I love to putter around, when I’m not super focused on any one project, and I’m reluctant to get focused on any one project because I’m leaving in less than a week for two back-to-back conferences, with a 12 hour turn around time in between. (I’m trying not to think about the whole airline situation, and how one missed connection can snowball into a nightmare…)

Anyway, there is nothing I can do about any of that, just let go and hope for the best, so I’m just doing what needs to be done, and enjoying the little stuff. I’ve made such tremendous progress on the book shelves, they are pretty much sorted in my studio, with a huge bag of trash removed, I can hear the studio breathing a little sigh of relief. I still have to organize the fashion books in my bedroom library, some of those are so big, they wouldn’t fit on the proverbial coffee table if I chose to display them there. They could actually be a coffee table…

The crock pot is still cooking away, yesterday’s color was “myrtle green”, which is a pretty teal, and today I’m cooking Rose, and I’m getting to the bottom of the fleece. At this rate, I’ll have the whole fleece plus some other errant stuff I found, dyed by the time I leave for Colorado next week.

Yesterday afternoon I spent a couple of hours, cutting two yard packages of interfacings, some for orders, some to ship to the conferences, and some to refill my supply in the studio. This is a boring job, and it requires a complete clean off of my

Yesterday afternoon I spent a couple of hours, cutting two yard packages of interfacings, some for orders, some to ship to the conferences, and some to refill my supply in the studio. This is a boring job, and it requires a complete clean off of my  cutting table, because I need the room to layout 100-200 yard bolts of 60″ wide interfacing to be able to unroll and cut off two yard pieces. Then they have to be bagged and tagged, and ready for shipping. So I listened to the last couple of episodes of Weavecast while I unrolled and cut, tagged and bagged.

cutting table, because I need the room to layout 100-200 yard bolts of 60″ wide interfacing to be able to unroll and cut off two yard pieces. Then they have to be bagged and tagged, and ready for shipping. So I listened to the last couple of episodes of Weavecast while I unrolled and cut, tagged and bagged.

In case you are wondering what interfacings I’m cutting, I use two primarily, for a fusible underlining with handwoven fabrics, one is a fusible knit nylon tricot, and the other is a texturized inserted poly weft interfacing, both have a crosswise give. Each gives a different kind of support, the tricot gives a crisper flatter feel, and the poly weft gives a loftier fuller kind of feel. Both come in black and white. I encourage sampling… 🙂

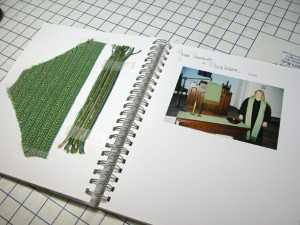

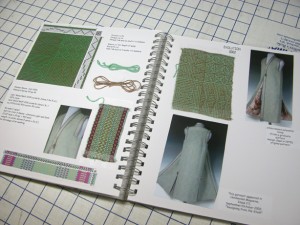

Update on the reworking/salvaging of my poor design journal. I added the pages for the purple and green paraments and was pretty surprised to find out I had no notes on sett/size/yarns, etc. I’m going to assume I just used all the information from the previous paraments, and there wasn’t much to figure…

Update on the reworking/salvaging of my poor design journal. I added the pages for the purple and green paraments and was pretty surprised to find out I had no notes on sett/size/yarns, etc. I’m going to assume I just used all the information from the previous paraments, and there wasn’t much to figure…

Now I get to the fun pages, these are ones where I took all kinds of copious notes, and figures, and I’ll be damned if I can decipher half of what I wrote. I spent an hour or so earlier today, just trying to recreate what I actually did, what I didn’t do, and what information I needed to actually transfer. I added photos of the finished item, and I was able to beautifully recreate the notes for my infamous Evolution piece, that appeared in Issue 111 of Handwoven Magazine. (Sept/Oct 2002).

Now I get to the fun pages, these are ones where I took all kinds of copious notes, and figures, and I’ll be damned if I can decipher half of what I wrote. I spent an hour or so earlier today, just trying to recreate what I actually did, what I didn’t do, and what information I needed to actually transfer. I added photos of the finished item, and I was able to beautifully recreate the notes for my infamous Evolution piece, that appeared in Issue 111 of Handwoven Magazine. (Sept/Oct 2002).

I thought I took great notes, but if there is anything I’ve learned, it is how important note taking is, and how important it is to label what every number is. Never just write a number, always identify what the number is, like 3200 yards per pound, or 20 e.p.i. This is a great exercise in note taking, and recreating old work. I’m glad I’m taking the time to do this. I also found a copy of the inkle draft I used (my design) to weave the inkle bands that made up the neck trim. The fabric for this vest was an 8 shaft shadow weave which I found in the now defunct Weavers Magazine, Spring/Summer 1999, pg. 48.

And last night, I spent a number of hours playing with my new puppy. No, not that kind of puppy. The electronic kind. I got my new EeePC yesterday, a little mini laptop NetBook. It is sooo cute, and sooooo tiny. It will slip in my Vera Wang purse. I’m trying to load in all the software I need, and figure it all out myself. I do rely on my techie husband way too much, he is so good at what he does, but I don’t stay with something and try to figure it out, like I would with the loom or the sewing machine. I usually quit too soon and just ask him. And I won’t ever be any good at this if I don’t keep trying. So this morning, I managed to figure out how to manually configure my email account into it. And it worked! 🙂

And last night, I spent a number of hours playing with my new puppy. No, not that kind of puppy. The electronic kind. I got my new EeePC yesterday, a little mini laptop NetBook. It is sooo cute, and sooooo tiny. It will slip in my Vera Wang purse. I’m trying to load in all the software I need, and figure it all out myself. I do rely on my techie husband way too much, he is so good at what he does, but I don’t stay with something and try to figure it out, like I would with the loom or the sewing machine. I usually quit too soon and just ask him. And I won’t ever be any good at this if I don’t keep trying. So this morning, I managed to figure out how to manually configure my email account into it. And it worked! 🙂

I’ve got Photoshop Elements loaded in, and I transferred my PowerPoint presentations over manually, because I still haven’t figured out how to access the in house network. But I’m working on that…