When I traveled on the road, I had a woman who would come to clean the house every couple of weeks, which was really important. The last thing I wanted to do when I’d get back from a long trip was to clean my house, mow the lawn, and take care of all the things houses need. Mostly I was just getting things unpacked and repacked for the next trip.

When Covid hit in March of 2020, and my entire teaching schedule was erased, of course my housekeeper was the first to go, since it wasn’t safe at the time to even come to my house, as we didn’t know how this dreaded pandemic was transmitted.

My yard crew kept coming, they were outside, and though I tried hard to get out there and weed and do general yard and pond maintenance, I found it impossible to do all that and have a life.

But my house…

I remember talking to my mom in the early days of the pandemic. I might even have written a blog post about it. She is 90, and at the time was dealing with a husband who was gently slipping away, in fact he passed in December a year ago. The facility where they lived could no longer safely send people to clean, make beds, etc. She said to me, “I’m a pro at keeping house. Did it my whole life. I can clean a room a day and keep on top of this place. Piece of cake…” Yay mom!

My house is a lot larger, and I have animals, lots of them, and I have those studios, with lots of looms and stuff. But still. Not being proactive would mean I’d drown quickly in animal hair, dust, yarn bits, clutter, and did I mention animal hair?

So I got a plan. I print out a weekly schedule of my life, and pencil in one room a day, to vacuum, dust and otherwise scrub depending on what the floor surface is, tile, carpet, wood, or a combination thereof.

I’m a tidy person. I have to be. Clutter not only messes with my brain and focus, but it also means I’m endlessly loosing stuff. Not a thing you want to happen when you are packing for a trip to teach. When I shut down the house and head off to bed each night, everything is back in its place.

And so, a couple weeks ago, it was the day where I planned to dust and vacuum the studio. I think it was a Sunday. Personally, as tedious as dusting and vacuuming are, there is a lot of creativity that tends to happen when I just stay in the moment, and concentrate on what I’m dusting. There is always WQXR, Classical public radio station from NYC playing on my Alexa, and I just take my Swiffer on an extension pole and dust every horizontal surface I can reach. It takes about an hour for the weaving studio, more or less depending on how lost in the moment I get. I’ll be dusting a loom and stop and think, gee, I really need to get that warp off… I’ll be dusting a shelf of yarn and think, gee, what would happen if I combine these two together… I’ll be dusting a shelf of mixed fiber tools and supplies, and think, wow, I haven’t done any needle felting, kumihimo, lace making, inkle weaving, wet felting, basketry, water color, etc, in just ages…

There is something zen like about dusting and staying in the moment.

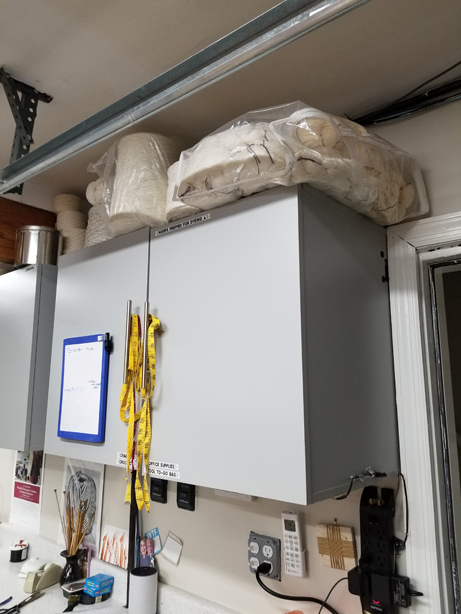

And so as I rounded the perimeter of the studio, before working in the interior on the floor looms, I started dusting the top of the right hand cabinet over my dye sink area. On the top of the right most cabinet is a bag. In the bag are a bunch of 10 yard white warps, give or take, that my son wound for me years ago, for warp painting. I remember being mad at him for some errant teen stupidity, and as punishment, I made him spend the day in my studio winding white warps.

The warps were badly wound, on a mill, but there they were, just collecting proverbial dust.

I thought, gee, I need to dig those out and do something with them…

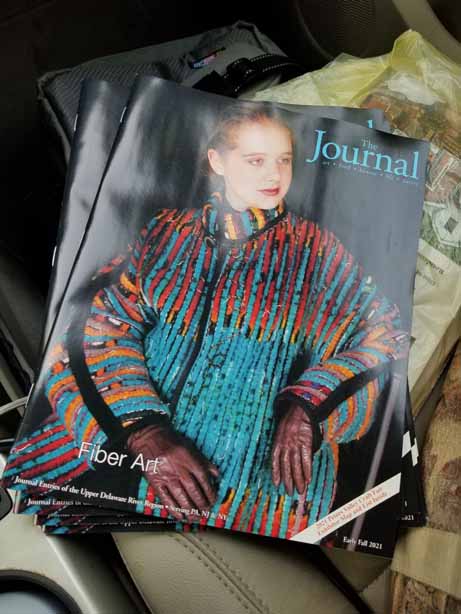

The next day one of my local guilds was having a presentation by batik artist and ice dyer extraordinaire, Jessica Kaufman of Waxon Studio. Jessica gave the absolutely best presentation on ice dyeing for the MAFA fiber conference last summer and I was immediately hooked. I wrote a post about all the cool things I ice dyed. She taught me to “trust the muck”.

Anyway, I listened to her lecture again, through my local guild, remote of course, and thought, you know, there are those white warps. Why can’t I try to ice dye one of those warps?

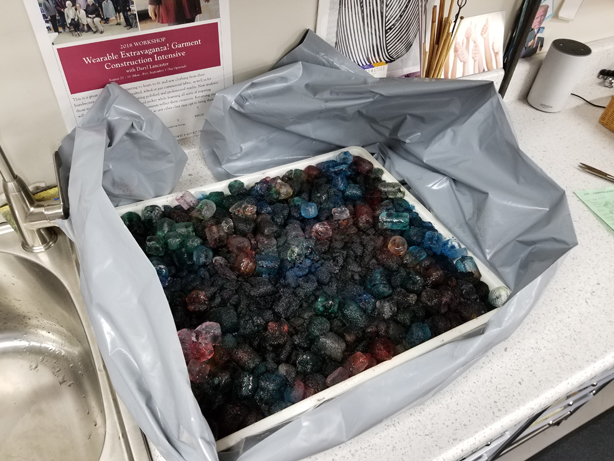

I picked a shiny rayon, 10 yards, 512 ends, and found the biggest container in the studio. It wasn’t that deep, but with my trusty turkey baster, I could syphon off any excess muck as the ice melted.

I used a lot of dye sprinkled over the ice. I presoaked the warp in soda ash solution as per her instructions.

I let it sit for 24 hours after the ice melted.

I dumped it in the sink, muck and all and rinsed and rinsed and rinsed and was pretty disappointed. There were a lot of white areas that never got the dye. The exposed part of the 10 yard warp was lovely, but the entire back side, the part soaking in the muck, was still white. Trust the muck.

Once it dried, I resoaked it in soda ash, and then did the whole process all over again. White side up. 24 hours after the ice melted I dumped the whole thing in the sink and there were still large amounts of white areas that just looked like mistakes. I know it was too much to dye at once, this whole process should have been on a warp a quarter of the size I was using, but I’m resourceful…

I didn’t take any photos of that second version because it was still in the stainless dye sink and I remember rinsing and rinsing and then just getting pissed, stopping up the sink, pouring the rest of the soda ash over it, pulling up any white areas I could find, draining the soda ash right out the bottom of the sink, and then just sprinkling dye directly over any white areas my gloved fingers could find. At this point I was figuring the warp as a failure, so whatever…

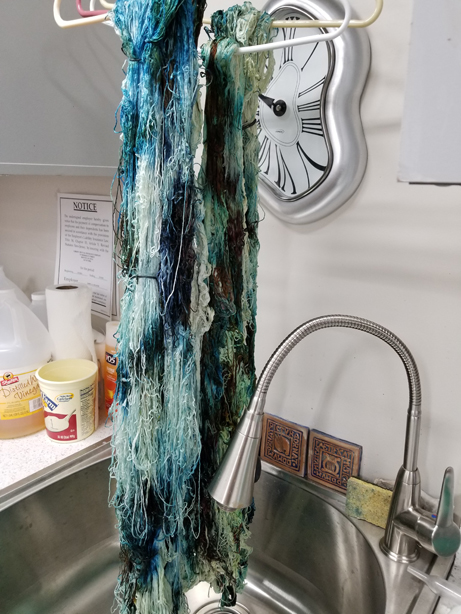

The next morning, everything looked like a complete grey/black disaster, but I opened the drain, and started rinsing. And rinsing. And rinsing and soaking and rinsing some more…

When I hung the warp to dry, I couldn’t believe what I had. I’m sorry the photo is blurry.

It took three days to dry, and even then, there were spots I just couldn’t get dry so I draped the whole mostly dry warp directly under the split ductless heating system.

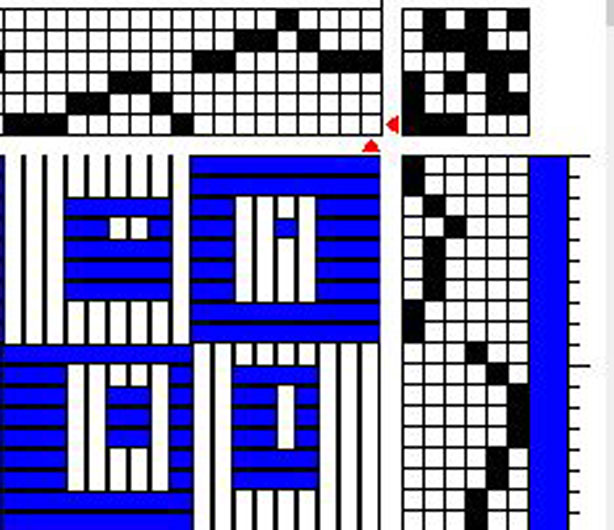

I was so excited by this warp, that looked like a complete mess, but the dye chokes held, that I immediately dropped everything and started figuring out what to do with it. I settled on a simple Twill Crackle from Davison, which would use a black weft as pattern and tabby. With 10 yards, I wanted this to be a single shuttle warp.

I sleyed.

I threaded.

I started beaming.

I tied on

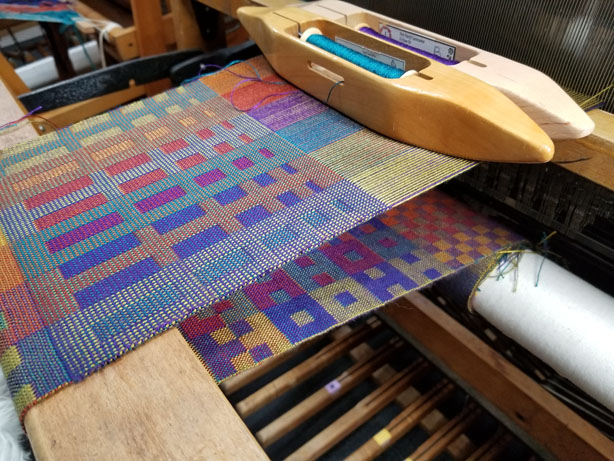

And I wove. Can I tell you that this thing, that I can’t reproduce is just smiling at me, no shimmering at me, and that this is a lovely happy accident that happened all on account of I was dusting…

As a matter of fact, once I post this blog, I’ll be heading back to the studio because today’s room to clean is once again the studio… I’m going to see what other trouble I can get into…

Stay tuned…