Last weekend I taught a three day class, a real honest to goodness three day class. In Indianapolis. From my studio. They all met in person, and I sat happily in my studio, on Zoom for three days straight, with my laptop focused on the classroom, and basically I just hung out, keeping busy watching the screen in case anyone came up to the laptop on their end to ask a question. The whole weekend went swimmingly well, from my perspective.

The group met together to create a vest from leftover fabrics, scraps, handwoven pieces, samples, whatever they had. They got, as part of the class, my 500 vest pattern, and the fusible backing and the pressbar, in a kit shipped to them. I lectured, was available for questions, and because they also employed the use of an iPad, they could carry it over to someone’s work station and really zoom in (pun intended) on what someone was working on, especially pattern alterations, and I could direct the student how to do the alteration I wanted them to do, with multiple people assisting. I could clearly see what they were doing, and the only glitch was because I was looking at my screen, through someone else’s rear camera from their screen, at a person sitting backwards, facing the camera, my orientation was completely off. I found myself prefacing a situation by asking, where is Florida? That seemed to help everyone know the orientation of what I was seeing and I could direct them accordingly.

They were to trace their size pattern and create a test garment, which I evaluated the first morning of class. I’m frantically creating YouTube videos to assist in this, so a lot of the work can be done prior to class. With the assistance of Mary Alice’s iPad, I really felt like I was there.

Anyway, once they had the patterns worked out, they cut a fusible foundation and laid out their pieces. Of course I have no pictures to show, but hope that they will eventually send me pictures of finished vests. Note to self, ask them to take a cell phone shot and email it to me every day. Duh…

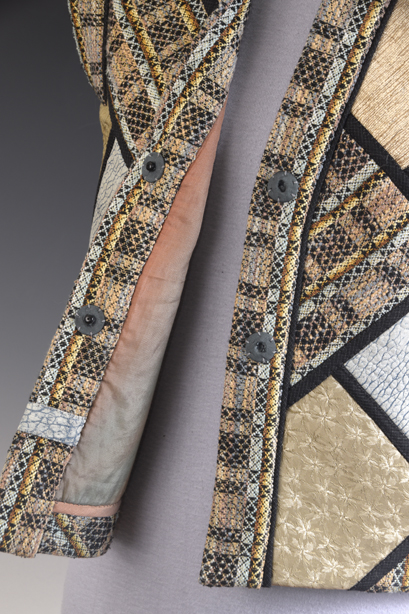

So I created a sample for the class, prior to the class, and finished sewing it up earlier this week. Here are the images from my version of the pieced vest. I blogged about the components of this vest here.

But that’s not the thing that I did, referring to the blog title.

During the workshop, sometime on Saturday or Sunday, in a lull in activity, I checked my email. And there it was. Typically I get at least one email a week from someone who obtained a Tools of the Trade Loom, and has questions about it, because if they Google the loom brand, my name pops up. Probably because, the looms are no longer made, and I talk about them in my blog a lot, since I own 13 of them.

So this email was actually someone who had a Tools of the Trade Loom and was interested in selling it and did I have any idea of what it was worth?

It was a 12 shaft loom. I was a dealer for Tools of the Trade back in the 80’s. I love the loom. I have always loved the loom. And they find me. But I never knew that they made a 12 shaft loom, until I joined my guild and found out that one of my guild mates owned one, she isn’t far from me, she got it from a person in Oregon, and paid a fortune to have it crated and shipped back across the country to NJ. The loom was originally made in Vermont. She knows that if she ever dies, that I will pay her husband anything for that loom.

Anyway, I nearly had a heart attack, I have coveted a 12 shaft Tools of the Trade loom since I found out that Tools of the Trade actually made one. They didn’t make many, but here, I had a letter from someone who had one to sell. I asked how wide, this is sort of important, and crap… 55″ weaving width. Crap. I called my daughter to come into the studio, because I’m still on standby for my workshop, and she walked in and took one look at my face and said, “Who died?” I said, “Worse, take a look at this email…”

Long story short, my lovely beautiful brave, completely competent daughter got up very early Saturday morning, (tough for her since she sleeps till about noon) and ate the Taylor Ham, egg and cheese on an egg bagel I went out and got for her (It’s a Jersey thing…), packed up the Rav 4 with the trailer, and drove 5 1/2 hours to Rochester NY. She completely dismantled the loom down to just lumber, carried it all to the trailer, and reassembled it in the trailer, covering it with a couple of tarps, and tying it down to within an inch of its life.

She said the loom smiled at her when she walked in to see it. It is beautiful she said, barely used, gorgeous condition, but assembled wrong. The entire back beam assembly had been reversed. She corrected that for the trip home, and 5 1/2 hours later, she pulled into the driveway, I raised the bay door, and we moved it into the garage studio, making this shaft loom number 37, and there is no more room in the inn.

Earlier in the week I had a discussion with all my other looms, letting them know that the Macomber was coming to live with us, it was a rescue, and I expected them to play nice together. (See my previous post). Looms can get jealous, and sometimes they get uncooperative, but I expect harmony in my lovely studio. I have a feeling that while I was sleeping there was a bit of mutiny and my 13 Tools of the Trade Looms decided once and for all to cement their solidarity against this Macomber interloper and find me the mother of all looms, the largest one Tools of the Trade ever made. There is no other explanation…

And so dear readers, I am in the process of assembling the shafts, correcting some things that weren’t quite right. I’m putting 225 inserted eye heddles on each shaft, though that number is fluid. I have over 100 shafts in my studio that all take the same size heddles and I am constantly moving heddles around. I’m very efficient at this, every shaft is clearly marked with how many heddles it has, and I’m very careful and organized at how I accomplish this.

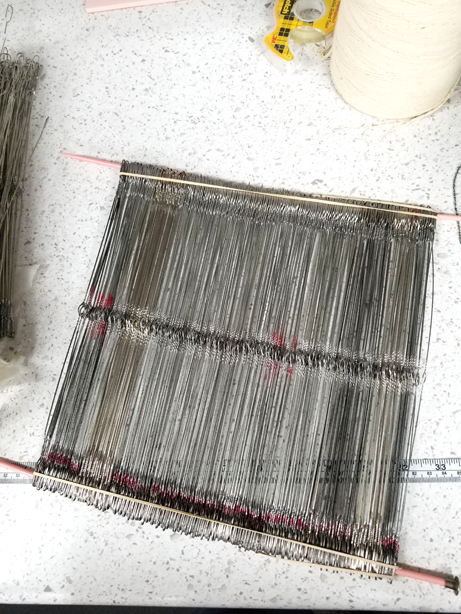

So I opened a bag that came with the loom and found this…

Sigh…

So for the weavers who are reading this, we need to have a discussion on heddle etiquette. I’ve taught many many times in weaving studios, and taken workshops involving round robins, so I’m working on other peoples looms. There seems to be a lack of understanding in the weaving community about heddle etiquette in general. NEVER NEVER NEVER just remove heddles and toss them into a bag. First of all, that pretty much ensures that the fine wire heddles will end up bent and misshapen. Secondly, each heddle is canted a specific way, and they all must face the same way. Heddles are canted so that they nest close together when a loom is warped.

THEY ALL NEED TO FACE IN THE SAME DIRECTION… I spent hours, days really, sorting and replacing all of the heddles on more than 100 shafts when I was involved with the donation of a dozen Macomber looms from William Paterson University to Peters Valley School of Craft. You cannot imagine what a mess. Apparently no one got the memo that all heddles had to cant in the same direction. Towards the right if you are right handed and towards the left if you thread with your left hand. You can easily make a loom cant left by flipping the heddle bars on any shaft. Takes about 15 minutes, depending on how many shafts.

NEVER NEVER NEVER just remove heddles and toss them into a bin or bag. Heddles are carefully slid onto holders, some use stitch holders in knitting, I’m particularly fond of old pairs of steel or plastic knitting needles. With a couple of rubber bands, I can effortlessly slide heddles off and on the heddle bars, storing them in a tidy fashion, canted in the same direction and they can easily move from one loom to another.

I spent about an hour per shaft tonight, resetting the heddle bar hooks, wiping down the shafts with Howard’s Feed and Wax, and fitting 225 inserted eye heddles all canting in a right handed manner. I’ve only got two shafts done. This will take awhile.

Meanwhile, it is Mother’s Day. My daughter gave me the ultimate gift by volunteering to drive to Rochester NY to pick up this beloved loom, and I let her sleep until noon of course. Once she was up and functioning, we headed out to the garden to do the Mother’s Day weekend planting of the vegetables. Our zone is pretty much safe to plant after Mother’s Day. Tomatoes, basil, peppers, cucumbers, all went in amongst the radishes, turnips, kohlrabi, and other greens. I’ve been eating garden salad every day.

I thinned the turnips, kohlrabi, and radishes, and brought in a bowl full of thinned baby greens, took a handful, washed and destemmed, and sautéed them with a couple of chopped anchovies for a nice veggie side dish with my turkey burger. I know. I love anchovies. Turnip greens sautéed with anchovies is just the best… I put in a whole flat of Marigold’s, and then scrambled to clean everything up because it just started raining. It has rained steadily on our new plantings well into the evening. Life is good. Or wet. Depending on your perspective.

And so dear readers, for those of you who care for another living breathing thing, be it a loom, an animal, a person, a child, a parent, you are all mothers. And for those whose mothers have gone on to another life and another world, know they watch over us, and guide us, and give us hope, and comfort and really good memories.

My delightfully curious cat couldn’t wait to explore that stack of shafts spanning the counter over the sink. Our fur buddies keep us smiling and on our toes.

So I did this thing, and now it is tough to move around in my studio, but this thing I did makes me really really happy and I am accumulating lots of good loom karma. I’m still waiting on the shipment of parts to get the Macomber loom functioning, and I am already winding a warp for one of the other empty looms. There is always a loom needing a warp. Sort of an ongoing thing in our house…

Stay tuned.

OMG! You may need to add an extension to the garage!

I gasped out loud when I saw those heddles! Another great save.

You are amazing! Love my Tools of the Trade loom, too. 8 shafts, 36” wide. Looms are collecting here at Shear Luck Farm in NW Wisconsin. I don’t have sheep anymore so the sheep barn is being converted to a studio. 13 32 feet. I am afraid it won’t be big enough. So far I’m planning a dye area, fabric prep and sewing area and space for the two biggest looms. I should call you for suggestions some day soon, plus I’m having a little trouble with the shed on my ToT. I think it used to be a bigger… Read more »

You mentioned that you will need to wait for your Indianapolis class members to send you photos of their work. Please excuse me if I’m missing your point, but do you realize you can take screenshots of what’s on your computer screen in the moment, so that you can essentially create your own photos of their work? Also, as I’ve mentioned before, I’m just fascinated with your posts and your vast amount of weaving/loom knowledge. Just call me a faithful follower and weaver-extraordinaire wanna-be.

Glad the Indpls. workshop went well. I am in the Indy guild, have taken classes from you and would have liked to do this class, but could not fit it into my schedule. Our Guild meets next week and I will hear all about the class. I felt guilty buying a third loom, but then I do not weave at the rate you do! Enjoy your garden. Cindy Wilson

Daryl, Thank you for the heddle scold! I have helped manage our guild’s looms and things have mostly been OK but not always. I was tickled to realized that I store heddles just like you do but I use long, bamboo skewers: cheap by the 100’s. And I cross each rubber band to make it stay better. Love the pieced vest. I have to learn how to sew by June 1 since Lynn Lovett wouldn’t let Fred into the class we have at CHT: too much garment changing… We will make a muslin to take to class and then I… Read more »

Forgot to mention: I have a cucumber already and about 50 green tomatoes. And dozens of tomatillos. And my eggplants starters are setting their first blooms. Thanks for the greens and anchovy idea!

OMG I laughed out loud at that pile of heddles! What a nightmare! But you will be the good Heddle Steward and set them right,

I know I have said this before but I just have to again….. I love, love, love your blog posts.

Congratulations on your fabulous find, your wonderful daughter, and your lovely Mother’s Day Garden. Your karmic glow was pulsating as I read! Oh those hay-wired heddles! I found a big bag of bright colored long zip-ties in my husband’s stash and stole them for my heddle moving projects. They work so beautifully as they are flat and just about the width of the heddle rails on my Schacht. I usually keep track of my shaft heddle counts in a book, but I’m going to start using painters tape on each section of my shafts as the Schacht has those clips… Read more »

Wonderful! Keep us posted on your first project of the new 12 shaft.

Hi I just found your site, and thank you for tips on the heddles-I did just that awhile ago took a bunch off and tossed them into a basket-Once this weaving is finished I will go back and straighten out all of these so they sit in the right direction–I knew as soon as I did that not good

Great story! Some mighty good tips contained therein, too…especially the one about using old knitting needles to hold heddles. As an avid knitter I have plenty of those. I wish you many, many years of joyful weaving on your “new” loom!