow string and I was hooked. I practice furiously every day, hoping the pads of my fingertips will soon harden up! The photo from the teacher is for me to try to replicate proper posture…

And in all of that, honestly, I miss weaving. I love and have always loved the gentle process of a shuttle going back and forth, feet and hands in a rhythm that makes my heart sing. That and the cello… Often I listen to one while doing the other.

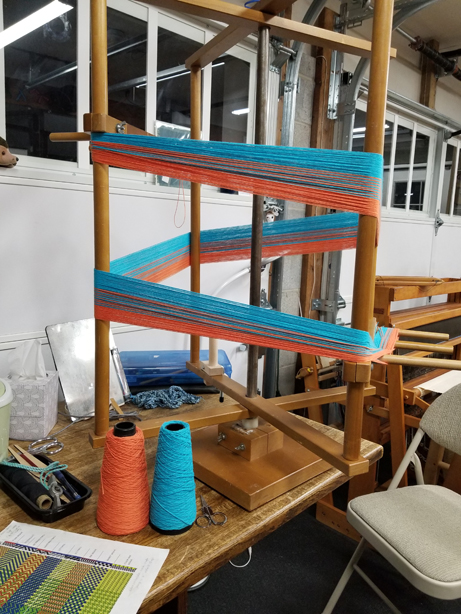

So here is the true confessions part. I have 17 table looms, all with interesting stuff on them, and I HATE weaving on a table loom. Really. Please don’t write letters telling me all the advantages of having a table loom, I know what they are, that’s why I still have 17 of them, down from around 3 dozen. There is nothing better for teaching structure, portability, etc.

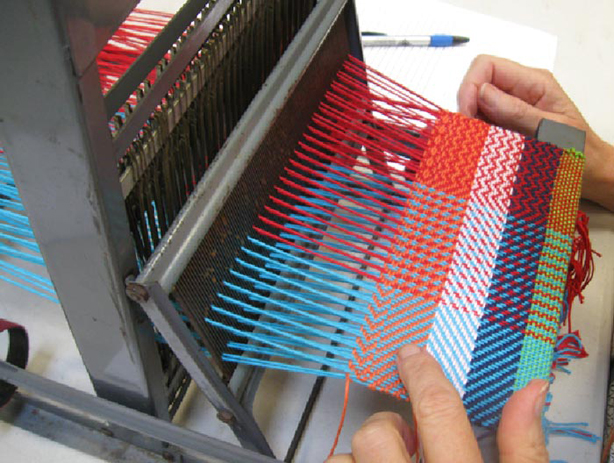

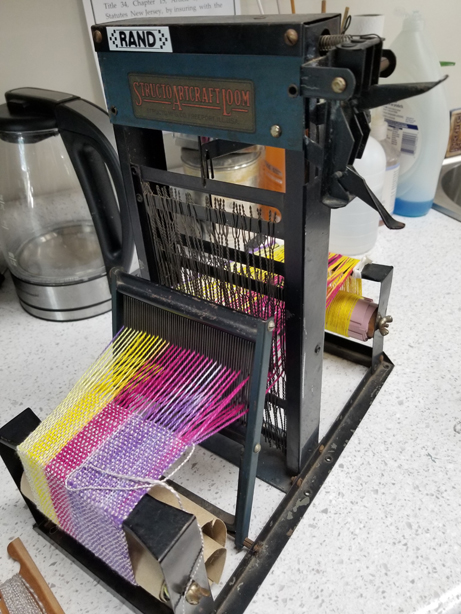

Before Covid changed the world and certainly my life, I was able to cart around an entire weaving studio in my car, and bring the world of weaving to the masses. I gave 12 of my sturdy little 4-shaft Structos to my weaving friend Anne Choi, who has a sheep farm and was excited to get them, and set up her own mobile weaving studio, concentrating in underserved areas that don’t have access to the joy of handweaving. She sent me these couple of images of my beloved Structos at the Newark Museum, here in NJ, this past weekend, another group of new weavers is born. Here is the link to her website.

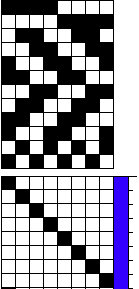

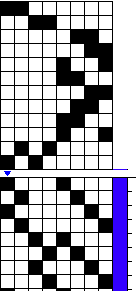

So, what about me… Back when I was doing this regularly, with my daughter in tow (she is now an emergency vet tech, and has little time for weaving), I started to build a group of 4-8 shaft Structos, with all different structures, envisioning a follow-up round robin, where people could try things like Summer/Winter, Huck, Doubleweave, Deflected Doubleweave, Honeycomb, Rosepath, etc. I put 4-6 yards of fine yarn, cotton or Tencel, on these little Structos and got each of them started and there they sat. This photo is from October 2023, it hasn’t changed…

One of them, actually a Leclerc 10″ wide 4-shaft sample loom, with spools on the back, had a Huck Sampler in linen, the spools had come with the loom, from my mother-in-law, and I thought it would be perfect to use up all that linen. What was I thinking…

I had no idea how much linen was on this group of spools, so I finished the yard and a half sampler, and there was still plenty to go. I picked one pattern and figured, how much could there be? So, I wove… And wove… And wove… This went on for the last year. I will be honest, it was painful… I couldn’t believe that the end was nowhere in sight.

So determined to clear this little guy if it killed me, I finally last weekend wove until I saw the end of the warp, which on a loom like this with spools, is the paper tape end that tucks into the flange of the metal spool.

And there it is. 7 1/2 freaking yards. Of 10″ wide huck in fine linen. I could have done this in probably a couple sittings on a floor loom. Instead it took me months. Sigh…

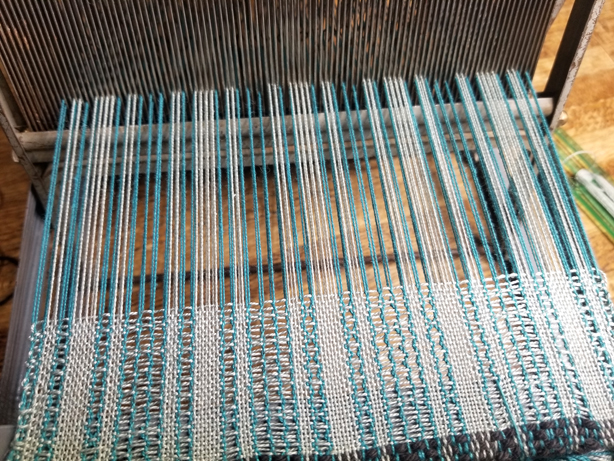

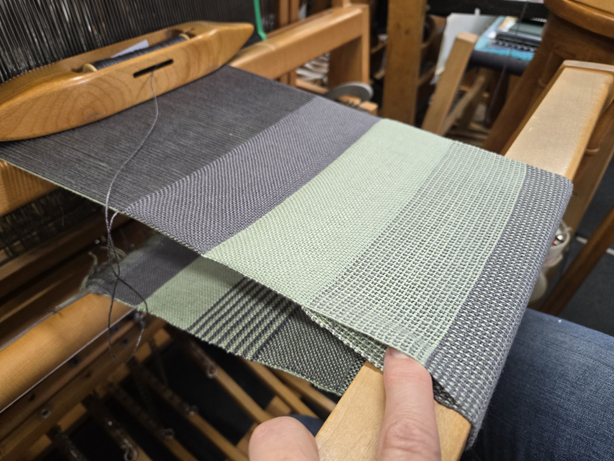

I had needed one of the small looms for the group that went to the college for my retrospective. So back in January I decided to actually cut off a Doubleweave sampler I started, and rethread, and beam onto a floor loom. Desperate to weave something, anything, I sat down this week, and pulled out Jennifer Moore’s Doubleweave book, and started in again. Oh the joy of using my hands and feet. I only have two more units left on this sampler, and I’m loving every minute of it. I have the more challenging ones left, quilting in a pattern and doubleweave pick-up, but with my feet working as part of the team, I’m looking forward to this.

That said, I looked at that wall of Structos and thought, well damn, I’ll just take them one at a time, and dump them onto my little 8-shaft Tools of the Trade loom, and carry on. I’m actually excited. The planning is done (though I have to convert from a lift-plan to a treadling sequence, I have software for that), and once I dump onto my floor loom I can weave like the wind.

I was chatting about this brilliant decision of mine with a weaving friend, and as I took a sip of my tea, she blurted out, “Friends don’t let friends weave on a rigid heddle loom…” (Sorry, if you aren’t a weaver you won’t understand this comment) I spit my tea across the table! Them’s fighting words in the weaving community. Truth be told, I feel the same way, and again, please don’t send letters telling me the grand virtues and benefits of a rigid heddle loom, they have their place, much like my beloved Structos, but I have a dozen and a half table looms, all set up that are not fun to weave on. My blog, my opinion…

So I continue with my dye studies, and while I baby sit the pots for scouring and mordanting, I work on the quilt. It is all together, and I’m now starting on the 380-piece trumpet vine that meanders all throughout the quilt. This is something I really don’t want to finish, I’m having too much fun…

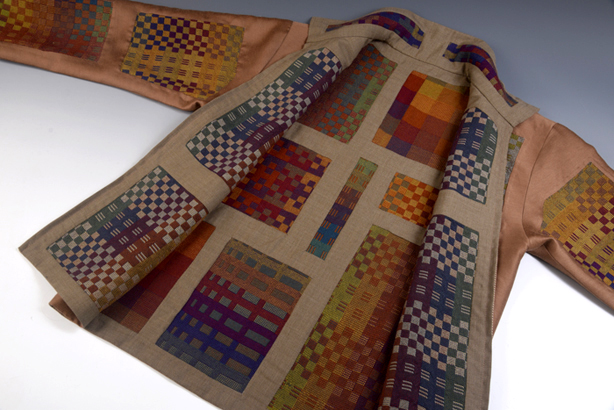

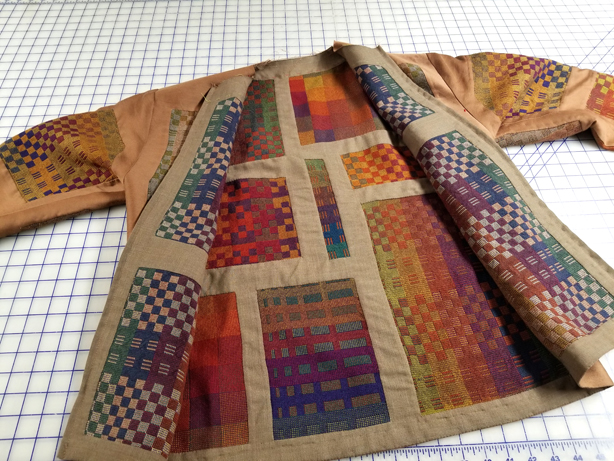

And, I looked at the calendar and realized I have exactly one month to make stuff for my guild sale. I still have lots of scraps left from my production years, though thankfully the pile is getting smaller. The pieced jacket I finally finished used up a nice amount. It will be for sale at the Jockey Hollow Weavers Show and Sale in Mendham NJ starting November 1.

I sold all those adorable bunnies I had last year, (blog post that shows the finished bunnies, scroll down…) and took the last of the mohair fabrics and scraps I had, and cut out four more. Mulder was doing his best to help.

So my days are full, garden for an hour, watch a module in the dye class for an hour, work in the dye studio for an hour, weave for an hour, do correspondence for an hour, practice cello for an hour, and fit in housework, processing a bucket full of tomatoes, basil for pesto (my freezer is filling up). Yes, I’m ridiculously busy, but having a blast, now that I am truly honest with myself and admitted I hate working on a table loom…

Stay tuned…