What an odd day. I had some very sad news this morning, after my celebration yesterday of my 7th anniversary of my cancer diagnosis, one of my very best friend’s was diagnosed with breast cancer. I’m so sad for her, this is such an epidemic, that I almost feel like it isn’t a matter of if, but when… The good news is that it is in a pretty early stage and with careful treatment it should all be fine. But that doesn’t help right now, you still have to go through the misery and fear of a diagnosis, not everyone responds to your news in the best most supportive way, and the road will be a thorny and uncomfortable one. But like I told her this morning, what ever side of the spiritual fence you sit on, I firmly believe that the universe sends angels, lots of them, to guide you through this maze, and they are always there in disguise, you just have to know they are there and look for them. The fiber community really rallied around me when I was diagnosed, I got some lovely cards, handwoven scarves, cookies in the mail from Connecticut, love and support through phone calls and emails. Oddly enough my favorite emails came from Duchess, a lovely black Labrador who had also just had a mastectomy and we corresponded through her owner for a couple of years. Oh, and I loved the email from some wonderful angel who said to me, “You can’t die, because I haven’t taken a workshop with you yet.” That might sound like an odd thing to say, but it gave me a good laugh and kept me going through another couple of chemo treatments, it lifted my spirits in a way that said, I was so much more than this disease and I wasn’t done here yet.

I also had a phone call which thrilled me, the rumor from a very reliable source, is that Pellon will eventually be printing the red dot plates onto a pattern medium they already had in the archives with seems to be identical to the base fabric of the original red dot tracer from HTCW, which has sadly been discontinued. If you haven’t followed this thread of the blog, I’ve been in hot pursuit of a suitable pattern tracing medium to replace the discontinued Red Dot Tracer, and it seems I only have to wait a bit longer. 🙂

I had to switch gears today, I wanted to send a piece to the members exhibit at the Surface Design Conference in Kansas City. The deadline is March 1st. I was under the assumption that they wanted an image by March 1st, but when I reread the prospectus, it calls for the actual piece, 18″ square to be sent to them by that date. I had been planning to use the photo of the 16″ version, and if accepted would weave the 18″ version. But alas, they need an actual piece.

So I brought my table loom over to the cutting table , which is really convenient because I can stand and cut the strips as I weave them in. The second or third blog I wrote back in December described the process and gave the draft, using a Theo Moorman threading. I weave about a quarter inch of ground fabric, then lay in on top a thin strip of silk, and hold it down with poly sewing thread which is warped in with the cotton ground. The strip is part of a childhood photograph I printed on 10mm silk Habotai, which comes on an 8.5″ x 10′ roll, pretreated for ink jet ink, and mounted on paper for easy transport through the printer. I got this from Dharma Trading. By running two lengths of this silk, 8.5″ x 16″ long, I could print a much larger image, since I’m stripping it anyway, it doesn’t matter if it is in two pieces.

So I brought my table loom over to the cutting table , which is really convenient because I can stand and cut the strips as I weave them in. The second or third blog I wrote back in December described the process and gave the draft, using a Theo Moorman threading. I weave about a quarter inch of ground fabric, then lay in on top a thin strip of silk, and hold it down with poly sewing thread which is warped in with the cotton ground. The strip is part of a childhood photograph I printed on 10mm silk Habotai, which comes on an 8.5″ x 10′ roll, pretreated for ink jet ink, and mounted on paper for easy transport through the printer. I got this from Dharma Trading. By running two lengths of this silk, 8.5″ x 16″ long, I could print a much larger image, since I’m stripping it anyway, it doesn’t matter if it is in two pieces.

In the first photo, I found if I score the paper backing with a sharp ruler edge, I can get it started easier than fumbling with the corner. In the second photo, I am peeling the paper backing off the silk. In the third photo, I am

In the first photo, I found if I score the paper backing with a sharp ruler edge, I can get it started easier than fumbling with the corner. In the second photo, I am peeling the paper backing off the silk. In the third photo, I am  cutting the strips of silk, I cut them about 3/16″. You can see there are two big sections that make up the image. The last photo is of the table loom, you can see I have two strips woven in already. I’ll describe more about the weaving process later. I figured out a way to do a pick up of the tie down threads so only the ones I need are actually held out, the rest on the side get woven into the ground.

cutting the strips of silk, I cut them about 3/16″. You can see there are two big sections that make up the image. The last photo is of the table loom, you can see I have two strips woven in already. I’ll describe more about the weaving process later. I figured out a way to do a pick up of the tie down threads so only the ones I need are actually held out, the rest on the side get woven into the ground.

This will be a slightly larger version of one I sold, called Big Sister. The photo is from around 1957, of my younger sister and me, caught in an intimate moment. The photo is the smaller version. In the December blog, I was weaving the same piece, but 24″ wide. My sister saw it on my blog and tearfully requested one for her, she even offered to pay me, but since she is the other child in the  photograph, it is only fair she gets this one once I have exhibited it.

photograph, it is only fair she gets this one once I have exhibited it.

At one point the room full of 18 year olds, emptied as they all went out side on the terrace, and the couple of us there over the age of 40 (over 50 for me) took full advantage of the DJ, dancing like we were 18 again, to things like ABBA’s Dancing Queen. Even my mom at 78 got in there, saying, “If Meryl Streep can do it, so can I!”

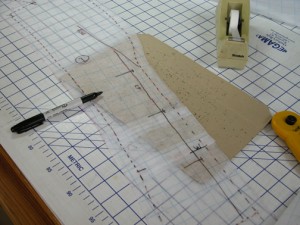

At one point the room full of 18 year olds, emptied as they all went out side on the terrace, and the couple of us there over the age of 40 (over 50 for me) took full advantage of the DJ, dancing like we were 18 again, to things like ABBA’s Dancing Queen. Even my mom at 78 got in there, saying, “If Meryl Streep can do it, so can I!” Lots of email today, lots to answer, spent awhile at the shipper getting everything in order to head to California ahead of me. Once I finally plowed through all that stuff, I got to do what I really wanted to do, which was make progress on the jacket. First I had to alter all the pieces to lengthen the waist, so I spliced in some additional pattern paper, and because my original pencil lines were fading, I traced everything again with a black sharpie. I used a hunk of cardboard underneath because the pattern medium is so porous that the ink bleeds right through all over my rotary cutting board. I had to respace the buttons as well.

Lots of email today, lots to answer, spent awhile at the shipper getting everything in order to head to California ahead of me. Once I finally plowed through all that stuff, I got to do what I really wanted to do, which was make progress on the jacket. First I had to alter all the pieces to lengthen the waist, so I spliced in some additional pattern paper, and because my original pencil lines were fading, I traced everything again with a black sharpie. I used a hunk of cardboard underneath because the pattern medium is so porous that the ink bleeds right through all over my rotary cutting board. I had to respace the buttons as well. The next step was to layout the pieces to make sure I would have enough fabric. I ALWAYS cut handwoven fabric singly, you only have to try it once doubled to know that no matter how accurate you are, the underneath layer will be a couple grainlines off and then the whole left or right side of the garment will be off as well. So I carefully layout everything, remembering to flip when I cut the opposite piece. It was pretty clear I would have plenty of fabric, and then some (maybe enough to squeak out a little pencil skirt?)

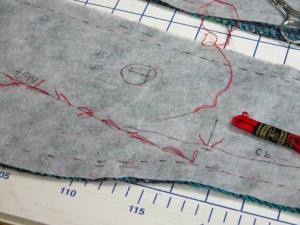

The next step was to layout the pieces to make sure I would have enough fabric. I ALWAYS cut handwoven fabric singly, you only have to try it once doubled to know that no matter how accurate you are, the underneath layer will be a couple grainlines off and then the whole left or right side of the garment will be off as well. So I carefully layout everything, remembering to flip when I cut the opposite piece. It was pretty clear I would have plenty of fabric, and then some (maybe enough to squeak out a little pencil skirt?) There are a lot of pieces in this jacket. Before I removed each pattern piece to flip for the other half, I transferred the marks with tailors tacks, which need only be one pass through since the fabric is single. I learned a trick when I was teaching in Colorado, to use a single strand of six strand embroidery floss as the tailor tack thread instead of sewing thread which is really smooth and falls out easily. The floss is spun in a way that it stays put much better.

There are a lot of pieces in this jacket. Before I removed each pattern piece to flip for the other half, I transferred the marks with tailors tacks, which need only be one pass through since the fabric is single. I learned a trick when I was teaching in Colorado, to use a single strand of six strand embroidery floss as the tailor tack thread instead of sewing thread which is really smooth and falls out easily. The floss is spun in a way that it stays put much better. In one area, the collar/front piece, which is a cut four, because the whole thing acts as a facing as well, was a fraction too wide for the fabric. So I did my quick trick of taking a hunk of selvedge from another area, and whipping it together with the other selvedge, and violá, instant wider fabric! Handwoven selvedges are really easy to butt, and they are really invisible unless you have messy selvedges.

In one area, the collar/front piece, which is a cut four, because the whole thing acts as a facing as well, was a fraction too wide for the fabric. So I did my quick trick of taking a hunk of selvedge from another area, and whipping it together with the other selvedge, and violá, instant wider fabric! Handwoven selvedges are really easy to butt, and they are really invisible unless you have messy selvedges. I still have to cut the lining and the interfacing, I’ll interface the entire garment with a fusible, which one I’m not sure since I still have to test on some scraps, but I assembled all the elements I have so far for the jacket. I found a half yard of navy blue Ultrasuede that I’ll use for the lips of the bound buttonholes, and the welt pockets, and I have tons of floss in the same color as the felt belt I want to cut up for piping, in case I decide to couch some details.

I still have to cut the lining and the interfacing, I’ll interface the entire garment with a fusible, which one I’m not sure since I still have to test on some scraps, but I assembled all the elements I have so far for the jacket. I found a half yard of navy blue Ultrasuede that I’ll use for the lips of the bound buttonholes, and the welt pockets, and I have tons of floss in the same color as the felt belt I want to cut up for piping, in case I decide to couch some details. Thanks for all your great comments about the lines of the felt/piping, I should say that I am rather embarassed, I got so carried away in Photoshop I failed to notice that the princess lines come from the shoulder, not the middle of the sleeve, so in fact the piping line comes straight over the shoulder and I think will give a great line to the jacket. It is one of those things that I won’t know until I actually sew the thing, worst case is I hate it and take it apart. You can do that with sewing. I do it a lot…

Thanks for all your great comments about the lines of the felt/piping, I should say that I am rather embarassed, I got so carried away in Photoshop I failed to notice that the princess lines come from the shoulder, not the middle of the sleeve, so in fact the piping line comes straight over the shoulder and I think will give a great line to the jacket. It is one of those things that I won’t know until I actually sew the thing, worst case is I hate it and take it apart. You can do that with sewing. I do it a lot…

warping paddle will be demonstrated. This device allows the weaver to chain warp up to 24 ends at a time. Calculating warps for repeats will also be covered if time permits.

warping paddle will be demonstrated. This device allows the weaver to chain warp up to 24 ends at a time. Calculating warps for repeats will also be covered if time permits.