Grab a cup of tea, or your liquid of choice (go for the wine) and grab a seat, it is going to be a long one.

So much for retirement! If these last couple weeks have been any indication, I’m toast! Almost all of the events of the last couple weeks have been ones I chose, ones I intentionally put on the calendar, and I don’t have a single regret. But I’ve worked hard…

At the end of August, shifted by a few days for a scheduling conflict with one of the students, I had a couple of, I really can’t call them students as they are at this point old friends, come for a five day retreat to sew their pile of patterns, and garments from their handwoven cloth. These are friends who have studied with me for years at one of my regular venues. They immediately found the part of my property where they loved to sit and rock and have wine at 5 o’clock. Friends help me find new ways to enjoy what I have, in the studio, in my yard, and in my house.

They came with an agenda, and I’m happy to report that they accomplished everything they had on the list, and then some.

One of the students brought pieces from a handwoven coat, she had made years ago and never liked, and using my 1800 zippered jacket pattern, created this variation. I’m always thrilled when I or one of my students repurposes.

This student brought a dress from commercial fabric she made on her own, but didn’t like the way it fit. We were able to take up the whole dress from the shoulders creating a more attractive neck. The pattern is from Merchant and Mills, the Dress Shirt

She also tackled a piece of loosely woven handwoven fabric, which we saved by using a fusible underlining to create the start of a dress, The Augusta Dress from Grainline Studio. She is experienced enough at this point to finish the dress on her own. It was a complicated asymmetrical neckline, but she pulled it off.

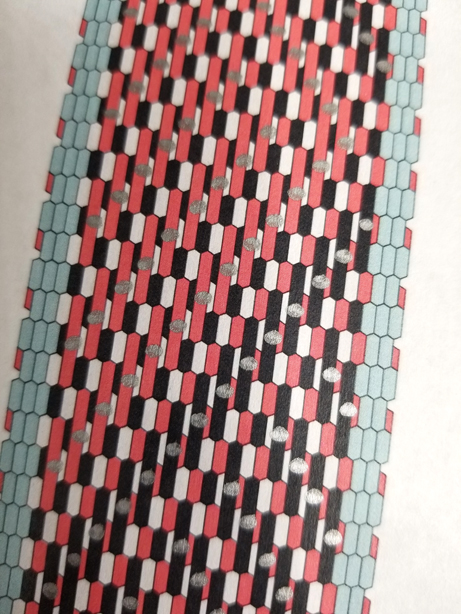

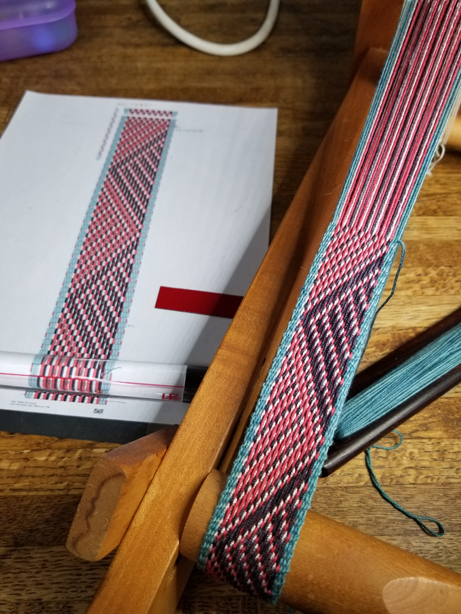

The other student started with a handwoven fabric from her stash of Zephyr Wool and Silk from Jaggerspun. She created my 200 Jacket with a shawl collar, and used this wickedly cool silk lining she had in her stash. And she spent the first day learning to insert a perfectly matched welt pocket.

She also fitted and sewed up a really cute summer cotton top from a crinkle fabric she had in her stash. The pattern is from Simplicity D0676.

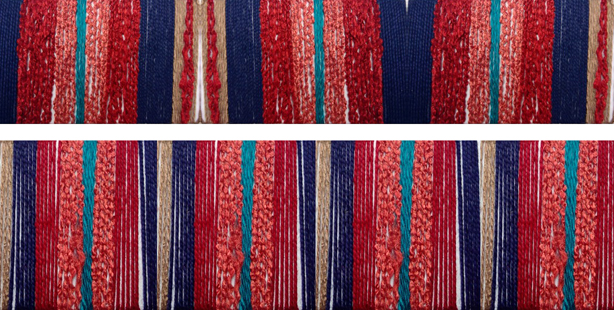

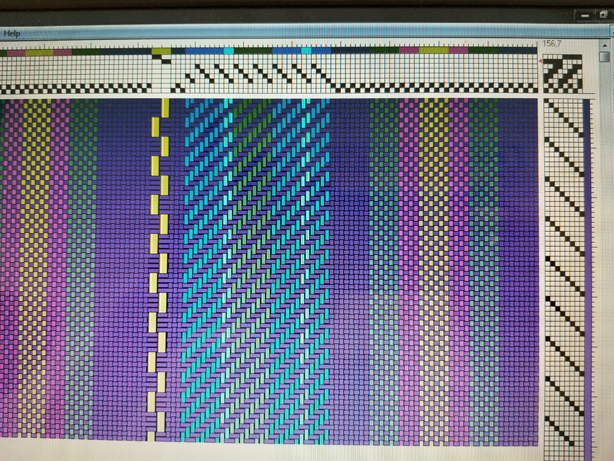

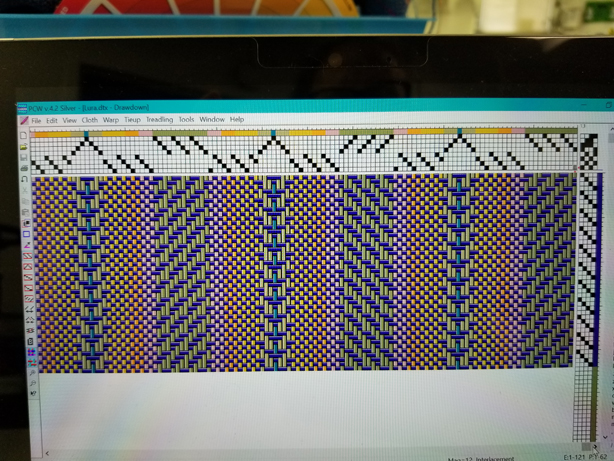

And then she copied my 1000 swing dress, with the A-line variation, something I cover in my YouTube Videos, The Weaver Sews. I think it was the episode on Combining patterns. She had a length of handwoven fabric she had woven a few years ago, and decided that everyone needs a brightly striped dress for the summer!

So mid week, we had another visitor named Ida. This visitor wasn’t part of the agreement and was definitely not welcomed. My sewing studio is in the basement, and through the years I/we took steps to mitigate water issues, new gutters, a sump pump, and a replaced retaining wall under the front stoop, keeping water running off the street in an exceptional situation from entering the foundation. This is a 100 + year old house with poured concrete over a dirt cellar floor. There are cracks and in the boiler room where we ripped out the old oil, converted from coal furnace back in the 80’s, there are even holes going down to the dirt. The floor is porous, but I rarely have issues. I did design the studio just in case, to accommodate a bit of water, just in case.

So Wednesday night Ida came to visit, wrecking havoc in NJ and NY, and of course all the states in its path. When we moved here in the 80’s we knew that more than half the town was in the flood plain, but we were up on the hill, so we knew we wouldn’t be flooded at least by the river. We have watched our neighbors in the flood areas of town lose everything many times over the years since we have been here. It is always devastating to see. The flooding here was catastrophic. Because I am higher up, river flooding isn’t an issue, but 10″ of rain in four hours is too much for the storm drains coming off the hill, and if it hadn’t been a hurricane and dark outside, I would have loved to have stood in the street and watched rivers of water come cascading down my street, jump the asphalt curb and run right into the front wall of the foundation.

I would have been teaching up at Harrisville this week had I not chosen to retire. And had I not had students, I wouldn’t have been in the studio late to turn things off and move a few pieces of sensitive equipment like sewing machines off the floor, just in case. The sump pump was happily humming along, so I was pretty confident I’d be OK. I turned to walk down the little hallway in front of the boiler room, which is walled off, to head upstairs and I was horrified to step on a mat with water squishing out everywhere. I yelled for my daughter, and thus began our evening, finding every towel in the house, because, yeah, we had a mess. We opened the door to the boiler room and were appalled to see water just pouring in the front wall of the foundation and actually seeping up through the floor. I stood looking at the water and said to my daughter, what did we have in the house that could suck up water, because I had given away my shop vacs, as I didn’t need them and needed the garage storage space for my 39 shaft looms. She looked at me, without batting an eye and said, “A Turkey Baster”.

For the next four hours, I sat on a stool, after channeling the water into the holes in the floor, sucking up quarts of water into yogurt containers, and Pyrex glass ware from my dye studio, while she hauled wet towels to the upstairs laundry and dumped the containers of water. All the dry concrete in front of me had been covered in water, so this was no easy feat. I’m glad I’m a textile artist with a lot of bath and beach towels.

We won. I’ve never been so tired in my life. When the rain stopped at 2:30 in the morning, the water stopped entering the basement, and I took a load of newly washed and dried towels and covered the area and went to bed. Class started again in a few hours and teachers gotta do what they gotta do… My students slept not knowing what was happening two floors below. I’m grateful I was home, I’m grateful my daughter was here, I’m grateful for a lot of towels, I’m grateful we never lost power, and I want to bronze that turkey baster and frame it as a reminder that sometimes the simplest thing can save the day. I will though, buy a new one for the kitchen, should I ever need to baste a turkey.

My students left on Friday night, and early Saturday morning I headed out to Peters Valley School of Craft for a five day basket making class using foraged materials. Because Peters Valley sits in a National Park Recreation Area, we weren’t allowed to forage for the actual materials, but the teacher Steven Carty, brought a van load of materials, bark, vines, tools, and everything we needed to create baskets from stuff found in the wild. (Note: they have closed the physical shop, but maintain a Facebook presence and have mail order basketry supplies available.)

My purpose in taking the class was to begin to identify what I had in my yard, what could be a basket making material, how to harvest it, store it and actually use it. I found out pretty quickly that almost everything out there is usable. I have to have a talk with my yard guy since I mostly pay him to rip out invasives, but now I need to harvest them and I have a lifetime of materials right out my door.

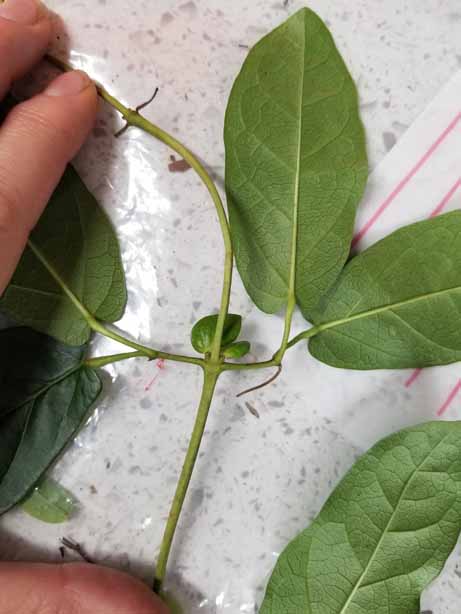

I discovered I had vines that I never planted, Bittersweet, and Akebia, and this one that has just the coolest leaf structure called Crossvine.

Anyway, we started with a simple garlic basket from rattan so we could learn to twine, and then he showed us how to make cordage. Which is something I always wanted to learn. I made a lot of cordage stripping the bark off wisteria runners.

Day 2, I made a basket with Arborvitae bark staves and wisteria runners, the bottom tier had the bark stripped which I twisted into cordage. The top tier has the vine with the bark intact. The rim is cedar bark and the lashing wisteria bark from the runners.

Day 3 we learned how to create a bark basket, scoring the bark so it folds into a container shape. This is pretty cool, but I don’t see myself traipsing around the woods looking to fell young hickory or tulip poplar trees. I don’t want to work that hard in my old age. We scraped the bark from cedar strips and used it for the lashing.

I spent the morning of Day 4 researching what was in my yard. I brought a few samples of the vines from my yard, and used his reference books and a couple of phone apps and Google to help identify what I had. So I started this basket, using more of the tulip poplar strips as staves, and started twining my vines, still green, so a bit fragile, because I wanted to see how they worked and how they dried. I started with the bittersweet at the very bottom, used trumpet vine, which was pretty fragile at the joints, and ended with the Akebia 5 leaf, also called Chocolate vine. That was great to work with green. I added a cedar rim, and that night I challenged my daughter to figure out how to end the staves, and she slit them lengthwise and braided them into an interesting top rim. The afternoon of Day 5 I made a few yards of fine cordage from Dog Bane, also called Indian Hemp, which I then used to lash everything together.

My daughter had assisted this instructor back in 2019 for a basket making class when she was the fibers assistant at Peters Valley. She loved making baskets and was really jealous that I took his class, and pumped me for information each evening when I came home. I saved some of the lashing work to do at home and I had lots of help from the cat. He happily stirred the soaking water for me. I didn’t have the heart to tell him that wasn’t necessary.

The morning of the 5th day, the class when on a nature hike through areas of Peters Valley, protected of course because it is federal property, and Steve showed us all kinds of flora and fauna, edibles, plants for dye stuff, vines, invasives, and I thought he would have a heart attack when he found a lone hemlock tree. Gave a new meaning to the word Tree-Hugger. Our goal was to reach a rock formation I did not know existed, dating back centuries, hidden in a part of the Valley off the road to the Thunder Mountain studios. It is called Bevans Rock Shelter, and there are even traces of early ochre paintings.

We took a class photo with our baskets.

When I got home last night, Brianna had already begun to harvest stuff from the yard. We rigged up a storage system in the garage studio, for some of the wisteria and English Ivy vine I brought home from class. I long ago committed chemical warfare on the wisteria that had invaded our property in the 80’s. This morning she went out and harvested more bittersweet and some really out of control rose runners that I swear grow 6 feet overnight. She can’t wait to tackle the gazebo.

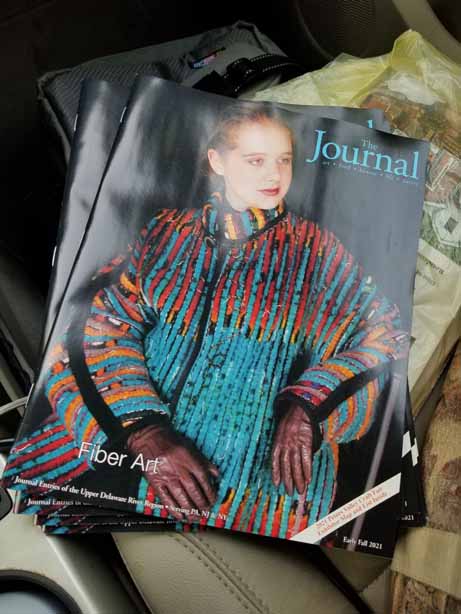

The first morning of class, when I stopped to check in at the office, Jen the person who keeps the Valley humming along, excitedly pulled a handful of magazines out of a box that had just come in, a free publication for the tri-state area (NJ, NY, PA) called the Journal. It had just been delivered the day before, and there I was, or rather my daughter, wearing one of my handwoven coats from a number of years ago. My daughter modeled for me when she was something like 11 or 12. She is now 28. The publisher of the journal had reached out to me a month or so ago, and asked for a piece on creativity, tied into Peters Valley, and what it was like to be a fiber artist, and for lots of pictures of my work. I was hesitant at first, I live in a different county, and I’m no longer teaching on the road or selling my work, but she insisted that I had a story to tell, and they wanted to publish it. The issue is full of images of my most colorful work over the years, and my daughter is beside herself that she made a cover, even though she was only 12 at the time. You can read the early Fall issue of The Journal here.

And so, I actually get to take a mini vacation, I’m heading down the shore Saturday morning with my sisters for a three-day getaway, which I sorely need, and Brianna will hold down the fort and be with the animals. All seems to be quiet in the Atlantic, let’s hope it stays that way.

Stay tuned…