The days pass quickly in a routine that is pretty pleasant truth be told. I’m not missing traveling, not missing even leaving the house. I see friends and family enough via zoom, and with all the remote lectures I’m giving, I feel as though I’ve just attended the world’s largest weaving conference. Each day I bounce around to some part of the country, and each lecture there are old friends and familiar faces in those tiny boxes on the screen. I’ve been corresponding with someone in MO, who was supposed to take a workshop with me in August in Kansas, but appeared in a lecture in western MA. We weavers get around…

Having my daughter here, working with her, developing new content, shooting a new video every Friday for my YouTube site The Weaver Sews. It has kept us busy. The biggest challenges are keeping the animals quiet, and hoping the landscape people don’t come through in the middle of filming the way they did last Wednesday in the middle of a class I was teaching remotely. Those leaf blowers right outside the garage doors were pretty noisy.

So the election in the US is Tuesday. I don’t hold hope that things will be resolved by Tuesday night. I don’t hold hope that things will be resolved for a very long time, no matter who is declared the winner. I’m sad for the polarization, I’m sad for the divisive language used by both sides, I wish we could all get along and move forward. We are in the middle of a couple of international crises and I’m a firm supporter of science (having a daughter with a science degree means I can’t even cook without a science perspective thrown into the recipe), and no matter the results, I hope moving forward that we as a nation can come together to solve some of these major issues. I’ve just heard of another weaver who lost their entire studio to one of the fires in Oregon. She took a workshop with me just in March of this year, my last stint before the world shut down. I sent her digital files of everything we could piece together that she lost from my workshop, but that doesn’t replace yarn, samples, looms, weaving equipment, spinning wheels, and a life time of knowledge in physical form. My friends in California, Oregon, Washington, as well as Louisiana have taken the brunt of this year’s climate disasters. I wish the world had a plan moving forward. For me, I voted within 24 hours of receiving my mail in ballot (only mail-in voting in NJ this year because of the pandemic), so on Tuesday night, I’ll be teaching remotely for a guild in Toronto. I can only do my best to keep moving forward, being kind, paying attention to the science, fighting for equality for all, and embracing my countrymen no matter what and who they are passionate about.

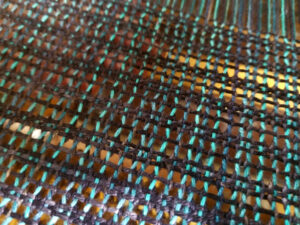

Since Tuesday night’s lecture is on Doup Leno, a technique I wrote about a couple years ago for Heddlecraft Magazine, (January/February 2019), I needed to have something set up for a live demo. The warp that I had been using was mostly used up. So I rewarped this week, with a couple of handdyed skeins of cashmere I had sitting around, one a dark and the other a variegated turquoise. The goal is a couple of scarves, the leno structure will keep them lacy, but the structure will hold together.

That said, I’ve been rather busy with my simple days. Simple means I can fill my days up with juggling 40 things at once, because I can’t imagine a day when 40 things aren’t happening simultaneously!

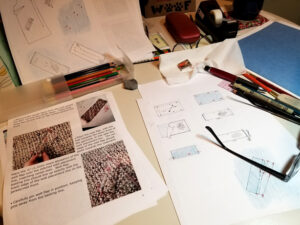

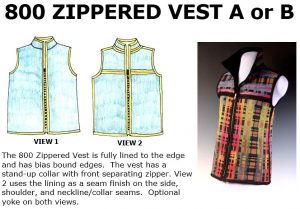

I’ve been working for the last couple of weeks on a new project. The last two vests I made both had welt pockets. It has been on my to do eventually list for a couple of years. I finally sat down, designed a diagonal entry welt pocket and then once I did a few of them, drew illustrations and wrote up the 12 page directions.

Now you can actually purchase the Welt Pocket Variation as a download. The download contains the 12 page heavily illustrated directions, the two pattern pieces full size for the welt and pocket, and replacement pages for the 100 jacket, 200 jacket and 800 vest. By substituting the pages in the pattern digital files, you’ll see where the pocket goes. So if you’ve purchased the 100, 200 or 800 vest, you might enjoy this variation. Of course it will work for any jacket or vest you make from anyone’s patterns, you’ll just have to figure out where to position it.

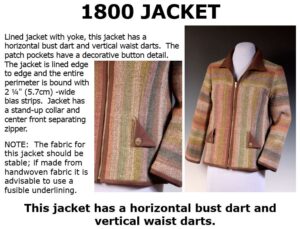

The second vest I finished is the one I’ve been using for demonstrations during my last few YouTube videos. The fabric was a remnant I bought somewhere, can’t remember, but it was a gorgeous sleezy Chanel type tweed, really challenging to work with, like your worst case handwoven. My handwoven fabrics aren’t nearly as challenging! I made up the 200 jacket but left off the sleeves, bringing the lining to the edge of the armhole. With the shawl collar and welt pockets, it is a much different look than my other vests.

I realized of course that I haven’t updated my gallery on the website with the last couple of pieces I’ve made, the Summer Rain Top, and of course the leopard trimmed and lined Confetti vest shown above. It is much more important to be timely in those updates because my daughter references those details and images when she creates the show notes for each video I do. We took one of our guest rooms, since we aren’t getting a lot of guests (none actually) and turned it into a temporary photo studio. So I popped the Summer Rain top onto the dressform, and perched it on top of the table to take a quick shot of the top. The free draft for the fabric for this top, using Silk City Fibers is available here. The pattern is a combination of my 1000 Swing Dress, very modified to take out the “swing”, and the armhole and sleeve from my 200 Jacket.

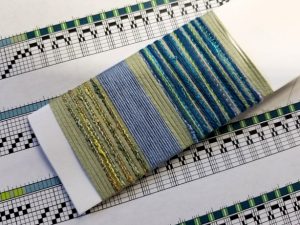

Meanwhile, now that all my looms are full, I filled them up for the HGA remote studio tour the beginning of October, I need to start clearing looms because I’m getting more ideas of stuff I want to weave. So I cleared one of the table looms first. This one had a test for Silk City Fibers, their Supermerino yarn, sett in an 8 dent reed, plain weave, to simulate what one would experience with a rigid heddle loom set up. One was a single end in an 8 dent reed, single weft, spaced a little far apart for my taste, but that was the point of the test. I gave that one to Silk City and kept this one, which is two ends together in an 8 dent reed with a doubled weft (I used a double boat shuttle for that scarf). Supermerino is a superwash yarn. It doesn’t say that in the description, but it doesn’t full at all when washed. The result is actually quite soft and lovely, and I’m glad they let me keep one of the scarves. I suspect I’ll be venturing outside a bit this winter, if only to walk the property and pick up dog debris, and I think this will be quite warm.

I did a round robin sort of day earlier in the week, I wove a yard of two on each of the other floor looms, just to get them moving forward. I can probably just sit and weave and finish off a couple of them in a day or two. To have time to just sit and weave is such a gift. And that means I’ll have yardage to sew. And empty looms to rewarp…

There is this one, which has been on the loom for way too long. The yarn is Noro Taiyo Lace, a pain to work with but really beautiful in its gradient effect as the weft. 4 shaft, warp is vintage Harrisville singles Shetland wool and vintage Maypole Nehalem worsted. I’ve probably got less than two yards to go…

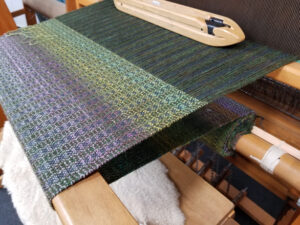

This is another test for Silk City Fibers, their new Cotton Bambu yarn mixed with their Chenille Tapestry yarn. I modified an 8 shaft shadow weave draft, it is a bit slow to weave because of the two shuttle complicated repeat but it is moving along nicely.

And this one is also using Silk City Fibers, their new Nile cotton tape mixed with Skinny Majesty variegated. The weft is their Wool Crepe. I can’t wait to weave off this fabric, it is weaving like butter and I want to make swing dress out of it. Over a black turtleneck, this could be fun for winter, something new to wear, even though I don’t go anywhere and only dress for the upper third of my body for remote Zoom meetings. And for the videos, I get to dress up, put on makeup and look remotely professional, but everything has to be 2-piece to support the remote microphone pack clipped into my waistband.

Days are cooler now, we have finally had frost in NJ. I cuddle up with the gas stove in the living room, and a 1000 piece puzzle and some wine in the evenings, or watch late night political satire on the TV with my daughter. We need to keep laughing, we need to surround ourselves with art, humor and good food and drink. And of course animals, there is a cat asleep on my lap as I type, with one paw draped over my typing hand. And yarn and good books. I have all of that, and new flannel sheets coming this week from LLBean. My daughter stole my other set. Life is OK for now in my small neck of the world. I quietly keep making up new stuff, and keep an eye out for important things to know about.

See you all on the other side of this election, stay safe, wear a mask, and don’t forget to vote…