It’s been years since I got ready for a show. I did craft fairs for ten years, that was a long time ago, and I’ve blogged ad nauseum about how I never wanted to sell my work again, and how I’m trying to overcome my need to hold on to everything I make, and how I might need it as a teaching tool, and well I could waste the whole blog on all my woes about my years of selling and how burned out I got.

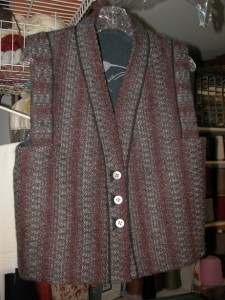

So fast forward… I have too much stuff I’ve made, and no where to put it. The airlines are restricting my luggage so badly, that I have to basically travel with nothing when I teach, and all these wonderful teaching pieces are now in photos and in PowerPoint presentations. I don’t wear most of what I make, or I wear it once for a fashion show, and exhibit it a few times, and that’s it. The pieces sit in cleaner bags in my closet, taking up valuable space. (I actually don’t have the lifestyle to wear and use all of what I make…)

So, with a critical eye, I’ve started to gather pieces that I think I might actually want to part with if someone really wanted to buy them. I’m not convinced that will ever happen, someone wanting to buy something I made isn’t something I’ve come to grips with, largely because a) I’m not in production anymore, I’m not buying in bulk and raw materials are expensive, b)I’m not interesting in making things in an inexpensive way, if I want to spend two days carefully edging the binding on a tote bag with couched yarn, well I’m gonna do that. Too bad if the tote is $300. c) I’m personally too cheap to buy anything that isn’t on sale for 50% off the lowest sale price or I have a 30% coupon at Kohl’s. I wouldn’t buy my work (because it is too expensive) so it is odd to me that anyone else might…

But I digress. This isn’t about selling my work, it is about making the commitment to tag and bring my work to the guild sale. In order to do that, I have to properly photograph everything I’ve done recently that hasn’t already been properly photographed. Blog shots don’t count. Because if I actually did manage to find someone who wanted one of my pieces badly enough to pay good money for it, I’d never see it again, and if I don’t have a proper photo of it, I can’t even use it for a teaching tool. In my “Photographing Your Work” Monograph, I believe the first slide in the presentation says,

Today is photographing day, which means I try to take my tiny weaving studio and turn it into a tiny photography studio, and since I’m doing small things, I need the table top set up, which means there is shit stuff all over the place. 🙂 It is really hard for me to work in this chaos, which is why I am blogging at the moment and not photographing like I should be, because I needed to just look at a computer screen for 45 minutes and not my studio.

Today is photographing day, which means I try to take my tiny weaving studio and turn it into a tiny photography studio, and since I’m doing small things, I need the table top set up, which means there is shit stuff all over the place. 🙂 It is really hard for me to work in this chaos, which is why I am blogging at the moment and not photographing like I should be, because I needed to just look at a computer screen for 45 minutes and not my studio.

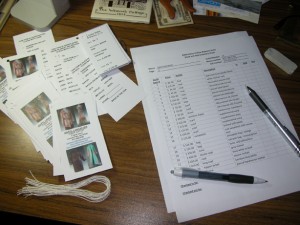

Once I’ve gotten a good photo of the piece, I carefully tag it with my own labels, and the inventory tag, and then bag it into one of those very large, no, jumbo, Ziploc see- thru bags with handles, that every fiber enthusiast on the planet has purchased by the industrial case!

Once I’ve gotten a good photo of the piece, I carefully tag it with my own labels, and the inventory tag, and then bag it into one of those very large, no, jumbo, Ziploc see- thru bags with handles, that every fiber enthusiast on the planet has purchased by the industrial case!

measure the heddles in the warehouse, and it looks like they might work. So I ordered 400. They were shipped today and I should be able to play with them next week. However, the remaining

measure the heddles in the warehouse, and it looks like they might work. So I ordered 400. They were shipped today and I should be able to play with them next week. However, the remaining  parts I have from the two Structo looms I started with are not enough to make a second loom. Specifically I’m missing the rods that hold the beater assembly together. They are small rods, with threads at the ends to hold a wing nut or a bolt at each end.

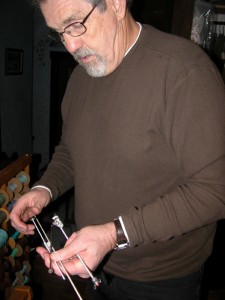

parts I have from the two Structo looms I started with are not enough to make a second loom. Specifically I’m missing the rods that hold the beater assembly together. They are small rods, with threads at the ends to hold a wing nut or a bolt at each end. Me: “I tried using my 20 year old shuttle with 10/2 tencel which is too fine for the tension the way it is set, and I found the original allen wrench that came with the shuttle, (be impressed, it has been in storage for 20 years and I put my finger on it in 45 seconds) and alas, the shuttle is actually defective. The whole thread carrying mechanism wasn’t installed right, because the set screw for the allen wrench is off just enough that the allen wrench doesn’t engage when you stick it in the little hole. I can’t return a shuttle that is 20 years old and this is the first I’ve noticed the problem…”

Me: “I tried using my 20 year old shuttle with 10/2 tencel which is too fine for the tension the way it is set, and I found the original allen wrench that came with the shuttle, (be impressed, it has been in storage for 20 years and I put my finger on it in 45 seconds) and alas, the shuttle is actually defective. The whole thread carrying mechanism wasn’t installed right, because the set screw for the allen wrench is off just enough that the allen wrench doesn’t engage when you stick it in the little hole. I can’t return a shuttle that is 20 years old and this is the first I’ve noticed the problem…” He takes the shuttle and looks in the light and verifies what I’m talking about. I felt sort of smug that he couldn’t fix it either. Then he turns the shuttle over to the back side and sticks the allen wrench in the rear hole, which I failed to notice was there, having owned the shuttle for 20 years, and he adjusts the tension.

He takes the shuttle and looks in the light and verifies what I’m talking about. I felt sort of smug that he couldn’t fix it either. Then he turns the shuttle over to the back side and sticks the allen wrench in the rear hole, which I failed to notice was there, having owned the shuttle for 20 years, and he adjusts the tension. Back to the Structo. So, now my husband looks at the rod I need for the Structo repair, and says, oh, you can get a rod that is threaded the entire length and then you can just cut it to the length you need. And he disappears.

Back to the Structo. So, now my husband looks at the rod I need for the Structo repair, and says, oh, you can get a rod that is threaded the entire length and then you can just cut it to the length you need. And he disappears.