It is a challenging world we are living in right now. It is hard to know what to make of things, what to focus on, where I can do the greatest good. Living in the moment, taking each thing as it comes, putting out small fires, and taking pride in the smallest of endeavors keeps me moving in a forward direction.

Earlier in the week, I had my landscape designer come back with her helper, to remove more Burning Bush (Winged euonymus) from the property. A couple of them were probably 15 feet tall, been in since the 1980’s. She doesn’t use heavy equipment, just a shovel, loping shears, a hand saw, and a pick ax. They are a remarkable team.

She removed all the branches from the four bushes, and her helper set out removing the stumps. To watch someone with that kind of physical strength and determination was really powerful. I wish a bit of that for all of us. When Saul finally got the root system to break free, the look on his face was indescribable. I asked him if he was proud of what he had done, and he responded with such joy, how he lives for this kind of personal triumph. Of course then he proceeded to spend the next hour with a pick ax and a hand saw, taking apart the root ball so they could lift it in parts and get it in the back of the truck with all the branches and the other root balls. I wanted to genuflect at the greatness of perseverance.

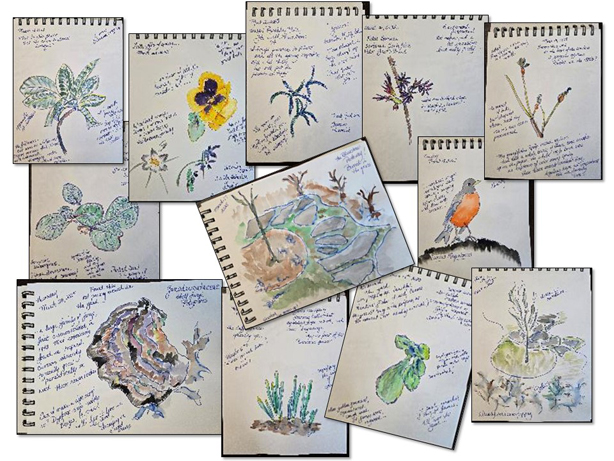

I thought about my own life and what things, no matter how small, gave me a sense of personal triumph. No one may even know, no one may even appreciate some of the things that I do on a daily basis that give me real satisfaction. But nevertheless, I managed to do something I didn’t think I could do, or was really challenging, and I managed to pull it off, and those are the things that make us smile and pat ourselves on our own backs and say, well done.

Even when we aren’t even sure what we did to make something happen, against all odds there are five adult frogs living in my ponds. I haven’t had frogs in my ponds in years, frogs are one of the things struggling to survive in these changing environments. But there, sunning itself, was a gorgeous frog, and when my pond guy came and opened up the ponds, cleaned them out and hooked up the filters, he found five. I’m not sure how they found me, but they are most welcome.

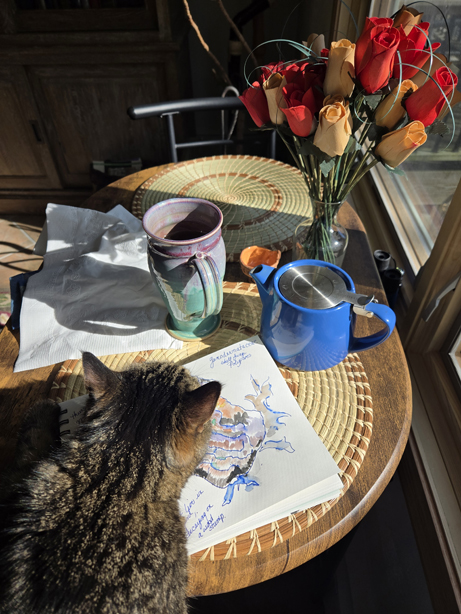

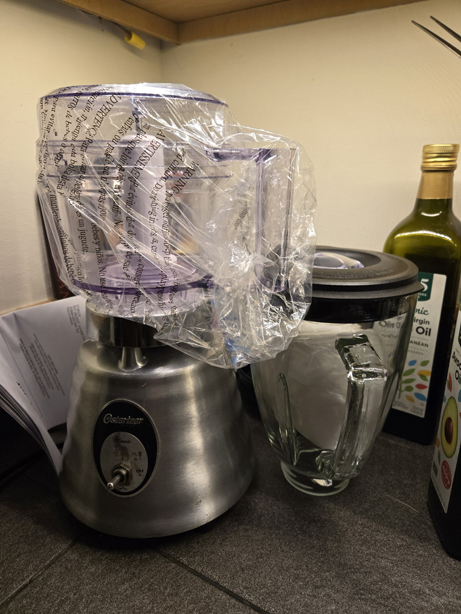

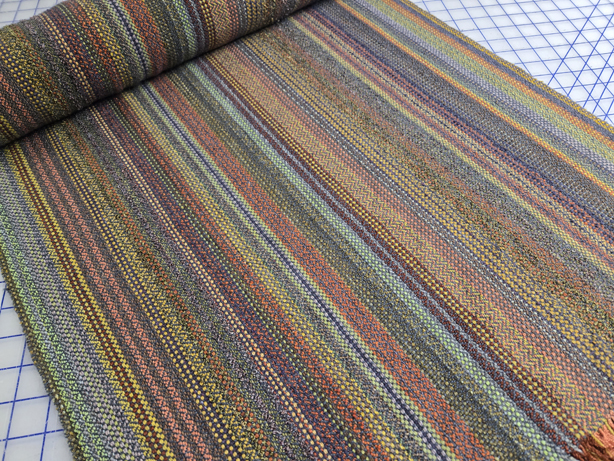

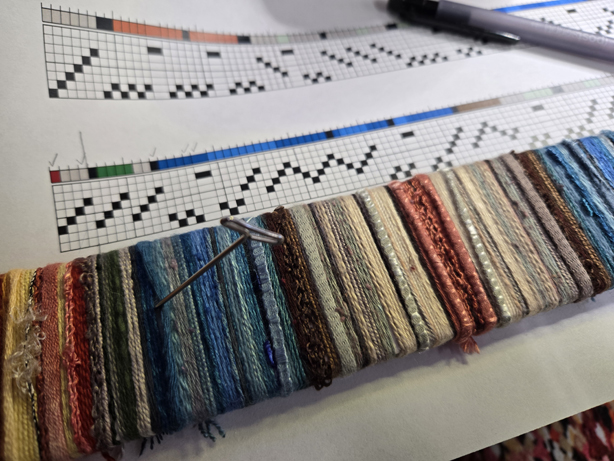

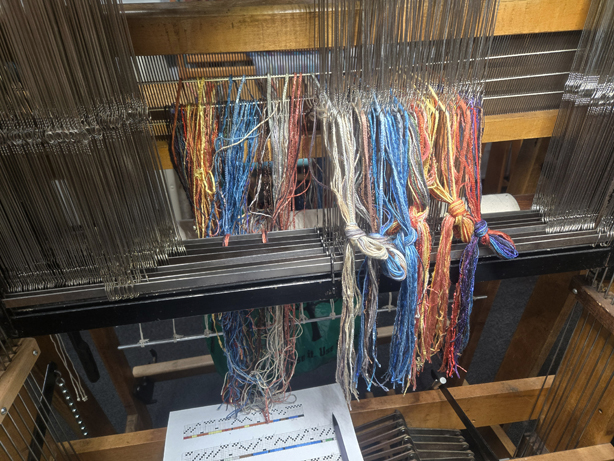

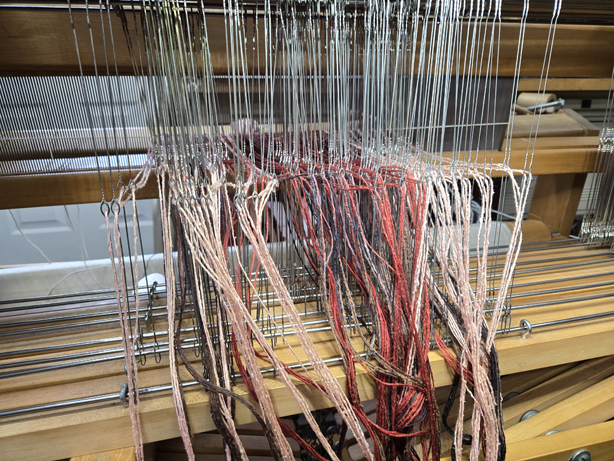

I’ve had a house full the last couple of weeks. Natalie Drummond was here last weekend for a workshop with my guild. I adore Natalie, I’ve known her since she took one of my retreats in the Outer Banks, NC back in 2018. I’ve followed her career. She has made Deflected Double Weave her thing, (that’s a structure in handweaving), and we all arrived at the 2 1/2 day workshop with looms warped and ready to go. I blogged about setting up the loom last month, knowing this past couple of weeks would be challenging.

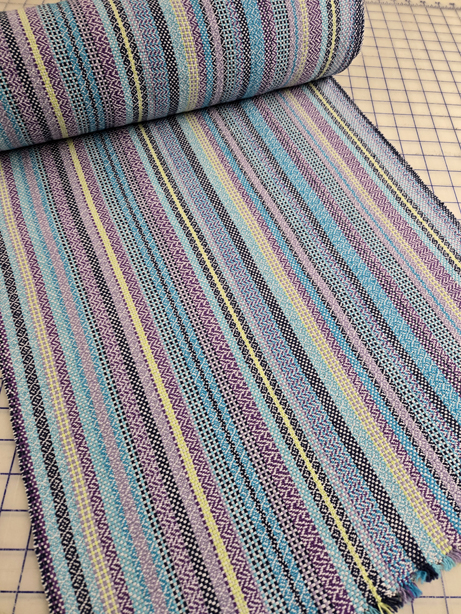

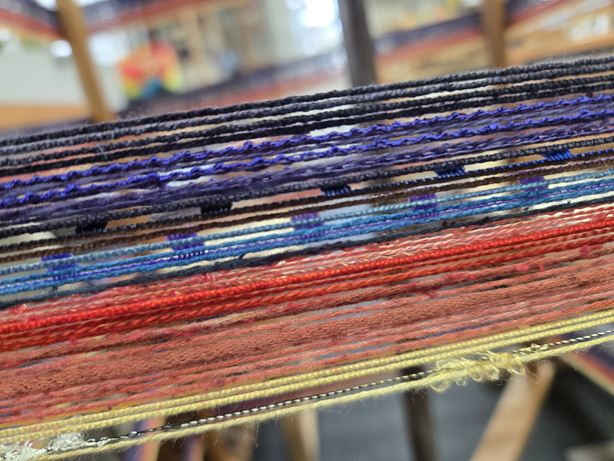

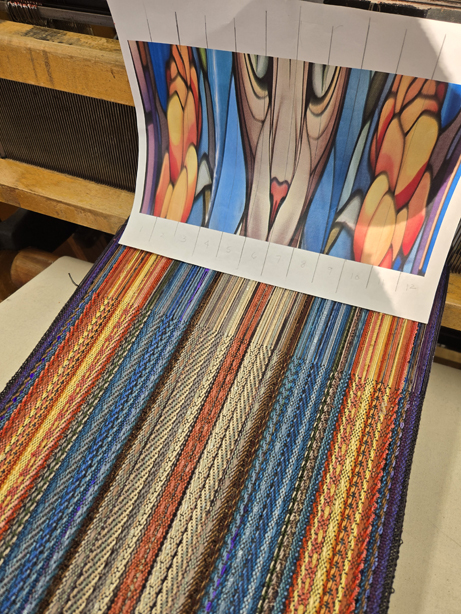

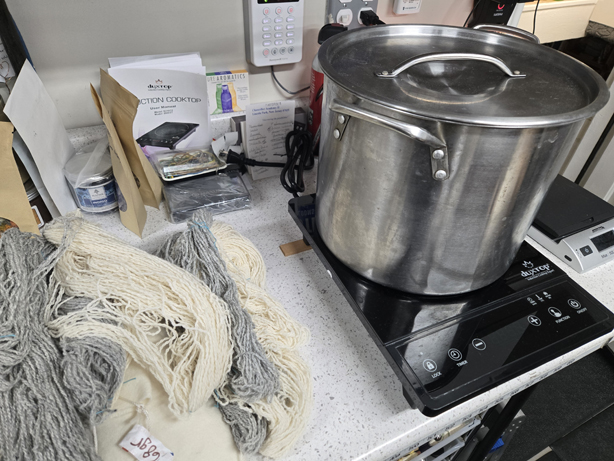

Natalie encourages the use of hand painted warps, I chose to use a variegated yarn wound circular to create an ombré effect. I was fine with it. One of the things she teaches is how to substitute a warp, or group of warps if you want to change things up. My warp didn’t really lend itself to that, I liked the value contrast in what I had, but I followed along, always willing to learn something new. We used a lot of cell phone camera previews, checking value by using a grey scale mode.

There were two of us who picked one of the eight shaft pattern samplers, and I started in on the sampler the morning of the second day. I happily sat and did my thing, making sure Natalie was fed (since I was the hostess) and by the end of the day, I had woven all three samples and an additional one, the last two were yarns that would shrink differentially.

We were then supposed to cut them off and wash them that night, and bring them back to class the next day to evaluate.

What surprised me was how much I loved the subtleness and patterning of the second sample from the bottom. I wanted to weave a couple of scarves out of that.

Once I was home, I had gardening and yard stuff to attend to, but alas, it was pouring rain all day, and so I decided to pull the remaining four yards or so from the table loom, because we have already discussed how much I don’t like working on a table loom, and put the whole thing on one of my floor looms.

Which I did. By the end of that rainy Monday, I was weaving away on my first scarf. The yarn, in case anyone is interested, is vintage Contessa, rayon and silk, from Silk City Fibers. No longer available (I’m still in mourning) I hoard whatever I can find at weaver’s estate sales. I have a lot of it I’ve dyed. I love the matte finish of this particular rayon with a silk fleck. Deflected Double Weave will deflect and collapse once it is washed, so the patterning will look quite different. And when I transferred the warp to the floor loom, I brought back in the original warps I had substituted out. I’m very proud of myself…

Meanwhile, after all this rain, my lawn was looking seriously like it needed mowing. Last Wednesday, after having decided not to renew the contract for my lawn service, I dug out the electric mower, made sure the batteries were charged, so I could mow. I couldn’t even find the batteries in the trashed wood shop from the racoon debacle. They had fallen under the workbench.

I got everything charged and set out to mow, and alas, I couldn’t get the poor mower started. I loved that little electric mower my husband bought me before he died. It worked last year, when against all odds, before my lawn guys came, I charged it up and was out mowing with a broken foot in a boot. Talk about proud of myself.

But this year. Nothing… So I spent some time looking at options on the internet, and ordered basically the same mower from Amazon, which arrived on my doorstep the next day.

The house guests I have this week, and old college friend and her husband in from CA for a family event, have been wonderful to visit with, and spend the evenings fixing puzzles, restringing my guitar, and going out to dinner. Her husband agreed to help me assemble the lawn mower, which I will admit, I would have probably had trouble doing on my own. I charged up the battery, and of course it rained. Three quarters of an inch, all day yesterday.

So today, after reading the directions for starting the new mower, I went to the old mower, which had been sitting out in the rain, and I tried it one more time before tossing it out at the curb for bulk pick up tomorrow, and to my complete shock, it started right up. Of course… So I mowed the back lawn. It performed admirably. I wasn’t going to return the new one, I’d already taken it out of the packaging and set it up, and so I mowed the front with that one. It is a little heavier and blows the grass out the side, so I have to learn the best way to use that feature. I don’t bag my grass.

Anyway, my lawn is mowed, and I’m pretty damn proud of myself.

Stay tuned…