Periodically I go through my phone and dump all the photos into my computer which then get backed up in the cloud. It keeps my phone storage reasonable, and then I can pull from those images for a blog. I feel like I only put up a blog a couple weeks ago, and there were so many photos in my phone to upload this morning. Meaning I’ve been busy…

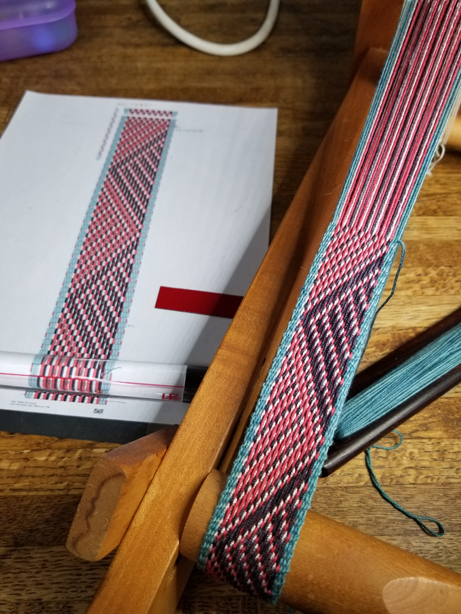

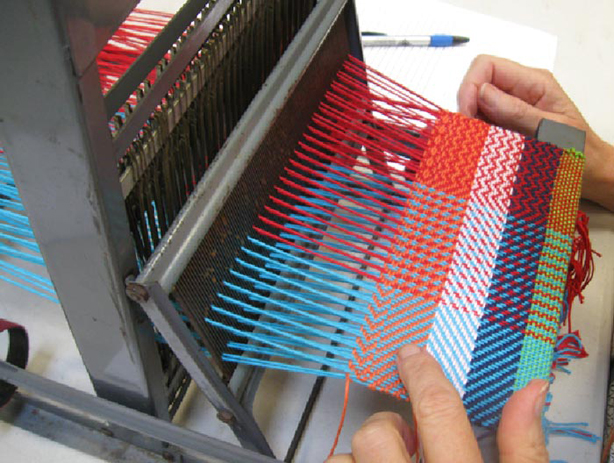

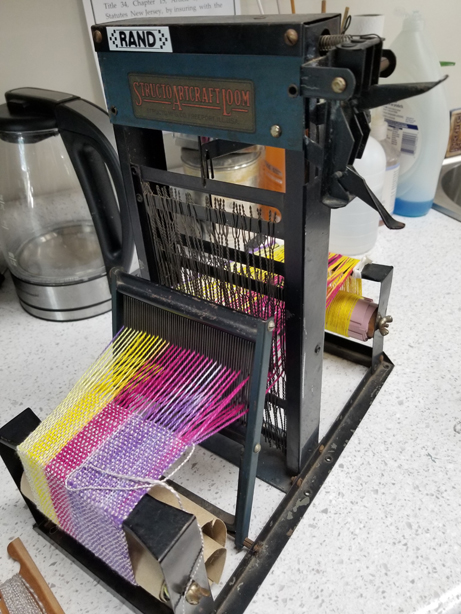

I had a couple of private students booked for this past week, they arrived, and we got right to work. They were here to learn to weave yardage, and design with combination structures. They brought bins of yarn, and we supplemented with whatever I have. And I have a lot.

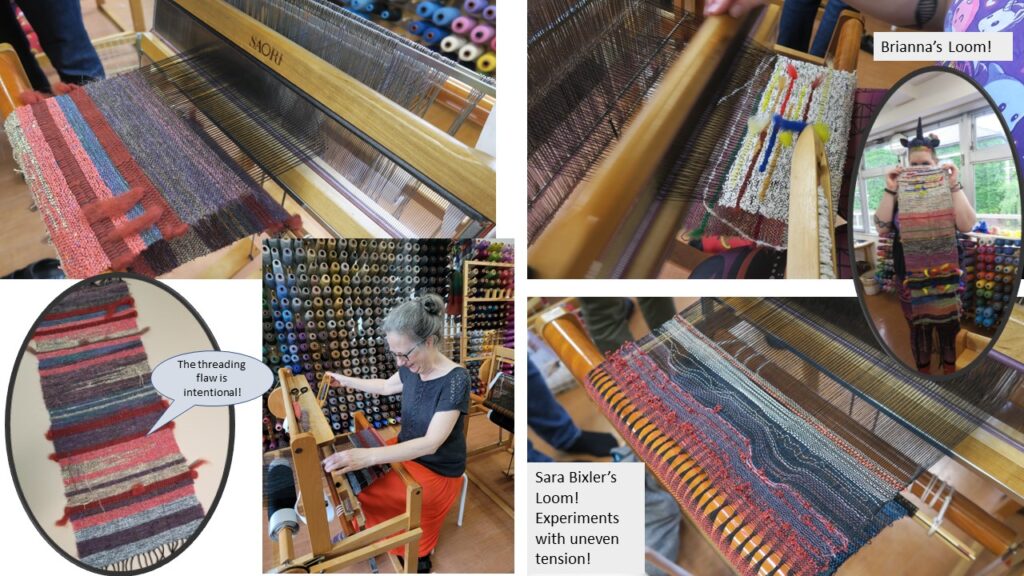

So here are my two students working on two of my looms, and the yardage they were creating. I adored both of them, we had a great time together.

What this all actually meant, was that I needed to have a couple of looms for them to choose from for their projects. If you’ve been following my blog, you know that all my looms have warps on them. I’d been systematically clearing the looms, leaving the finished cloth on them, so they didn’t feel naked, and because Mulder, the studio cat likes to use the fabric on the loom as a hammock. He has his favorites…

I had warps on five of our floor looms, I can’t do anything about my daughter’s looms. But I worked systematically and in the days leading up to the students’ arrival, I furiously wove off the chenille yardage. This meant that they could pick which loom served their physical needs best. Once they arrived, they tried out each of the looms, and I cut off the finished yardage so they could use those looms, while they wound their warps.

We needed to resley one of the projects, it clearly needed a denser set, so that meant I had to clear another loom they weren’t using to get the only 9 dent 25″ reed in the studio. It has been on my list for awhile to get a couple more, but I can never find 9 dent reeds used. Which means a lot of money…

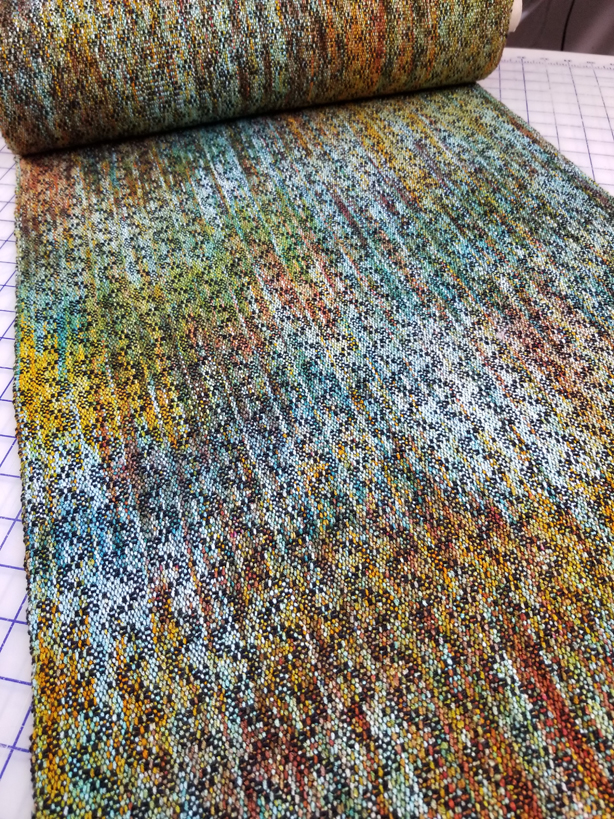

And so, while I was at it, having already cleared three looms, I went ahead and cleared the remaining two. I had a nice pile of handwoven yardage on my ironing board.

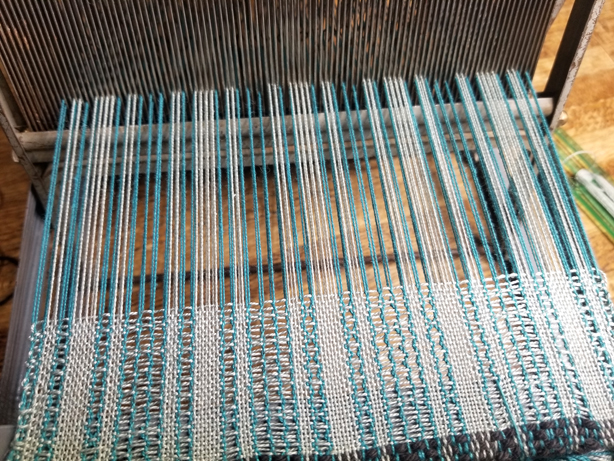

I’ve washed and dried everything but the combination structure fabric, on my list to do this week. The chenille log cabin yardage is gorgeous.

The ice dyed warp I wove in a crackle structure is really beautiful and I’m mulling ideas for both of these yardages.

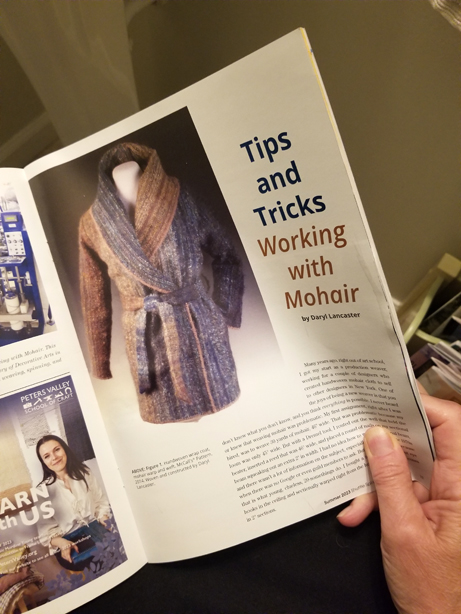

I haven’t washed the mohair yardage, I may climb into my bathtub with it as I left the fringe at either end, and I’m not sure what I want to make yet.

Mulder is pretty pissed that I’ve cleared the looms. He doesn’t have his favorite hammocks anymore. He is waiting…

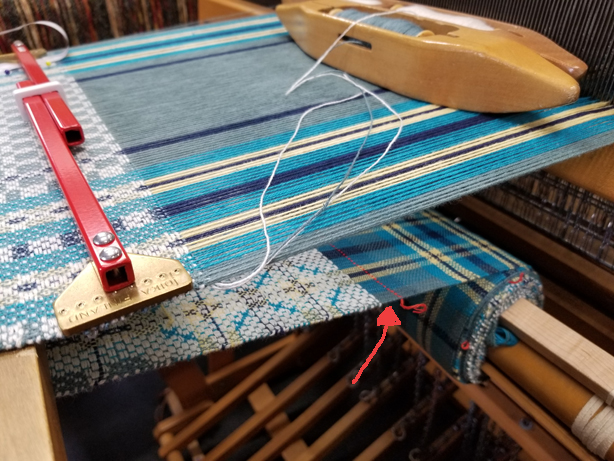

And I pulled the finished kitchen set, four placemats (I had enough yardage to make a fifth), four plain weave napkins, and a long table runner, 6 shaft summer/winter, from a Webs design, Complete Kitchen Set. They are so gorgeous. I’m particularly proud of these. Apparently the design is from a Jacob Angstadt coverlet book, which I have, and I’m really hoping to get a chance to sit down and play with the profiles in that book and see what else I can come up with. Meanwhile, I just followed the directions in the draft book I bought from Webs. The reverse side is just as much fun.

Interesting thoughts running through my head though, as I washed and dried the entire roll, and then planned to cut apart after the fact. The directions say to weave a sewing thread seam allowance for the header. I know this is a common practice in a handwoven turned hem, to reduce bulk, but since I typically weave yardage for kitchen towels, and then cut apart based on the length of the finished yardage, I hadn’t actually tried this method. When I took the roll of fabric from the dryer and went to cut apart on the red line, I realized that I had grabbed polyester sewing thread, in a perfect match, and that poly sewing thread (which is what I use for sewing garments) doesn’t shrink, so the sewing thread seam allowances for the hems were wrinkly.

They still hemmed fine, but in my head, I’m like… “Stupid me, I should have used cotton…” But over the week I’ve been starting to hem by hand, I thought, wait a minute, cotton sewing thread isn’t designed to shrink in the wash, it is sort of pre-shrunk. You can’t sew a garment and not be able to wash it… So I’m sort of wondering what others do, the poly mushed up fine in the turned hem, but I’m thinking that a 20/2 cotton would have made more sense in a mid grey, rather than sewing thread. The body of the piece was 8/2.

In my last post, I mentioned the horrific mistake I made when I started the runner. I forgot to weave the header, I just wove the sewing thread seam allowance. I posted a photo of the situation.

A reader asked in the comments if I would elaborate on my planned fix, since they weren’t a garment maker (I mentioned a false hem), and so here is what I came up with. In all fairness, I did weave the seam allowance, so that was there, and I was able to recognize my mistake early enough, that when I finished the runner, I wove a section for a header with a sewing thread seam allowance on either side.

I pressed under the seam allowance on both long edges of the false header, and then encased the seam allowance from the runner.

I carefully pinned.

I sewed both sides of the false header by hand and seriously you absolutely can’t tell it was an add on. So the runner is finished, and one placemat and napkin are hemmed. Lots more to do. I love to sit at night and listen to classical music and do busy hand work. So I’ve been itching for a good handwork project.

Side story. My mom, who is 92 and gave me the foundation in sewing garments that led me to where I am today. Over the years as her life and lifestyle changed, no longer needing a fresh new seasonal wardrobe and having no children left to sew for, as we all grew up and sew for ourselves, she moved onto other textile techniques that could fill her creative needs. When my dad was alive, and they drove back and forth to Florida, she picked up counted cross stitch, since it was portable. I have some of her gorgeous counted cross stitch pieces all over the house. When my dad passed, she took up quilting, since she stayed in one place and could easily spread out. My dad hated clutter. (I always wondered how he tolerated our dining room turned into a sewing room for all those years I was growing up…)

Anyway, mom was pretty into the quilt block of the month club at Joann’s and many of her finished quilt blocks of the month cover my beds. I will admit, buying a kit does prevent stash acquisition build up, and it made sense for her. Years ago, she invested in a 9 block quilt block of the month that featured very detailed appliqué work of cats.

She had finally pulled out the first block and started figuring out how to actually trace off the small pieces and cut them from the assigned fabrics, when she fell right before Thanksgiving last year, and broke her shoulder. It has been a long year of recovery, and I completely get it, having gone through it myself a year before, but I’m in my 60’s and bounced back pretty quickly. At 92, she now needs aides at night, and she had to put all her projects away, so there was a room for the night aides to live. She understood that this cat appliqué would never get made. On my last visit, she handed me the whole bag and asked if I would make it…. Sigh…. You can’t be serious, was the first thing that popped in my head. I showed my daughter, who showed some slight enthusiasm, but she has so many creative irons in the pot, I can’t see her making any progress, at least in my lifetime.

Coincidentally, my students this weekend were both needleworkers. One of them looked at the quilt block packages and thought she had made one of the blocks and didn’t sound hugely enthusiastic. There are about 50 appliquéd pieces for each one, some as tiny as a pin head, and frankly, though I know how to hand stitch, and enjoy it, this isn’t my forté. My student suggested a method of cutting the pieces out using a file folder template, coating the edges with spray starch, and then ironing the seam allowances over the template to allow for easier appliqué. She even showed me a Clover iron with tiny tips specifically for this purpose. I ordered and it came the next day.

So spurred on by a way out, I studied everything, redid the tracing and how I would transfer the markings to a file folder, and actually started. The pieces are numbered in the sequence you have to apply, because they overlap in most areas. I managed to get the first flower appliquéd on, and have pinned the second flower. I dare say I’m enjoying this. I’m a fixer of puzzles, I do one every week, and this is really no different. I didn’t design this, I’m just executing it, like my kitchen set above. Following someone else’s directions is a challenge all on its own, and you learn a lot. I don’t know if I’ll ever finish all 9 blocks in my lifetime, but I’ve always been about process, and not the finished product, so this satisfies a need to just sit quietly and hand sew…

I actually managed to get together with friends on a couple of occasions and enjoy an outing. My college friend Carol, flew in from the west coast for a week down the shore and I joined her and her husband for an overnight. We went to Barnegat Light, at the end of Long Beach Island, and took a lovely boat ride around the light house and off into the Atlantic.

And we went to the beach late at night to watch the moon rise over the water.

I got together with a couple of friends more locally and one of them had an extra kayak. I’ve never been kayaking. I know, my son tells me I have to get out more. So here I am on a still lake, in northwestern NJ, with friends I care about in a Barbie pink Kayak. It doesn’t get any better than this…

And in-between all that other business over the last couple weeks, I managed to mordant some wool and some silk/wool commercial yarn and dye it with marigolds from my garden. I’m looking to see what else is around I can harvest.

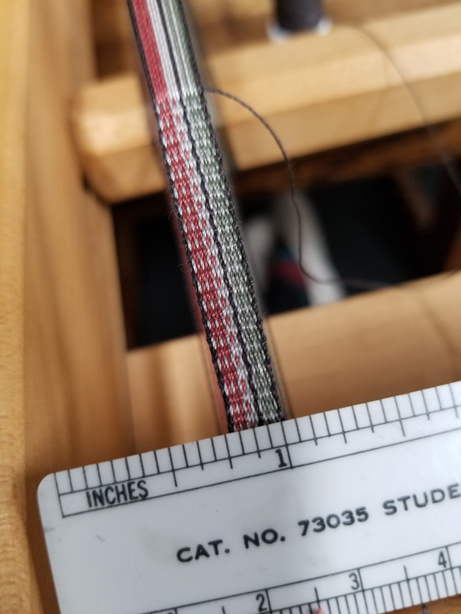

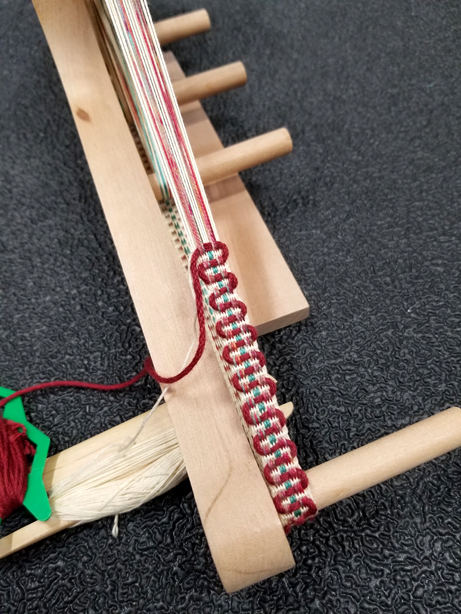

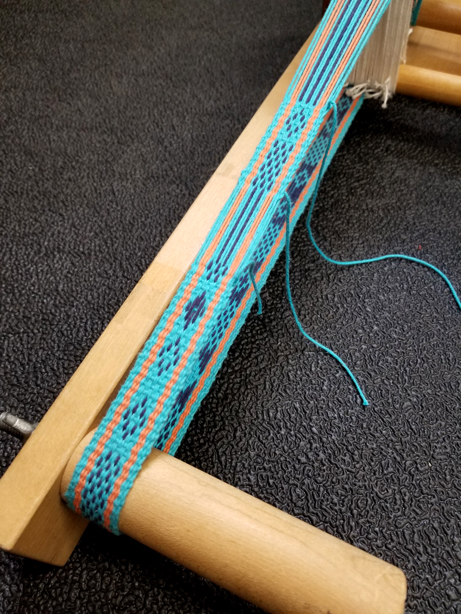

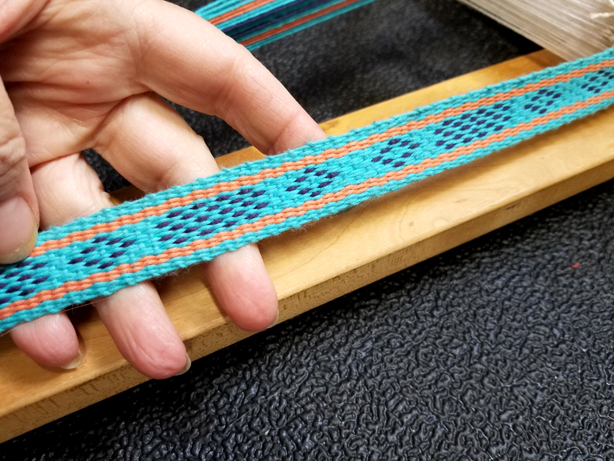

And I dug through a box of kumihimo disks and projects which I kept for teaching purposes. I would start a pattern, and leave it in progress so I had something for teaching. It is time to clear all those disks and move that equipment on. So I’ve finished one braid…

…and picked up another disk with a pretty square one on it. This took me a bit to figure out how to do it, but I’m nearing the end of that braid as well.

I have some writing projects to get through, and some guild work coming up (rewriting the ops manual, always a challenge), but the weather is starting to cool, and I’m looking forward to the fall.

I’m so stressed for all my friends who live in areas that are currently scorched or flooded, and am hoping that you are all OK and that your lives will come back together again. In NJ, where we are used to flooding, we have had something like 13 tornados already this year, we never get tornados. Each one has wreaked havoc on a community. I’m frightened for the future of the planet, and wish there were an easy fix. So I do what I can in my own corner of the world, and keep my hands busy, the best antidote to the stresses of life we can’t control.

Stay tuned…