Mohair is not for the faint of heart…

But first, a back story…

When I graduated college in the mid 1970’s, I began my “career” working for a mall craft store, teaching all sorts of craft techniques, while acquiring my first loom, which I still have. That loom arrived in the spring of 1978, and as I slowly transitioned away from my minimum wage mall craft store job, into trying to make weaving as a living pay for itself, the first stop was as a production weaver for a pair of designers who worked in Mohair. Yeah, that really fuzzy yarn that is a bear to work with.

I had answered an ad, looking for a production weaver, and though I had no idea what a production weaver was, I had a loom, and I had the ignorance of youth, to make me think I could do whatever it was a production weaver needed to do. I had the right equipment, and after weaving off a sample of the type of fabric they wanted, my first assignment arrived, a gigantic box filled with cones of mohair, and I needed to turn that into 30 yards at 46″ wide. Which in itself was going to be challenging since my loom technically was only 45″ wide. But the innocence of youth, and thinking there was nothing I couldn’t do if I could just figure out how, allowed me to plow forward, undaunted, and figure out how to sectionally warp 30 yards of fuzzy yarn that had, as my friend Robyn Spady calls them, tentacles that just clung to each other in the most annoying way.

I learned to do a direct tie-up, the only way to get a consistently clean shed, and I learned to warp directly to my warp beam, via sectional, because there was this very visible force field of fuzz, that kept the yarns parallel and apart, and I rigged up a system to go right from the cones to the beam. I had no support from my college professor, I had no support from guilds, or the internet, or YouTube videos. I just had to figure it out. Failure is not a word a 25 year old understands. I was armed with Davison, Black, and Atwater. And I think a book by Regensteiner. I don’t think any of them mentioned mohair. But I had a catalogue from Leclerc, with a tension box and vague directions, and a sectional beam on my Tools of the Trade Loom, not that I had a clue what a sectional beam did, but it was an option and I went for it when ordering the loom, well, because the ignorance of youth?

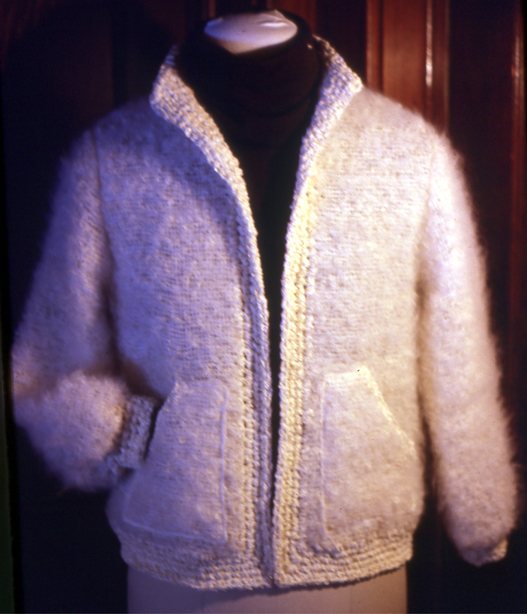

I wove hundreds of yards of this 6epi fuzzy stuff for this pair of designers over the next couple of years. At the time I left them, part of me never wanted to see another fuzzy yarn again, and part of me did enjoy the luxury that mohair produced. I have no images of the work I did for the mohair designers, it wasn’t my work to photograph. I did though, get to weave/keep one of the coats made from their mohair yardage, and apparently I found an image of a vest I made, though I’m not sure where that vest is, I think it might have been a commission? And I found an image of a prototype I did of a running jacket, of mohair, crocheted around the edges with chenille, as an assignment from the mohair designers.

Over the next few years, as I developed my own line of handwoven clothing to sell at craft fairs, I initially avoided mohair at all cost. It was also expensive, and I didn’t have a lot to invest. And there were other weavers who did handwoven clothing and sold it in craft fairs that wove mohair. Eventually I settled on a mixed cellulose warp, that is rayons, and cottons, and combinations, with a rayon/silk weft. I would put 30 yards of warp on a loom, weave half with the rayon/silk weft, and half with a mohair weft, which allowed me companion pieces. The cool thing about mohair, is that while the cloth is still under tension, before you advance, you can brush up the mohair to get a hazy pile. All those tentacles can be brought to the surface to create a luxury fabric.

Years later, realizing I still had a lot of mohair on my shelves, left from my craft fair days, I decided once and for all to use it all up, and I did a plain weave fabric, different from the 6epi with a doubled weft at 4ppi than I wove for the mohair designers. I made this really lovely cape. I sold it some time ago, and thought my years of mohair were finally over.

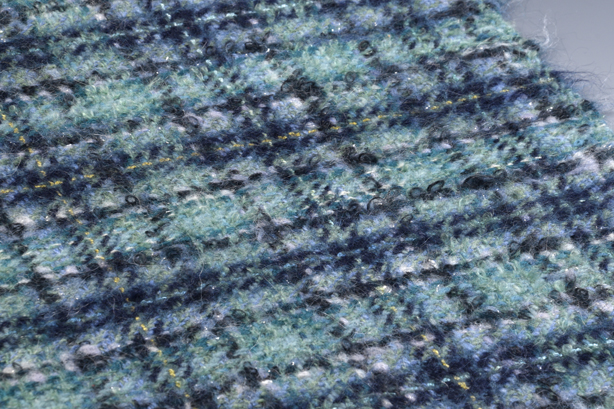

But no, apparently those tentacles breed, and I soon realized that I still had a lot of mohair on the shelves. And so I took all the colors, and lined them up in a gradient across the warp, and wove the fabric for this.

And then with the leftover fabric, created this with my 800 Collared vest pattern.

By now I just had bits and pieces, odd balls that didn’t really amount to much, and so in desperation to use them up, I created this yardage, which was a plaid, so calculating how much to use in the warp and how much to leave for the weft was challenging.

The last couple of years saw the loss of a number of beloved weavers in the guilds I belong to. Stash/estate sales are great ways of filling in yarns that I remembered from the past, that aren’t available anymore, and picking up some oddities that I might not buy on purpose. Though it is never my intent to purchase anything when I go to these stash/estate sales, often things just follow me home. And apparently the mohair just shows up in my car. (I also blame my daughter here…)

In rearranging my shelves to accommodate yarn I actually purchased, I discovered a ridiculous amount of mohair had somehow repopulated my shelves. And back in December, on a visit to my mom in her retirement community apartment, I noticed a throw on the back of her couch, that I hadn’t remembered seeing in many years. I realized it was one I had woven during my years or just after, with the mohair designers. The sett and picks were the same, and it was still in glorious condition and still warm and luxurious.

I pulled out this ridiculous amount of mohair stuffed in bags, on shelves, and in a wardrobe in the guest room and realized I needed some huge project to use it all up. The great thing about weaving is you can weave yardage. Lots of yardage. I separated the mohair, which was mostly balls and skeins, which are a lot fuzzier than coned mohair, into color combinations.

And I isolated out the most neutral of the bunch that I thought I could create a nice warp that would be background for all the color groupings.

And I carefully weighed and calculated what I had and realized, at 46″ wide, I could put 18 yards of mohair on the warp beam and make a decent dent. (I went back to my original loom, which is still only 45″ wide and it greeted me with open arms. I haven’t woven on that loom for a few years, mostly my daughter uses it.)

So that put me in a dilemma, how to get the 18 yards of fuzzy tentacle laced yarn onto that beam. I had moved the sectional beam down to the lower back beam position, did I want to switch them out? Did I want to wind 18 yards and do a front to back like I normally do, would the tentacles be obnoxious and cling to each other and the reed dents and the heddle eyes? My warping mill only holds 10-12 yards. Should I use my AVL mill, but that may exacerbate the fuzzy tentacles. But I could wind 18 yards on that, two inches at a time. I didn’t have tidy cones to feed right into a tension box, I had a bunch of unruly balls, skeins and only a few cones. And I found out quickly that winding a 2″ wide 18 yard warp with a cross, and chaining it off, created a ripe breeding ground for those tentacles to just latch on to each other and make life really challenging.

So the drama here is I remember being 25 years old, and knowing nothing, and yet in my ignorance, I somehow managed to dress a loom with 30 yards of mohair and create a career. Now, more than 40 years later, I have so many options, and know so much more, and am sort of paralyzed in how to proceed because I know too much. I miss the blind innocence of just plowing ahead because you don’t know any better.

My daughter helped me wind the first bundle onto the sectional beam. It was really problematic. I couldn’t believe this was such a challenge. I just kept thinking how did I possibly make this work more than 40 years ago. Using the same loom. Because the mohair has a built in force field, that keeps the yarns slightly away from each other when parallel, I grabbed a large watercolor tablet and used the heaviness of the paper to wind all 18 yards off the AVL warping wheel, around the tablet, and that kept the mohair tentacles quiet and “standoffish”. Like a force field.

And I could sit on the floor behind the loom, challenging at my age, and carefully wind the warp onto each section, while unwinding the watercolor tablet filled with warp, which I had passed under the loom, to sit on the floor beside me. It was bloody brilliant, and I hugged my 25 year old self and we congratulated each other. I have never been so proud of myself for making this work.

Yesterday I threaded and sleyed…

…and tied onto the front, and started to weave. I even used the same wooden bobbins in the X-Large Leclerc boat shuttle that I had used 40 years ago, and still had the same slicker brush for brushing up the pile. There was a hand memory that even 40 years later, I just knew instinctively what to do. At this point, I’m planning a series of blankets to use up all the mohair, but that could change as I move through the 18 yards of warp. The quantity of mohair in the stash is starting to rapidly reduce. Meanwhile, I really hope that there are no more stash/estate sales in my immediate future.

I do want to mention the passing of one of the greats, Sarah Fortin, from New Hampshire. She was a skilled weaver, especially in double weave, and was my strongest competition teaching garment construction for handweavers. She was really talented, and the kindest and gentlest teacher, craftsman, and human being I’ve ever met. She always came to visit when I taught at Harrisville Designs in NH, and we often met for dinner when I’d be in the area. She was only 71. She had years ahead of her to design and create more incredible garments. I will miss her and her perspective. And it makes me realize how vulnerable we all are to the marching forward of time. The 6 year anniversary of my husband’s passing was Friday. He passed away Father’s Day weekend, which will always haunt my children. He died at 65, the same year he planned to retire and experience all life has to offer. He never got to experience retirement. I wake up each day with a huge gratitude, having been given one more day, especially after my tragic fall in December, breaking my shoulder in two places. I am mostly healed, and was also wanting to try to weave 46″ wide, to really push my shoulder to gain maximum rotation and reach. So far so good.

Stay tuned dear readers, hopefully more to come, but life is short, and we never know… Live in the moment, and make the best of each day.