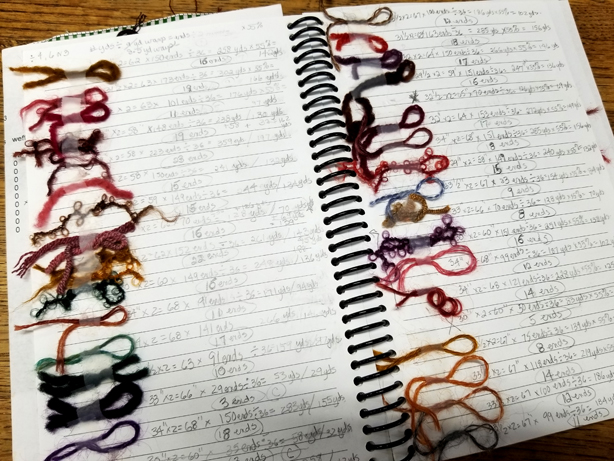

A couple of blog posts ago I mentioned I was embarking on one of those tedious, slow cloth kind of projects, that would use up almost three dozen various handdyed mixed skeins of wools, mohairs, and other mystery protein fibers. I did some furious mad calculations, a job that oddly appeals to me, and figured out how much was in each skein, and divided that into a 55%/45% split. I calculated I would use the larger amount for the warp, since there is loom waste, and the lesser amount for weft.

I did a similar project a few years ago, and really really enjoyed weaving it, even though I would be changing wefts something like every other pick. That coat from that plaid I wove will be in the next issue of Handwoven Magazine. Look for it…

Meanwhile, I realized that my original calculations were for a 36″ wide fabric, and the two larger 45″ looms were busy (my daughter commandeered them…). I have a 36″ wide Tools of the Trade, with 8 shafts, so I could spread the warp out over 8 shafts, even though it is a simple twill structure, to keep the warps from sticking to each other.

I calculated 12 ends per inch for the warp, but wanted to put two ends in a 6 dent reed, also to prevent sticking. I didn’t have a 6 dent reed for my 36″ loom. Sigh…

So I ordered a bunch of used reeds missing from my collection from my favorite place to purchase used weaving equipment. Oddly enough I’m a fan of older carbon steel reeds because the steel gauge is pretty substantial. Some of the new stainless steel reeds have a gauge that is too thin in my humble opinion… But I digress…

My favorite place to purchase used weaving equipment is Eugene Textile Center, in Oregon. I’m in NJ, so I knew I’d have to wait patiently for anything I ordered to cross the country. It came by pony express. Just kidding. The package of reeds, (I got a 5 dent while I was at it because you never know, plus some for a 32″ loom that I had acquired a couple years ago), was shipped FedEx Ground on April 19th. Watching the tracking was pretty hilarious. They went from Eugene, to Portland, to Seattle, to Montana, to North Dakota, to Illinois, to Ohio where they sat for a few days, to three stops in Pennsylvania, where they were delayed by some sort of mysterious weather, and then finally on to NJ where they arrived Thursday.

I wasted no time in sleying that 6 dent reed.

I threaded in record time, I mean 12 epi is nothing.

I beamed while teaching a remote three day workshop, I could watch the class on my laptop, and while they were busy working, I could quietly beam.

And then I tied on. I started weaving with some scrap wools I had just to check threading and sett, and I was definitely not happy. My immediate instinct is, “It should have been sett denser”, which is my main motto in life. The next size reed I had was an 8, which would put the sett at 16, and I didn’t want to go that dense. But by the stroke of luck, I had purchased a 5 dent, and three per dent works out to be 15 ends per inch.

So I resleyed the reed, and now my fabric, which used to be 36″ wide, is now about 29″ wide. That’s actually better because I plan to hand feed balls of weft across, I don’t want to juggle about 36 shuttles, and it is easier to reach with 29″ than 36″.

I started weaving and OMG it is perfect. It is exactly what I envisioned and I just absolutely love when that happens. The twill lines are at a 45 degree angle.

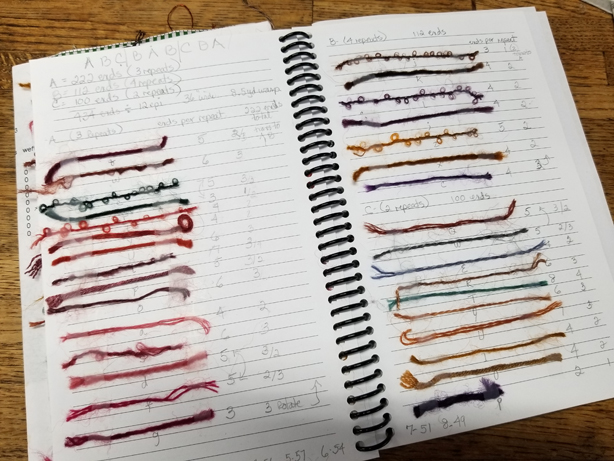

So the next step is to carefully plan out the treadling and the reverses and what yarn goes in what pick. There are almost 36 different wefts. And most are only used 1 or 2 times in the weft before changing. This will be very slow cloth.

I printed out the treadling (I’m splitting the shafts between two treadles for each pick so both halves of my body get equal exercise and to further enable the wools to separate easily while weaving.) Next to each treadle pick is a color that codes to a yarn, but some are so close in color I didn’t want to get confused, so I put small bits of the yarn with double faced tape with each weft pick.

I have little treadle notes taped all across the castle (that’s a loom part for you non weavers).

And I have two basket trays of balls, carefully placed in sequence order, so I can just draw the next one, glance at how many picks I need of it, and double check that I’m on the correct treadles. This will be really entertaining to weave. And slow. But I’m not in a hurry.

Meanwhile…

Because nothing in my life is ever boring…

I got a call last week, that a beloved friend, who had acquired a loom in very poor condition, decided that after a number of years, would never really be able to put in the time to get the loom up and running. I was with him when he acquired it, it is a lovely loom, a full size Macomber with 8 shafts, double warp beam, but only 24″ wide. It had originally been stored and nearly ruined in a screened in patio through a number of very wet and cold winters. It was missing a lot of the beam hardware, and was very very rusty and dirty. He sadly had not been able to do anything with the loom in all the years he stored it. So I adopted this loom.

Yeah, I know… This is number 36…

Though I’ve woven on Macomber looms since the 70’s, I never actually owned one. I rehabbed all the looms that we moved from William Paterson University to Peters Valley probably back in 2014, I know this loom well. And Macomber is still making looms, way up there in Maine, and they are really knowledgeable about the history of every loom they sell. This one apparently was part of a large order from 1970, built for Philadelphia College of Textiles. It has not fared well through the years.

So I put in an order for all the replacement parts I needed, and 800 new inserted eye heddles and a bench while I was at it, and $1000 later, hopefully it won’t take as long to tour the country as my poor reeds from Oregon.

Sunday a week ago, I got a bucket of Murphy’s Oil Soap, and scrubbed this poor child down, changing the blackened water after wiping down every beam. A very generous coat of Howard’s Feed and Wax was applied once it was dry.

I’ll tackle the shafts when I get the new heddles. There is a lot of rust, but I’m confident I can bring this loom back to its original glory. Can’t wait to get a warp on it.

So that’s my week, more to tell, but I’ll save it for another time. I wake up each morning ticking off an agenda of cool things to accomplish, including spending some time weeding the yard, something I’ve never been able to do on a regular basis with all the travel.

Carry on dear friends, I’ve got fabric to weave, looms to rehab, gardens to tend, and videos to produce. My life is full!

Stay tuned…