My dearest friend Ginnie says that things you put off get bigger than they really are. I completely identify with this…

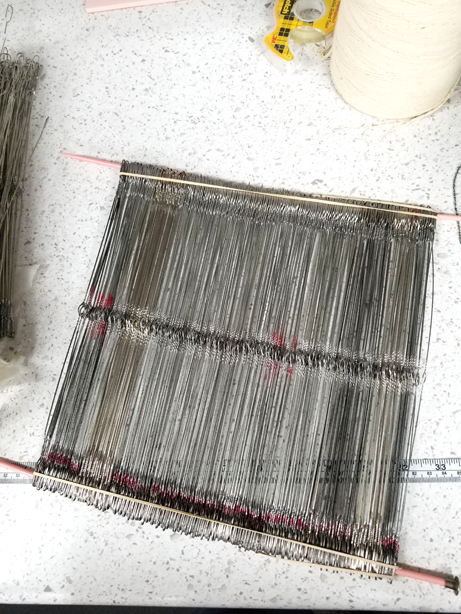

Back in October of 2019, in a particularly hellious month of stuff happening, I warped a loom and gathered stuff and headed off to my weaving guild for a three day workshop with Deb Silver, who exploded onto the scene with a very cool technique called Split Shed Weaving.

I actually loved the workshop, and thought the technique was brilliant, and her interpretation of it and what she did with it and how she conducted the workshop were all absolutely brilliant. I actually talked all about the works in a blog post back in October of 2019, you can read about it here, but you’ll have to scroll pretty far down because that month was so full of stuff I’m thinking the blog went on for pages… (I actually cringe when I read some of my past blogs and realize how out of my control my life was most of the time.)

I was in the middle of what I thought was a pretty cool sample when the workshop ended, no problem, I’ll just pick it up when I get home…

Hahahahahah!

I think I left the next day for parts unknown, and when I got back, we started the plans for the possible studio rennovation. The looms got packed, yarn and books and shuttles and tools all got packed up and moved, shelving units were relocated, and the rest is history.

The loom was nicely set up in the new studio on an adjustable workbench from Home Depot, alongside my daughter’s version, she took the workshop with me as well.

And there it sat. In March of 2020 I hit the road yet again for Oregon, and of course, the rest is history. I have been home since then, reinventing myself and how I work, not sitting still for one minute, but every time I walk over to that loom, to dust or get a reed, which is in a rack right behind that loom, I look at it and feel guilty. It isn’t like I needed the loom for anything. I have 35 looms, or did at the time, now I have 37. Yeah, I know…

The problem is, I can’t remember what I was doing. There must have been 50 pages in the handout. Everything was tied together, there were four shuttles involved in this specific sample. Five if you count the one with the warp color on it. I even sat down one afternoon and tried to make sense of it. I quickly gave up.

My daughter of course wandered over after some very obvious vocal frustration on my end and looked and said, “Oh, you are doing polychrome Taqueté.” Really? I hate when she does that… And yet, there are times when I think I’d be lost without her.

And then I remember, I’m pretty good at what I do. I’m pretty good at figuring things out when I put my mind to something. I’m spatial and good with sequences and have good deductive reasoning. There is no earthly reason why this should vex me so.

I actually had a free weekend last weekend, with nothing technically on the calendar and I think it rained all weekend so there was really nothing to do outside or in the garden or going for my daily long walk. There was nothing to do but prep for upcoming classes, plan warps, update handouts, update databases, all stuff that forever sits on my to do list but really, I just kept looking at that loom and said, this will be what I do today if it kills me.

And so I unpacked the shuttles, started to study what shed they came out of, and the sequence they came out in, and looked at the information for split shed weaving, and the cheat sheet for Polychrome Taqueté. Just an FYI, this really complex looking thing is done on a straight draw in carpet warp on four shafts. Really. This is not rocket science by any stretch of the imagination.

Seriously, what was my problem…

Within 15 minutes, the lights went on in my head and I suddenly realized that there were only two possible sheds, and that this was a simple structure that was pretty easy to execute. I’m sort of embarrassed.

So I began. It felt good. Really really good. After almost two years, I figured it out. But of course, I had help.

Mulder the shop cat has to be into everything I’m doing.

He finally settles down and curls up on what I’m weaving. Sigh…

Once I encouraged him to move along, I just kept going. I watched the rain from the windows and kept weaving.

I got into a nice rhythm with four stick shuttles on a table loom. Once in awhile I’d realize I made a mistake, and I was proud of myself for being able to go back a row or two.

And by that evening, I was finished the sample and could cut off the warp.

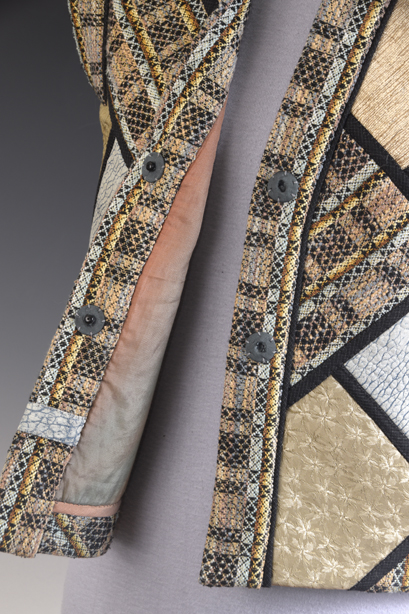

I wet the samples, and a few days later stitched them across and cut them apart.

It doesn’t look like much, but I’m really really proud of myself for figuring it out and finishing. This whole experience has made me realize that there are so many fun things out there to try that I just don’t have enough hours in the day to ‘learn all the things’. This is becoming a goal of mine, to retire from teaching, hence the brain dump of everything I know about creating handwoven clothing into my YouTube channel, The Weaver Sews, and then being able to play, to create, to try all the things. My textile library is ginormous, and my resources and raw materials grow exponentially without much effort on my part. I do not know why…

And in case you were wondering about the progress on restoring the rescued Macomber, parts are starting to roll in from them, and as I get a package, I install the parts. New aprons, a new friction brake on the upper warp beam, 200 inserted eye heddles on each shaft. Lots of other little pieces replaced or repaired. A lamm depressor installed. Just waiting for the bench, and the most critical piece, the dog and spring for the sectional beam ratchet. Somehow that didn’t make it in the original shipment of parts. She is starting to look whole again.

And so dear readers, I made something that was no big deal into something that was overwhelming to me, until I realized it wasn’t and then I was pretty annoyed with myself for letting this thing get bigger than it really was. I wonder if I do that in any other areas of my life…

Stay tuned…