At least I can reasonably state that the last two weeks have been if nothing else, entertaining…

I got a notice that my custom Pella Window was ready to install and they made an appointment for 10 days ago. Pella installers came, and did a fantastic job replacing the old, short double-hungs, and now I have a beautiful window facing east, to catch the rising sun, and look over my fantastic gardens, as they carefully begin to come to life after the long winter. Sounds almost magical doesn’t it?

I stood looking out of my beautiful window and think, if I hadn’t had the flood, if the day after Christmas they hadn’t completely gutted my den, where it rained broken pipe water from the room above, through the ceiling fan, if I hadn’t experienced any of that, I wouldn’t have this incredible view, and I wouldn’t have met all the fantastic workers who were kind, efficient, knowledgeable, and though we could rarely communicate with English, we managed to get the important concepts across. I genuflect in gratitude.

The restoration crew came in with a vengeance, the day after the window was installed. Insulation, drywall, spackle, more spackle, sanding the spackle, they were like a crew of bees busy in the hive. The painters started two days later.

All of this required me to be around. The whole time. Partly to answer questions, and partly to make sure that the animals didn’t interfere with any of the messy jobs they were doing. I stayed most of the time in my weaving studio, where I could let the dogs in and out and not disturb the workers. Which meant I got a lot of work done.

Though, I did, on the one day between drywall people and painters, help with a loom rescue. A weaver in the area, well over 100 years old, had passed, and her relatives wanted to donate what weaving supplies there were, to my local guild. In addition, there were two looms, and all of us, do what we can to rescue looms, as the house will be bulldozed within a couple weeks, including the contents. One loom, in the basement, an old Swedish style barn loom, my friend Susan has been sending around notices to area fiber people/guilds in hope that someone has room to rescue a large loom. But Susan and I drove over, with tools in hand, to rescue a 25″ Macomber, left on a porch, covered in mouse poop, hence the mask and gloves, in sad condition, but with some TLC, and a lot of elbow grease, my friend will bring it back to life. There is always good loom karma when you go to the effort to rescue a loom.

This all seems fantastical within the last 10 days, but I’m rather impressed at my ability to make good use of time.

First up, I’m taking a workshop through my guild with Natalie Drummond in Deflected Double Weave, the first week in April. Which meant I needed an empty table loom with 8 shafts. Which I didn’t have… Around 40 looms, and the one I needed wasn’t empty.

I’ve gotten real good at moving warps from one loom to another. The loom I wanted had the last remaining yard of a Rep class from last April, with Rosalie Neilson. I really didn’t want to waste it. So I spent an afternoon moving it to my floor loom.

Problem was, within the reems of documentation, I couldn’t remember exactly how to do this structure. I know it is alternating thick and thin wefts, but the myriad of designs in her handouts, all worked off Profile Treadlings, which I did easily in the class on a table loom, but couldn’t for the life of me remember how to interpret them. I spent a lot of time just sitting and staring and trying to work out what was there, right in front of me. At some point, working in my office (with the animals in tow) on my desktop computer with my weaving software, I finally figured out how to interpret the profile treadlings and create a treadling sequence I could follow. Should have taken better detailed notes…

So I will have this lovely mat, and this loom will be cleared within the week.

That left prep for the Natalie Drummond workshop. She requires a complex warp, hand painted with additional solids in varying values. Honestly, we only got the instructions just about the time I had to lock myself away with the animals, not her fault, and with only a month till the workshop, all the construction, gardening chores starting soon, (where I live it is time to start planting the lettuces, spinach, etc.) and the herculean task it will take to clean spackle sanding dust from every corner of the house, if I didn’t get the warp on now, it wouldn’t get done. Complicating things is I agreed to house Natalie, because she is a good friend.

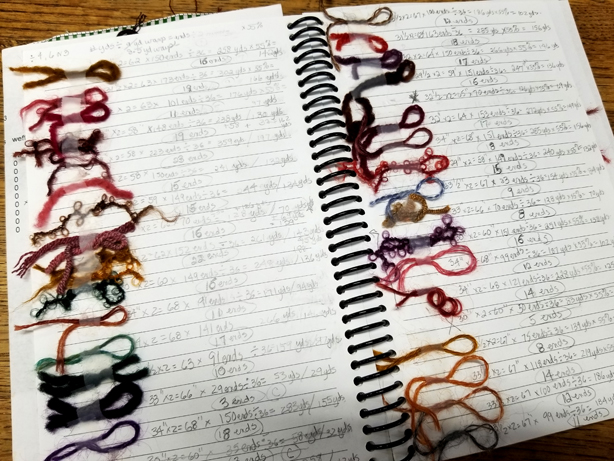

I didn’t have time to paint a warp, and I didn’t have exactly the yarn she suggested, but I have a lot of yarn. And I’m determined to use what I have. So I pulled some old vintage Contessa, a long discontinued yarn from Silk City Fibers, mostly rayon with a silk fleck, which I have lots of, especially hand dyed. It comes in at the same 2100 yds/lb as the 5/2 Tencel she suggested. Along with the solids, I have a few variegated cones, and though she specifically said no variegated yarns, I understood why, because she wanted the colors to line up, like it was hand painted. No problem as I know how to do this, and Contessa variegated was mostly engineered to repeat itself. I grabbed my music stand, wiped off the dust, and propped my little warping board onto it, and wound a circular warp, lining up the colors as I went.

I added the solid colors, a light, a dark, and a bright, and then went to the loom and started sleying.

And threading.

And now I have another warped loom, ready to go…

Meanwhile…

I decided, while I was trapped in my studio, with the animals, to finish up the 10 yards of 8/2 cotton I tied into my fall run of towels. I ran out of the light grey weft about a yard from the end, and grabbed a small cone of dark blue, which is gorgeous, but I didn’t have enough of the dark blue to weave the whole 10-yard run, and wanted to use up some of the various cones of light colors as weft.

Washed and dried.

Since I will be scrubbing everything I own in the coming weeks, I decided that the now cleared loom needed a good dusting and wipe down with Howard’s Feed and Wax. The loom is patiently waiting for my next adventure…

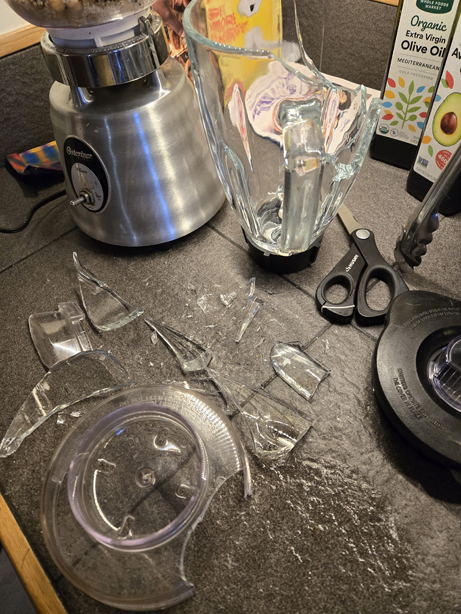

That night, making dinner, this happened. The blender bowl just slipped out of my hand, taking out the lid for my beloved mini Oster food processor…

By the time dinner finished cooking and I’d cleaned up all the glass, I had gone on Amazon and ordered replacements, which were there the next morning on my doorstep. The new mini food processor, my favorite tool in my kitchen is even better than the old one.

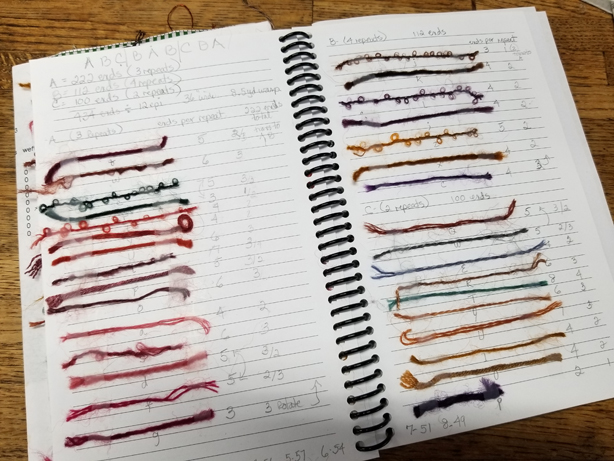

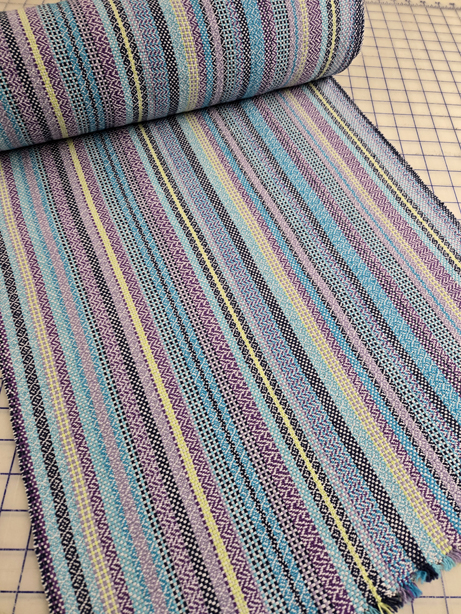

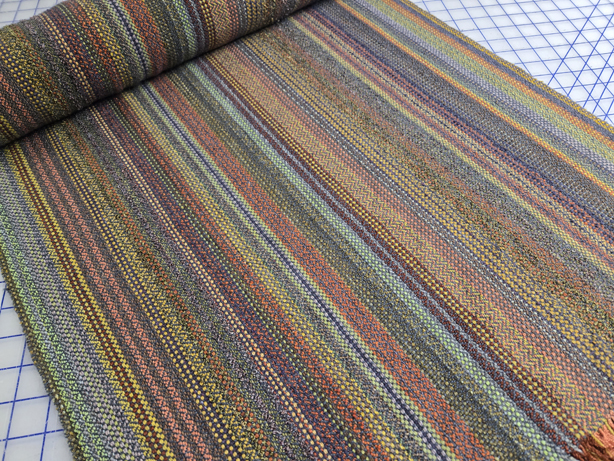

Meanwhile, I moved to another loom, that had 5 yards of hand-dyed warp in a four-shaft combination draft, the same draft actually, as the towels. I had just started the fabric last year, so the loom could sit in a corner of my retrospective at County College of Morris, to give viewers an idea of cloth on the loom. The weft was a medium grey alpaca/silk from Webs.

So I dove in, playing around with different shuttles to get the maximum speed, and resorted to my old favorite, my AVL end-feed, the smaller one. I flew through that yardage, periodically checking on the workers and tending to the animals who were at this point really confused… But mom, there might be someone in there who will pet me, or even better, feed me…

That fabric is off the loom, washed, dried and rolled onto a tube.

And I dusted and wiped down this loom as well, with my friend Howard’s Feed and Wax.

I spent all day yesterday scrubbing everything in the book case in the den, and the moldings, which are awaiting installation tomorrow. I scrubbed the tile floor. I set up the little bistro set I ordered from Wayfair, so I could sit at the table and have my breakfast and watch the sun come up. My little bit of heaven, with a lot of elbow grease.

The cat of course, my constant companion, seems to like our new set up. He can watch out the window while patiently waiting to lick my bowl after I have my morning yogurt and granola.

So tomorrow, all the reconstruction should be finished, window trim installed, ceiling fan, and my cleaned wool rug that has been in storage since the end of December. If I can get my daughter to wake up on her day off, I’ll see if she can help me move the piano in there. The cello is already moved, and I have all my recorders to bring in as well. There is music in many corners of the house which will all be moved into the bookcase. (Once I dust them…) I will have my music room with a view… the best lemonade I could have ever imagined…

Spring is coming, stay tuned…