Spray Starch

Yep, the kind in the can that says Niagara on the front.

I will admit that I’m struggling with this mohair yardage. The sett isn’t separating as easily as I’d like and it is pretty slow going. I wander a lot when something is slow going. I look around and think of other things to do, hop up about every four seconds to check email, play with the dogs, do laundry, and on one of my numerous surveys of the studio and the contents while sitting at the loom, I spied a can of Niagara Spray Starch, a relic from probably 20 years ago, just sitting on the counter sort of winking at me…

I looked at the sticky warp and said, why the heck not? What is the worst that can happen.

Can I say my life has been changed? 🙂

Suddenly the sticky warp from hell has been calmed and tempered and it weaves like butter. Instead of a couple of hours a yard, I just blew through more than a yard in about 20 minutes. That includes brushing, bobbin winding and spraying the back of the warp with every advance. So I’m a happy camper and that sort of makes up for the very tedious and physical other project I’m working on.

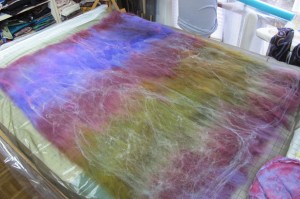

I carefully spent a couple of hours with graph paper figuring out how to cut the 5 yards of silk chiffon into panels for each of the garment sections. I started with the center back. I’m not sure why, it just seemed like a good idea. This panel starts as 50″ x 37″ and barely fits on my table. And so I began laying out the roving onto the chiffon, starting in one direction and adding two more layers in opposing directions. I topped the layout with some streaky shredded silk hankies.

Then I wet it down, with my private stash of Olive Oil Soap, courtesy of one of my husband’s business trips to Israel. This stuff comes right from the Mount of Olives. And then I rolled. And rolled.

And then I tossed it repeatedly in the kitchen sink, heating it up in the microwave occasionally. And I beat it and rolled it some more. And finally, I got it down to the right size, and manipulated it into the shape of the pattern piece. 🙂

It was a hard but good day…

Nice! Progress and lookin’ good too. Way to go on a yuck dreary day.

I once put on a mixed mohair/wool warp that absolutely refused to open. But this was a blessing in disguise: I got to upgrade my only loom from two shafts to 4 shafts! By treadling one shaft at a time, the warp opened purty easy. That was back in the ’80’s.

I love your blessing in disguise Cyndi! And it goes without saying that yes, I’m treadling one shaft at a time. The closer sett still made it difficult to open. But Spray Starch to the rescue!

Daryl,

since you were not felting seamless, why trying to make the felted piece fit the pattern?

You can cut it after felting without fraying, and more felting in some areas might cause uneven and over- felted areas. Just an observation from a nuno-felter. The chiffon and the colors look divine and the addition of the cut-up silk hankies will give the felted fabric beautiful highlights! I would love to see and touch the final garment!

Gisela, my plan was to use the natural organic edge of the finished felt as the seam treatment. Since the front bodice has a dart, I plan to lap the back over the front at the side seams, and use the finished edge of the felt for the lower edge of the jacket and sleeve. The felt is pretty consistent across the surface. The band will also take advantage of the natural finished edge of the felt. That’s why I’m doing individual panels and not yardage.

I want to be where you are now. As it is I am just waiting for 4 ribs to heal and hurt just thinking about felting and a sticky warp. Memories of Northern Wisconsin are flooding back right now.

Gorgeous way the colors are turning out. Love the silk hankies addition! And, remember, the soap on your towel here was hand-made olive oil soap and we can easily get you more.

I remember weaving a mohair wrap for a friend – tried everything to make it easier to weave and ended up threading ends through pieces of straws….. It worked but was a tedious job. The sad ending to this story is ……I mailed it off to Wales but it never did arrive……I have not woven with mohair again to this day :-)……..

Hi Daryl! There is synchronicity in the air- i am weaving with mohair, too. I think that my sett is too loose, though, as my cloth looks very thready. it is 15 EPI. Can you advise what sett you are using? My mohair warp mishap was caused by my Weimaraner, Fog, who likes to chew paper. He nibbled at the paper that I used to separate my warp, It took me 4 hours to untangle the mess and rebeam my warp. Bad doggie!

Thank you, should I ever be tempted by my piles of mohair I will grab my spray can! Good idea.

Great felting…what a day!

The felting is beautiful!

I’ve used spray starch for years (30). Quick, dries fast, washes out easily and certainly easy to use. Works on lots of ‘not so nice behaving’ warps. I spray, then run my fingers back and forth or up and down (however you’re mind is looking at it) to encourage those wispy ends to stick onto its own warp end (not on the next thread over).

I really like your spray starch solution! I’ve used hairspray for the same problem, in the past. Love the felt!

Another great trick for calming sticky mohair is to spray it with hair conditioner. Johnson&Johnson used to make a children’s spray hair conditioner in its “No More Tears” line, but I’m not sure if that still exists. I no longer weave with mohair, but when I did, I would spray the whole area behind the castle with the hair conditioner, let it dry for a couple of minutes, and go back to weaving. As the sprayed ends made their way thru the heddles, they behaved themselves nicely.