My last post had some serious color mixing and warp winding and I couldn’t wait to get everything on the loom and see how it would turn out. Just a reminder, here is the inspiration for the latest warp based on the insert/poster from a Magic Puzzle we had just completed.

I sleyed the reed…

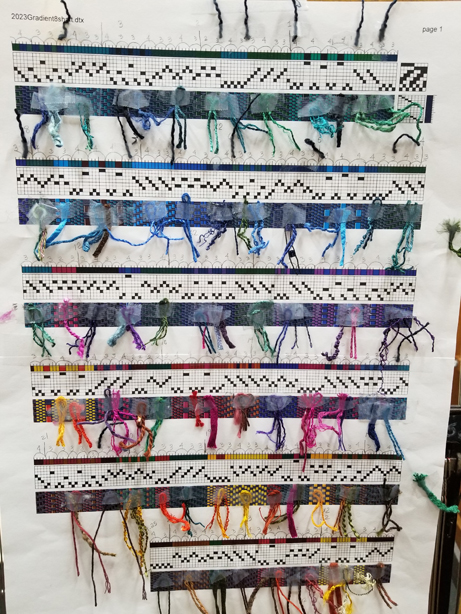

And because everyone wants to know about the levels in the reed… I warp front to back, for many many reasons, but the trick to working from the front, through the reed, and then the heddles, before beaming the warp, is to have multiple ends in a dent stacked in levels, so they can’t jamb up in front of the heddles. Cay Garrett wrote a lovely book on the subject, somewhere in the late 70’s, just as I was becoming a serious weaver, and I have never looked back. The book was called Warping All By Yourself, and almost every weaving guild library has a copy. Anyway, I tie horizontal cord around the reed, creating as many levels as I need for the threads that occupy the same dent. I grouped them based on size of yarn and structure, so I knew what went in which dent.

That makes threading a piece of cake, since I’ve already gone through and checked my original draft, and made sure there were no mistakes when sleying the reed. As it turns out, I had made two errors, I was short a thread in one of the groupings, easy to add before the warp was threaded and beamed, and I wound one too many of a different grouping. So I just dropped it.

The order in the reed keeps the order in which I wound the warp, so everything was just waiting for a heddle, and I was through this very complicated warp in no time.

I use a tensioning device from Harrisville Designs, which allows the threads to tension individually when beaming. Previously I used just a series of lease sticks, but I like the size of these smooth hardwood dowels.

And suddenly I was ready to tie on!

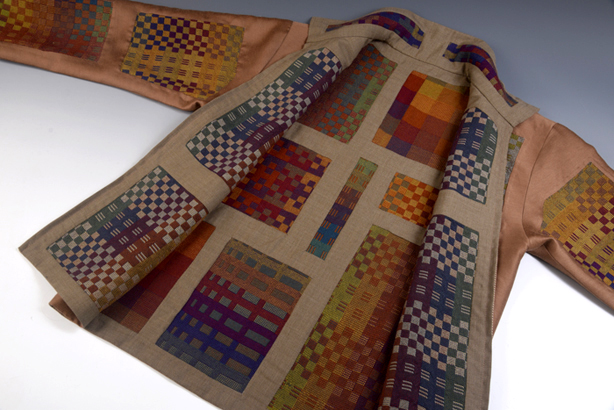

I selected a fine lambswool weft, which helps keep the rayon under control once the fabric is off the loom and washed, This is definitely a warp faced series of structures, and there is a lot of slippery rayon. The draft is based on the 12 shaft version from my lengthy article in Heddlecraft Magazine, issue #38, but I was able to convert the draft to 8 shafts, and maintain the integrity of the original.

I’m really happy with this so far, it is exactly what I envisioned. Which is always fun when things work out!

Meanwhile, I apparently am on a quest to warp all the looms. I have 49, have I mentioned that? 15 are always reserved for beginning weaving classes, but the rest, many of them little Structos or Leclerc sample looms, I have been setting up with explorations of various structures, for my entertainment, but also because it might be fun to have people come and play. And there is always the hope that one day I’ll carry a little loom outside and sit in the garden and weave…

One of the looms I got from that stash from a school in California still had to be refurbished, so I set out to do that yesterday.

I needed a different reed, obviously a new front apron, and I won’t even discuss the heddle situation. I did a previous blog post on heddle etiquette. Obviously this loom had not been exposed to that.

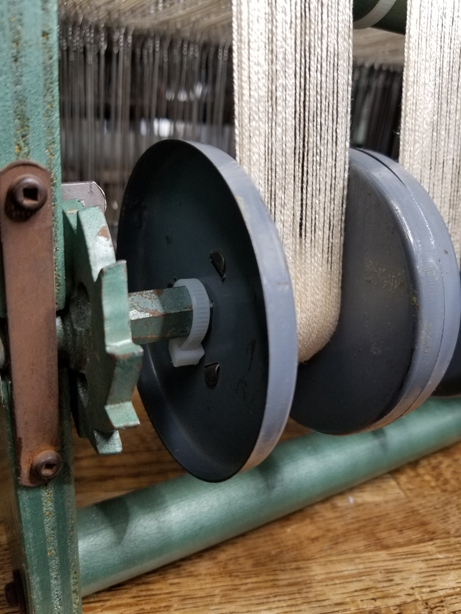

And so I replaced the apron, fresh and white. And I changed out the reed, I needed a 12 dent reed, which fortunately I had. I have five of this particular loom, and I’m fortunate that two of them had hex warp beams, that fit Structo spools.

So I swapped out the warp beams and added the spools, and though I’m running low on Leclerc heddles, which are a different length than the thousands I have for the Tools of the Trade Looms, and the Macomber, which is different from all those, I did manage to find enough to put on this little Leclerc, with all of them canting in the same direction.

For those who aren’t weavers, skip this section, just look at the pictures at the end. I’m including a little tutorial here because I’m going to be asked, and I might as well include it in the post. How do you warp the spools? I use many different methods, but the easiest is just to make the chain warp, and warp from Front to Back.

Once the ends come through to the back, they have to be attached to the spools, using a strip of paper tape, the kind you wet, and that little tab then slips into the metal flange in the spool.

The next step involves a bunch of zip ties. I buy these by the gross. I put a pair around the hex beam on either side of the spools so they don’t travel left or right as I beam.

Then I put a pair on either side of each of the warp bundles that will load onto a spool, across the back beam. This channels the warp into the spools. It is important as you wind that you keep an eye that there isn’t any uneven build up, and that you hold the warp tight from the front as you are beaming.

And there you have it. I put six yards on this loom, of 10/2 perle cotton, and probably didn’t even fill the spools half way. No packing needed!

A couple of years ago, I saw a fabulous social media post from Elizabeth Tritthart, historicweaving.com called 100 Horizontal Stripes. They were just beautiful, and Elizabeth figured out how to take old cross stitch and needlework patterns and convert them to drafts for pick-up. Typically, she works on a draw loom, but this book had information on how to work with just four shafts, which my little Leclerc had. I’ve been wanting to do this for a while. And I also have old needlework books and leaflets…

And so I started weaving. Yes, this is painstakingly slow, but slow cloth is a thing, and I’m not in any hurry. Each design is separated by a “ribbon separator” as she calls it, a three pick basket structure that looks like a little chain. I ended up using doubled embroidery floss for the pattern threads, as I have tons of it in many different colors.

And so I’ve had the most productive week, I walk into the garage/studio every morning smiling, and my looms smile back. I’m racking up good loom karma, each loom that gets refurbished and warped has a new lease on life and gets to play in my colorful sandbox of fiber. We are all happy campers. This is like a summer camp that goes year round.

There are a couple more looms I want to warp up, and then I’ll just weave away, for the rest of the year, always thinking of what I want to try next.

Stay tuned…